Organic selenium matrix for cultivating selenium-rich agaricus bisporus and preparing method of organic selenium matrix

A technology of Agaricus bisporus and organic selenium, which is applied to mushroom cultivation, preparation of organic fertilizers, botanical equipment and methods, etc., can solve the problems of unfavorable high-efficiency growth of Agaricus bisporus, large fluctuation of product quality, etc., and achieves a remarkable selenium enrichment effect. , improve conversion rate, overcome the effect of unfavorable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Matrix formula

[0019] The main material is composed of 50% (mass ratio, the same below) corn cob and 42% dry cow dung, and the auxiliary materials are 4% wheat bran, 0.3% urea, 1.0% superphosphate, 0.8% lime, 0.5% nitrogen, phosphorus and potassium compound fertilizer (15-15-15), 1.2% gypsum, and the inorganic selenium additive is 0.2% sodium selenite.

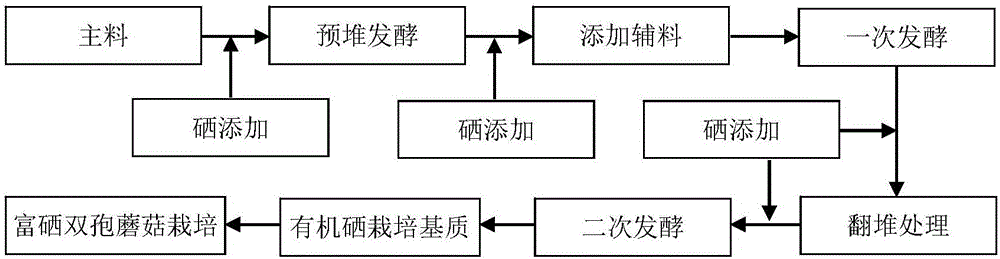

[0020] (2) The preparation of selenium-enriched Agaricus bisporus cultivation organic selenium substrate, the process is as follows figure 1

[0021] 1) Pre-composting fermentation

[0022] Grind the dried cow dung, and evenly adjust the humidity of the cow dung with an aqueous solution of sodium selenite dissolved in 1 / 4 of the total amount, and then continue to adjust the humidity with clean water. Pile it into a strip-shaped material pile with a width of 2.0-2.5m, a height of 1.3-1.5m, and an unlimited length for pre-fermentation for 7 days. At the same time, fully soak the corn cobs with clean water for 7 ...

Embodiment 2

[0033] (1) Matrix formula

[0034] The main material is composed of 48% (mass ratio, the same below) corn cob and 42% dry cow dung, the auxiliary materials are composed of 5% wheat bran, 0.3% urea, 1.2% superphosphate, 1.0% lime, 1.0% gypsum, inorganic selenium The additive is 1.5% sodium selenite.

[0035] (2) Preparation of organic selenium substrate for selenium-enriched Agaricus bisporus cultivation

[0036] 1) Pre-composting fermentation

[0037] Grind the dried cow dung, and evenly adjust the humidity of the cow dung with an aqueous solution of sodium selenite dissolved in 1 / 6 of the total amount, and then continue to adjust the humidity with clean water. Pile it into a strip-shaped material pile with a width of 2.0-2.5m, a height of 1.3-1.5m, and an unlimited length for pre-fermentation for 8 days. At the same time, fully soak the corncobs in clean water for 8 days.

[0038] 2) Primary fermentation

[0039] Pick up corncobs and mix them evenly with pre-fermented co...

Embodiment 3

[0048] (1) Matrix formula

[0049] The main material is composed of 53% (mass ratio, the same below) corn cob and 40% dry cow dung, and the auxiliary materials are 3% wheat bran, 1.4% superphosphate, 1.0% lime, 1.0% nitrogen, phosphorus and potassium compound fertilizer (15-15 -15), composed of 0.3% gypsum, and the inorganic selenium additive is 0.3% sodium selenite.

[0050] (2) Preparation of organic selenium substrate for selenium-enriched Agaricus bisporus cultivation

[0051] 1) Pre-composting fermentation

[0052] Grind the dried cow dung, and evenly adjust the humidity of the cow dung with an aqueous solution of sodium selenite dissolved in 1 / 6 of the total amount, and then continue to adjust the humidity with clean water. Pile it into a strip-shaped material pile with a width of 2.0-2.5m, a height of 1.3-1.5m, and an unlimited length for pre-fermentation for 10 days. At the same time, fully soak the corncobs in clean water for 10 days.

[0053] 2) Primary fermentat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com