Fiber internally-reinforced wood plastic product with high impact resistance, high folding resistance and high size stability and preparation method thereof

A technology for dimensional stability and wood-plastic products, applied in the direction of wood layered products, chemical instruments and methods, layered products, etc. To avoid problems such as decline, achieve good dimensional stability when heated, improve interfacial compatibility, and optimize performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

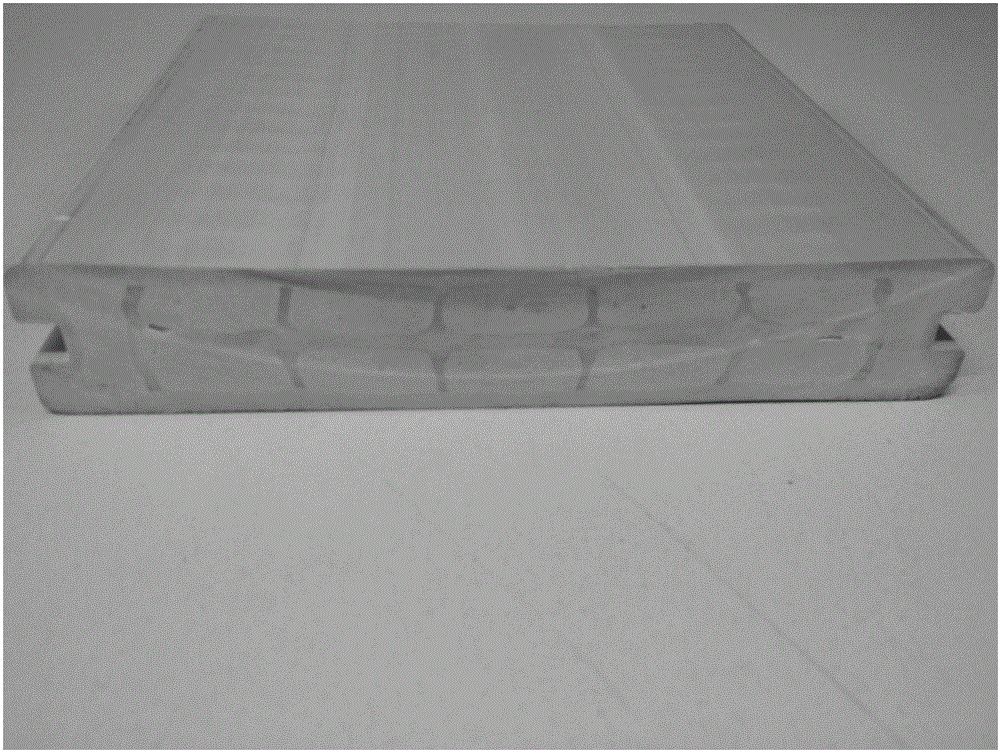

Image

Examples

preparation example Construction

[0045] A method for preparing a high-impact, high-bending, and high-dimensionally stable fiber-reinforced wood-plastic product, comprising the steps of:

[0046] 1) Mix the surface layer raw materials evenly;

[0047] 2) melt extrusion granulation to obtain surface layer pellets;

[0048] 3) mixing the dried core layer resin with other core layer raw materials evenly;

[0049] 4) melt extrusion granulation to obtain the core layer pellets;

[0050] 5) Composite and co-extruding the surface layer pellets and the core layer pellets to obtain fiber reinforced wood-plastic products;

[0051] Alternatively, the preparation method comprises the steps of:

[0052]1) Prepare powdery surface layer raw materials;

[0053] 2) Mix the dried core layer resin with other core layer raw materials evenly;

[0054] 3) melt extrusion granulation to obtain the core layer pellets;

Embodiment 1

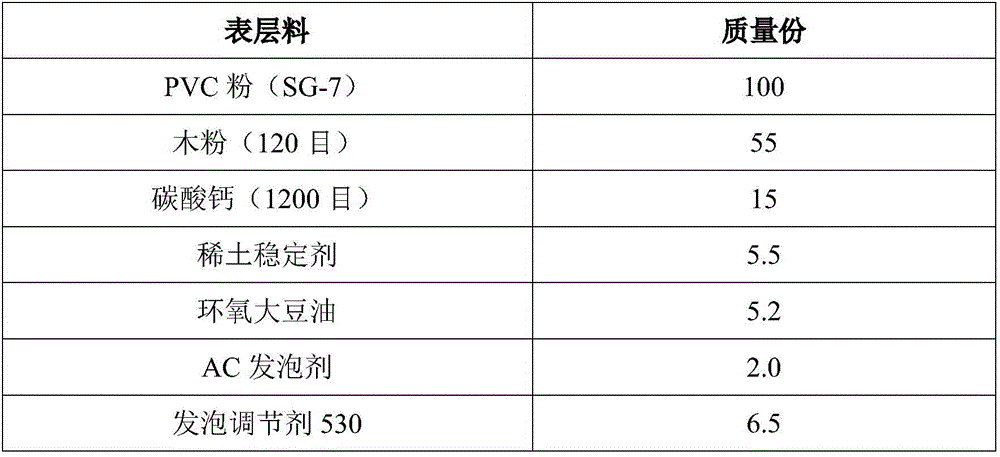

[0071] The raw materials of high impact resistance, high flexural resistance and high dimensional stability fiber reinforced wood-plastic products are composed of the following components:

[0072] Table 1: Raw material composition of internally reinforced wood-plastic products

[0073] Surface material

Embodiment 2

[0075] The raw materials of high impact resistance, high flexural resistance and high dimensional stability fiber reinforced wood-plastic products are composed of the following components:

[0076] Table 2: Raw material composition of internally reinforced wood-plastic products

[0077]

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com