Plastic detection sample cutting device

A technology for testing and cutting samples, applied in the field of plastic testing sample cutters, can solve the problems of troublesome cutting process, low quality of cutting samples, inaccurate size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

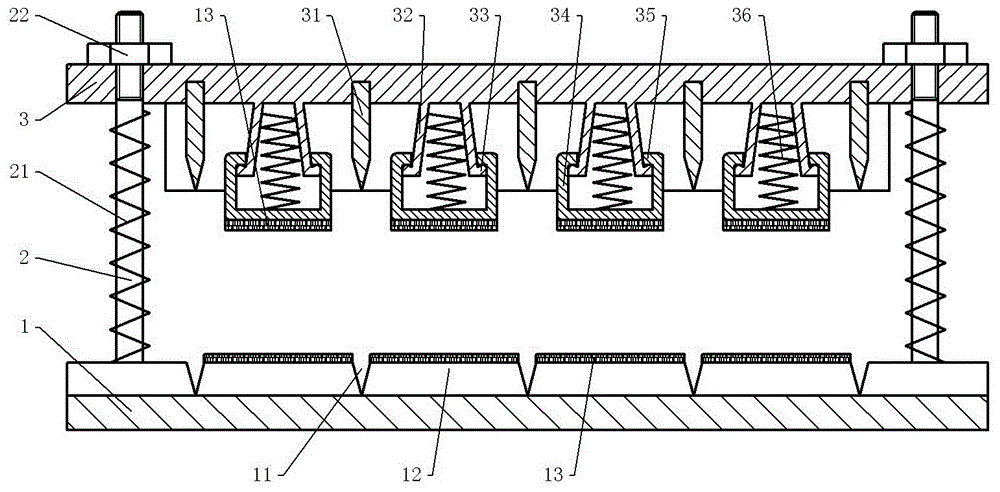

[0018] The reference signs in the accompanying drawings of the description include: base 1, pillar 2, knife holder 3, knife groove 11, material distribution grid 12, buffer sponge 13, return spring 21, limit nut 22, blade 31, engaging piece 32, Limiting rib one 33, pressure material column 34, spacing rib two 35, top pressure spring 36.

[0019] The embodiment is basically as figure 1 Shown:

[0020] The plastic test sample cutter includes a base 1, a pillar 2 and a knife holder 3; there are four pillars 2, and the pillar 2 is integrally formed with the base 1, and the pillar 2 is perpendicular to the base 1, and the knife rest 3 is slidingly connected with the pillar 2, and the pillar 2. A return spring 21 is set on the upper cover. The return spring 21 is located between the base 1 and the knife rest 3. Threads are provided above the pillar 2, and the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com