Floating sea water desalination film with backheating capillary action

A capillary action and floating technology, which is applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve the problems that are not suitable for the huge demand for fresh water, the device is inconvenient to carry, and the seawater storage is not large. Offshore production and living needs, improving energy utilization efficiency, and promoting the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

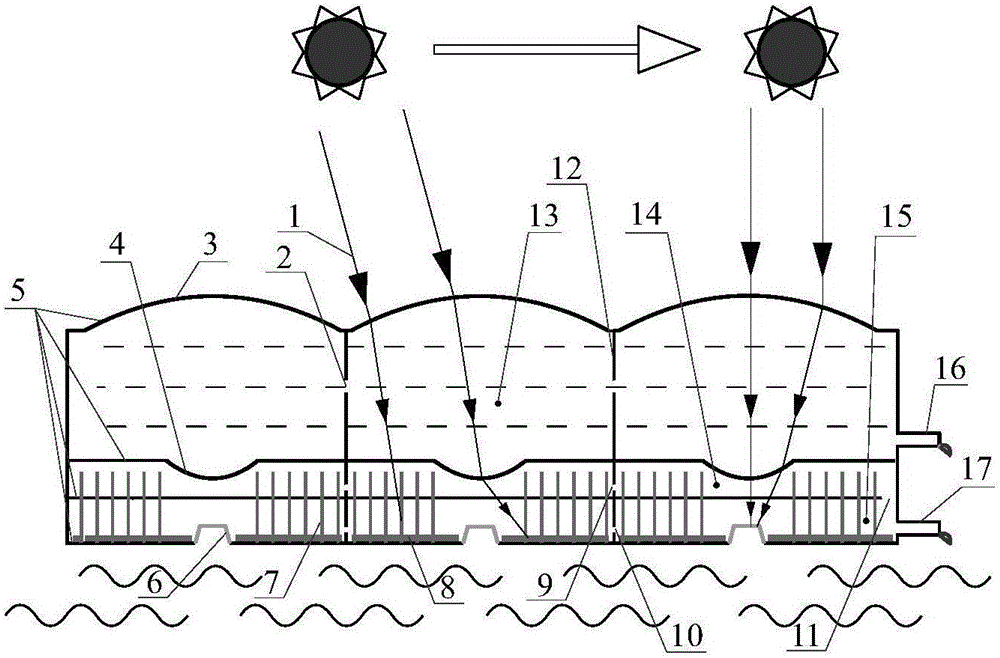

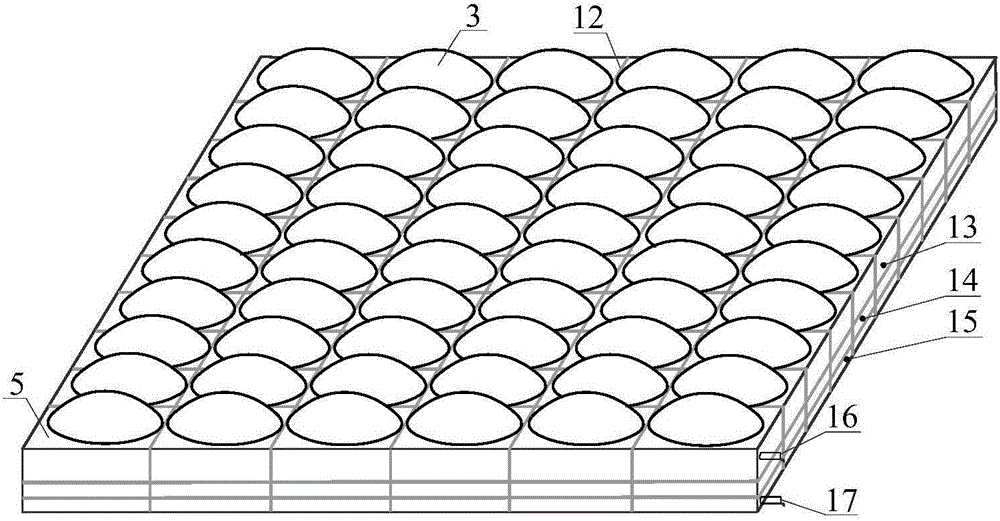

[0030] as attached figure 1 and 2 As shown, the present invention provides a floating seawater desalination membrane device with regenerative capillary action,

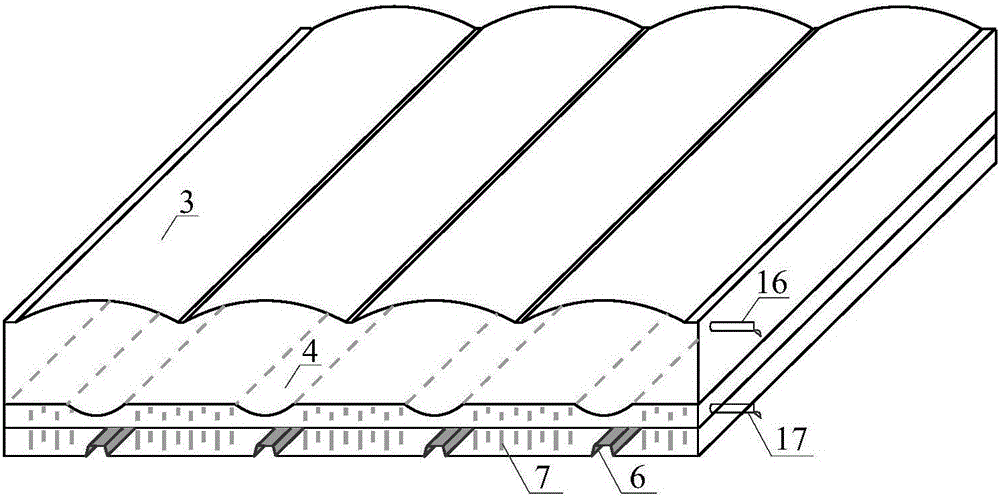

[0031] The device mainly includes a large convex lens 3, a small convex lens 4, a bottom distillation film 6 and a black capillary 7; wherein, the large and small convex lenses are formed by injecting seawater into the upper seawater cavity 13 formed by upper and middle transparent films. The bottom distillation film 6 is only located at the focal spot directly below the lens, and the surrounding part is the bottom transparent film 5 .

[0032] The overall relationship is as follows: four layers of transparent films and vertical diaphragms form three relatively closed chambers at the top, middle and bottom. The bottom distillation film 6 is only located at the focal spot directly below the lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com