High-stability calcium hydroxide/graphene nanocomposite and preparation method

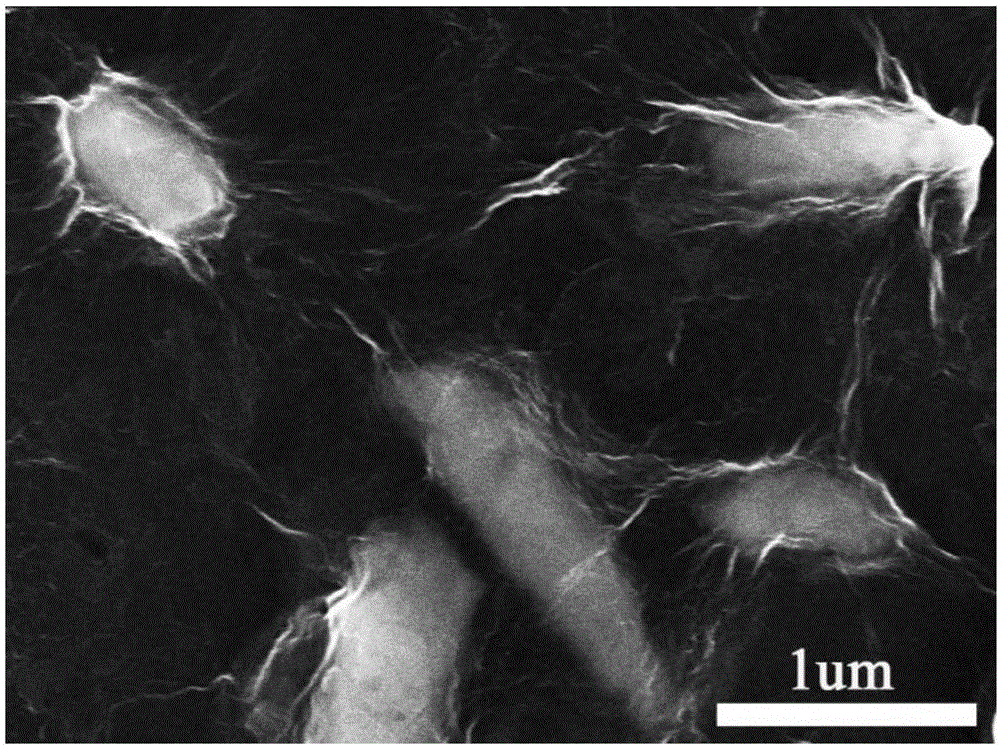

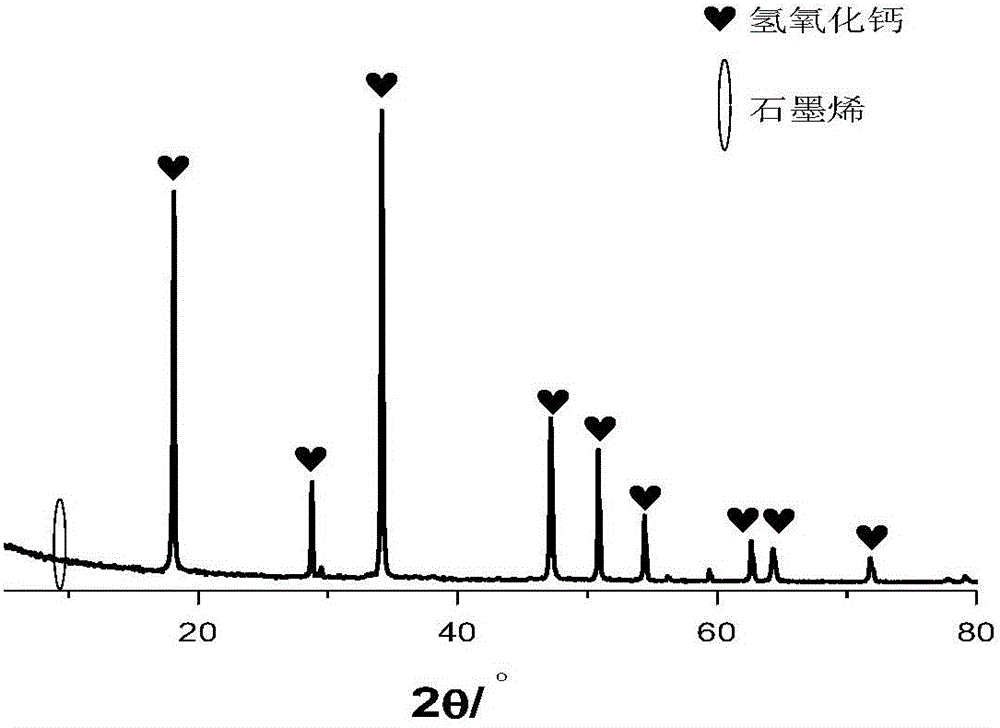

A nano-composite material, calcium hydroxide technology, applied in the field of high-stability calcium hydroxide/graphene nano-composite materials and preparation, can solve problems such as difficult to disperse, not well resolved, and easy agglomeration of nano-calcium hydroxide , to achieve the effect of simple preparation process, strong stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] CaCl with a configured concentration of 0.2mol / L (volume 100ml) 2 Heat on a magnetic stirrer with constant vigorous stirring. When the temperature reaches 90°C, add CaCl at a rate of 4ml / min 2 NaOH solution with a solubility of 0.4mol / L (volume 100ml) was added dropwise into the solution. Continue to keep warm for 20min after the dropwise addition. After the reaction was completed, the solution was naturally cooled to room temperature. Then centrifuge (8000 rpm, 5 minutes), wash with water three times, and then vacuum dry at 110° C. for 24 hours.

[0026] Weigh 20 mg of graphene oxide powder and dissolve in 60 ml of deionized water. Weigh 10 mg of PVP and dissolve in the above deionized water. Weigh 0.5g of nano calcium hydroxide powder and pour it into the above solution. Finally, the above solution was poured into an 80ml polytetrafluoroethylene liner, and finally sealed with a cylinder, and placed in an oven at 100°C for 24 hours. Centrifuge (8000 rpm, 10 minu...

Embodiment 2

[0028] CaCl with a configured concentration of 0.4mol / L (volume 100ml) 2 Heat on a magnetic stirrer with constant vigorous stirring. When the temperature reaches 90°C, add CaCl at a rate of 4ml / min 2 NaOH solution with a solubility of 0.8mol / L (volume 100ml) was added dropwise into the solution. Continue to keep warm for 20min after the dropwise addition. After the reaction was completed, the solution was naturally cooled to room temperature. Then centrifuge (8000 rpm, 5 minutes), wash with water three times, and then vacuum dry at 110° C. for 24 hours.

[0029] Weigh 40 mg graphene oxide powder and dissolve it in 60 ml deionized water. Weigh 20 mg of PVP and dissolve it in the above deionized water. Weigh 1g of nano calcium hydroxide powder and pour it into the above solution. Finally, the above solution was poured into an 80ml polytetrafluoroethylene liner, and finally sealed with a cylinder, and placed in an oven at 120°C for 36h. Centrifuge (8000 rpm, 10 minutes) 3 ...

Embodiment 3

[0031] CaCl with a configured concentration of 0.6mol / L (volume 100ml) 2 Heat on a magnetic stirrer with constant vigorous stirring. When the temperature reaches 90°C, add CaCl at a rate of 4ml / min 2 NaOH solution with a solubility of 1.2mol / L (volume 100ml) was added dropwise into the solution. Continue to keep warm for 40min after the dropwise addition. After the reaction was completed, the solution was naturally cooled to room temperature. Then centrifuge (8000 rpm, 5 minutes), wash with water three times, and then vacuum dry at 110° C. for 24 hours.

[0032] Weigh 60 mg of graphene oxide powder and dissolve in 60 ml of deionized water. Weigh 40mg of PVP and dissolve it in the above deionized water. Weigh 1.5g of nano calcium hydroxide powder and pour it into the above solution. Finally, the above solution was poured into an 80ml polytetrafluoroethylene liner, and finally sealed with a cylinder, and placed in an oven at 140°C for 48 hours. Centrifuge (8000 rpm, 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com