Method for preparing dichlorobenzene and trichlorobenzene and increasing para-ortho ratio

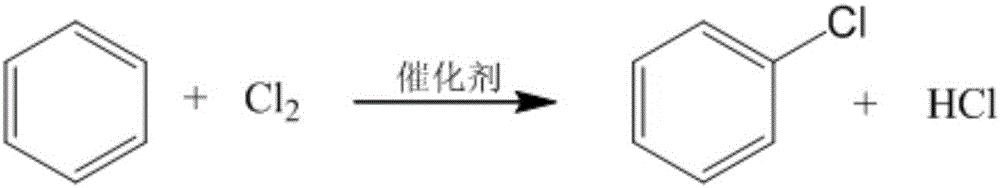

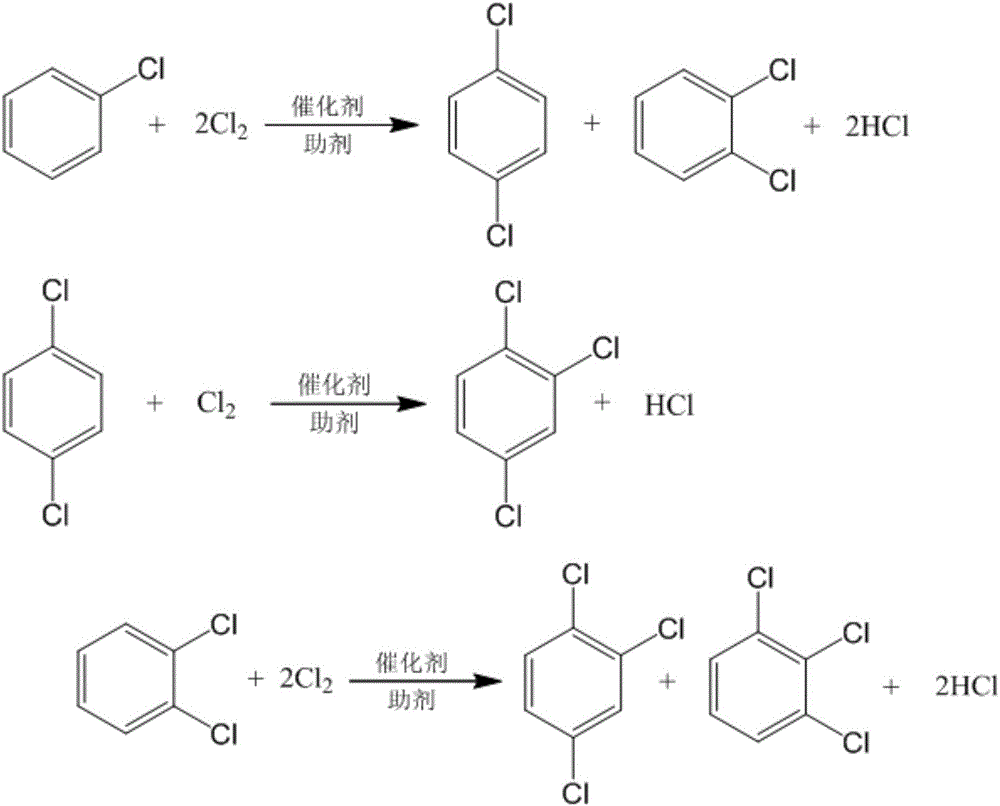

A technology of trichlorobenzene and dichlorobenzene, which is applied in the field of preparing dichlorobenzene and trichlorobenzene to improve the para-ortho ratio, can solve unsatisfactory para-selectivity, low conversion rate and para-selectivity, chlorination Problems such as low para-selectivity of the product, to achieve the effect of low cost of use on an industrial scale, low cost of use, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

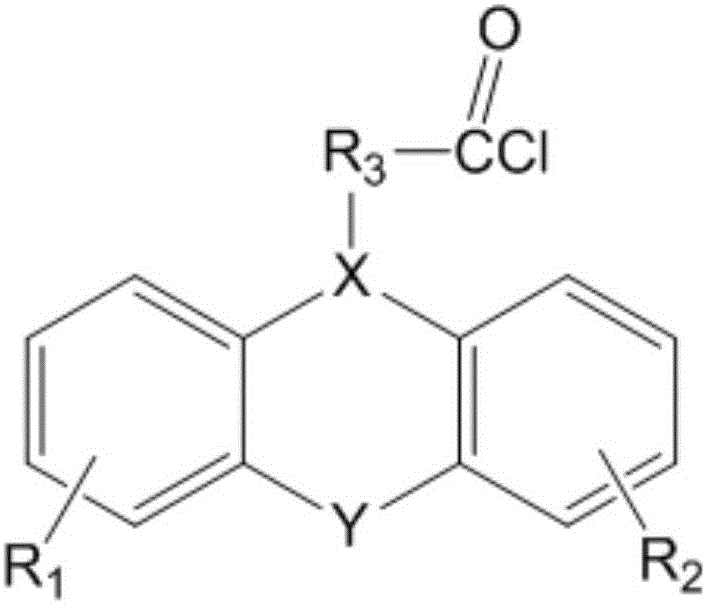

Method used

Image

Examples

Embodiment 1

[0037] The effective reaction volume of the tank reactor is 10L. Enter benzene 10L to reactor by metering pump, wherein add auxiliary agent 0.5wt% in the raw material benzene, add content and be 0.5kg of iron-copper bimetallic catalyst dry base of 60wt% in the system, wherein the weight ratio of iron and copper in the catalyzer is 15:1, control reaction temperature 65~70℃, reaction pressure -0.004MPa, chlorine gas flow rate 0.7m 3 / h, the reaction time is about 6hr. After the reaction is completed, the reaction liquid is delightened, rectified, and crystallized to obtain finished products of dichlorobenzene and trichlorobenzene. The content of p-dichlorobenzene and o-dichlorobenzene is greater than 99.9%, the content of 1,2,4-trichlorobenzene and 1,2,3-trichlorobenzene is greater than 99.5%, and the total yield is 95%.

[0038]

Embodiment 2

[0040] Three kettles are connected in series, and the effective volume of each kettle is 20L, 15L, and 15L respectively, and the total effective volume is 50L. Add 1.5kg of iron-copper bimetallic catalyst dry basis with a content of 60wt% respectively in the first-level, second-level, and third-level kettles, wherein the weight ratio of iron and copper in the catalyst is 15:1, and the reaction temperature is controlled at 65-70°C. The reaction pressure is -0.004Mpa, and the stirring speed is 200rpm. Benzene is fed into the first-stage reaction kettle through a metering pump, wherein 0.5wt% of additives are added to the raw material benzene, the feed flow rate is 8L / hr, and the chlorine gas flow rate of the first-stage, second-stage, and third-stage reactors is 1.5m 3 / h, 1m 3 / h, 1m 3 / h, the reaction solution overflows from the top of the first-stage reactor to the next-stage reactor successively, and the reaction residence time is about 6hr. The reaction solution from the ...

Embodiment 3

[0043] The volume of the ring chlorination reactor is 50L (including catalyst filtration and feed liquid extraction system). Add 2.5kg of iron-copper bimetallic catalyst with a content of 60wt% on a dry basis to the system, wherein the weight ratio of iron to copper in the catalyst is 15:1, control the reaction temperature at 65-70°C, and the reaction pressure -0.004MPa, through a metering pump Benzene is fed into the reactor, wherein 0.5wt% of additives are added to the raw material benzene, the feed flow rate is 8L / hr, and the chlorine gas flow rate is 3.5m 3 / h, the reaction residence time is about 6hr. The HCl generated by the reaction of the chlorination reaction material circulates in the loop reactor, and the reaction liquid containing additives passes through the ceramic filter, and the clear liquid is discharged through the overflow port, and the clear liquid is obtained after light removal, rectification, and crystallization Dichlorobenzene and trichlorobenzene prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com