Ultra-low-temperature plasma organic waste recycling method and device

A technology of organic waste and plasma, applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of over-treatment and waste of energy, and achieve the effects of energy saving, convenient use, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

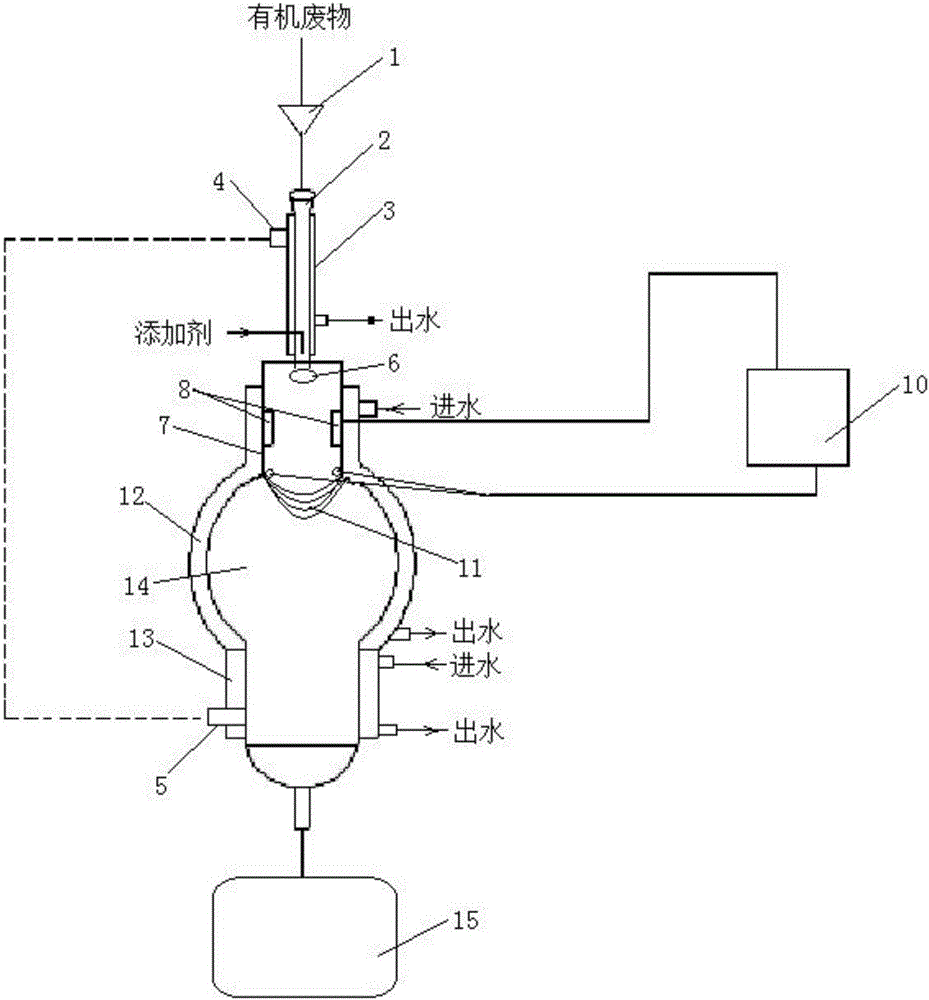

Method used

Image

Examples

Embodiment 1

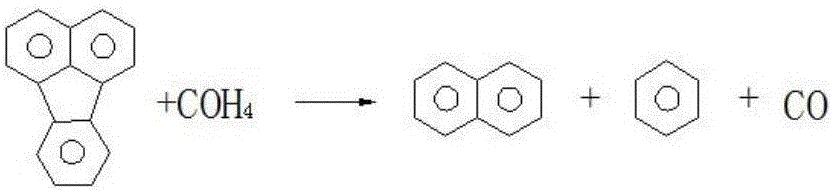

[0038] Anthracene-containing organic waste enters the feed pipe through the raw material pump, is heated by the steam jacket to 90°C, and reaches the distributor after being mixed with the additive at the end of the feed pipe; the additive is methanol, and the molar ratio of the additive to the organic waste is 1 :1;

[0039] The temperature in the plasma reaction chamber is controlled at 750°C. The anthracene in the organic waste breaks bonds and combines to form naphthalene, benzene and carbon monoxide, and completes partial plasmaization. The solid matter generated by the reaction of naphthalene, benzene and other components of the organic waste undergoes plasma reaction After the lower part of the device is cooled down to 150°C, it is discharged from the bottom material outlet to the material storage tank. The reaction formula of the above process is as follows:

[0040]

Embodiment 2

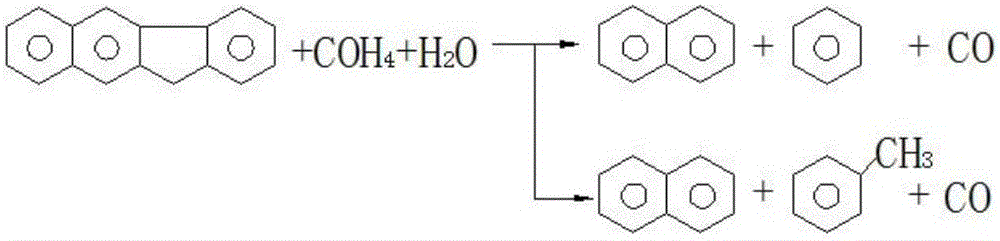

[0042] The organic waste containing benzofluorene enters the feed pipe through the raw material pump, is heated by the steam jacket to 92°C, and reaches the distributor after being mixed with the additive at the end of the feed pipe; the additive is methanol, and the molar ratio of the additive to the organic waste is 1:1;

[0043] The temperature in the plasma reaction chamber is controlled at 780°C. The benzofluorene in the organic waste breaks bonds and combines to form naphthalene, benzene (or toluene) and carbon monoxide, and completes partial plasmaization. Naphthalene, benzene (or toluene) and other organic wastes The solid matter generated by the component reaction is strongly cooled to 160°C in the lower part of the plasma reactor, and then discharged from the bottom material outlet into the material storage tank. The reaction formula of the above process is as follows:

[0044]

Embodiment 3

[0046] The organic waste containing fluorene enters the feed pipe through the raw material pump, is heated by the steam jacket to 89°C, and reaches the distributor after being mixed with the additive at the end of the feed pipe; the additive is methanol, and the molar ratio of the additive to the organic waste is 1 :1;

[0047] The temperature in the plasma reaction chamber is controlled at 7650°C. The fluorene in the organic waste breaks bonds and combines to form benzene, toluene and carbon monoxide, and completes partial plasmaization. The solid matter generated by the reaction of benzene, toluene and other components of the organic waste passes through the plasma reactor. After the lower part is cooled down to 150°C, it is discharged from the bottom material outlet to the material storage tank. The reaction formula of the above process is as follows:

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com