Method for inducing wettability changes of super-hydrophobic film through solvent and application

A super-hydrophobic and wettability technology, which is applied in the field of solvent-induced wettability changes of super-hydrophobic films, can solve problems such as unevenness, poor repeatability of deposited film structures, and inability to effectively control the position, and achieve the effect of diverse structures and uniform scales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

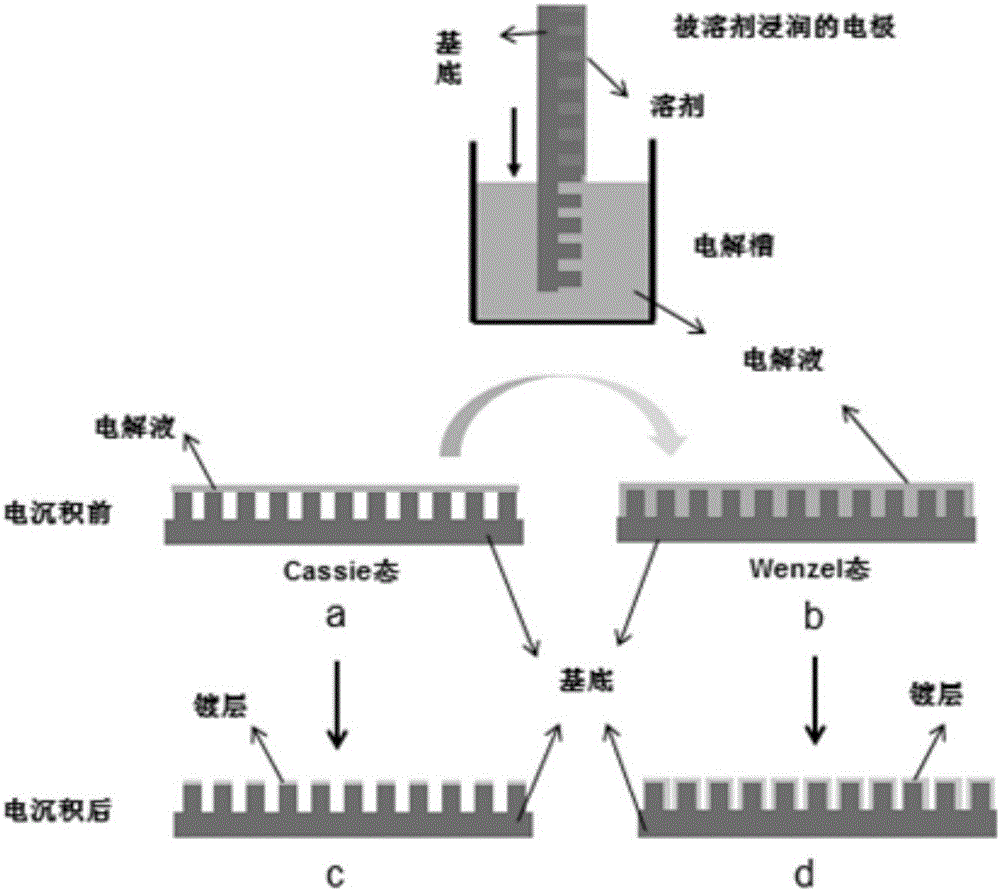

[0027] The micro-nano array structure film is selected to be a zinc oxide nanorod array structure with a rod diameter of 50 nm and a rod length of 0.3 μm. After 2 hours of hydrophobization treatment in a fluorosilane atmosphere, it is taken out to obtain a super-hydrophobic film.

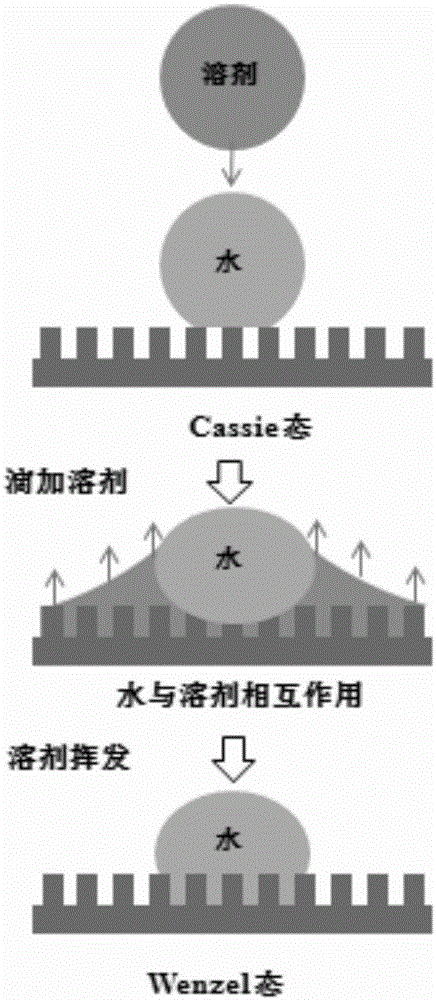

[0028] Such as figure 1 As shown, a 5 μl water droplet is dropped on the superhydrophobic film. At this time, the water droplet presents a superhydrophobic state (CA=155°). After the solvent evaporates naturally, the water droplets assume a hydrophilic state (CA=90°), and the wettability of the film changes by 65° during this process.

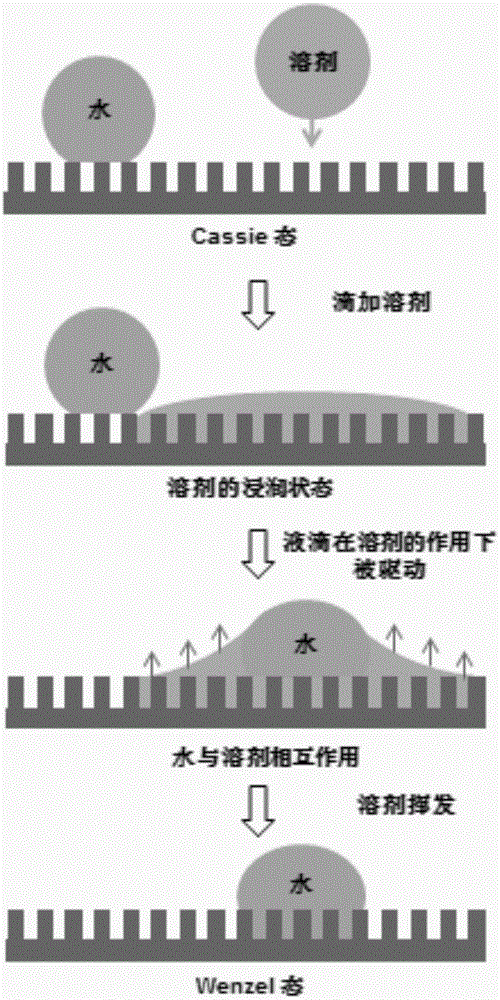

[0029] Such as figure 2 As shown, a 5 μl water droplet is dropped on the superhydrophobic film. At this time, the water droplet presents a superhydrophobic state (CA=155°). , so that after the solvent is naturally volatilized, the water droplet presents a hydrophilic state (CA=78°), and the droplet drive is realized. During this process, the wettability of the fil...

Embodiment 2

[0034] The micro-nano array structure film is selected as a zinc oxide micro-tube array structure. The diameter of the micro-tube is 200 μm, and the tube length is 500 μm. It is taken out after 2 hours of hydrophobization treatment in a fluorosilane atmosphere, and a super-hydrophobic film is obtained.

[0035] Such as figure 1 As shown, a 5 μl water droplet is dropped on the superhydrophobic film. At this time, the water droplet presents a superhydrophobic state (CA=155°). Under normal conditions, after the solvent volatilized naturally, the water droplets showed a hydrophobic state (CA = 136°), and the wettability of the film changed slightly during this process, with a change of 19°.

[0036] Such as figure 2 As shown, drop 5 μl of water droplets on the obtained superhydrophobic film. At this time, the water droplets present a superhydrophobic state (CA=155°). Under this condition, after the solvent evaporates naturally, the water droplet presents a hydrophilic state (CA...

Embodiment 3

[0040] The micro-nano array structure film is selected as a silica nanotube array structure. The diameter of the nanotubes is 200nm and the length of the tube is 1μm. It is taken out after hydrophobization treatment in a fluorosilane atmosphere for 2 hours, and a superhydrophobic film is obtained.

[0041] Such as figure 1 As shown, a 5 μl water droplet is dropped on the superhydrophobic film. At this time, the water droplet presents a superhydrophobic state (CA=155°). , so that after the solvent evaporates naturally, the water droplet assumes a hydrophilic state (CA=88°), and the wettability of the film changes by 67° during this process.

[0042] see figure 2 , drop 5 μl of water droplets on the super-hydrophobic film. At this time, the water droplets are in a superhydrophobic state (CA=155°). After using 6 μl of n-hexane to drop on one side of the water droplets, under the interaction between the water droplets and the solvent, the to-be After the solvent evaporates natu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com