Preparation method of high-solubility waxy maize starch film

A waxy corn starch, high solubility technology, applied in the field of food packaging films, can solve the problems of increased production cost, low tensile strength, large steric hindrance, etc., and achieves increased production cost, improved mechanical properties, and good heat sealing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a kind of preparation method of highly soluble waxy cornstarch film, and concrete steps are as follows:

[0032] (1) Evenly disperse 1.00 g of waxy cornstarch in 99 mL of distilled water, stir in a boiling water bath to pregelatinize, then cook at 121°C for 20 minutes until completely gelatinized, and then cool to room temperature.

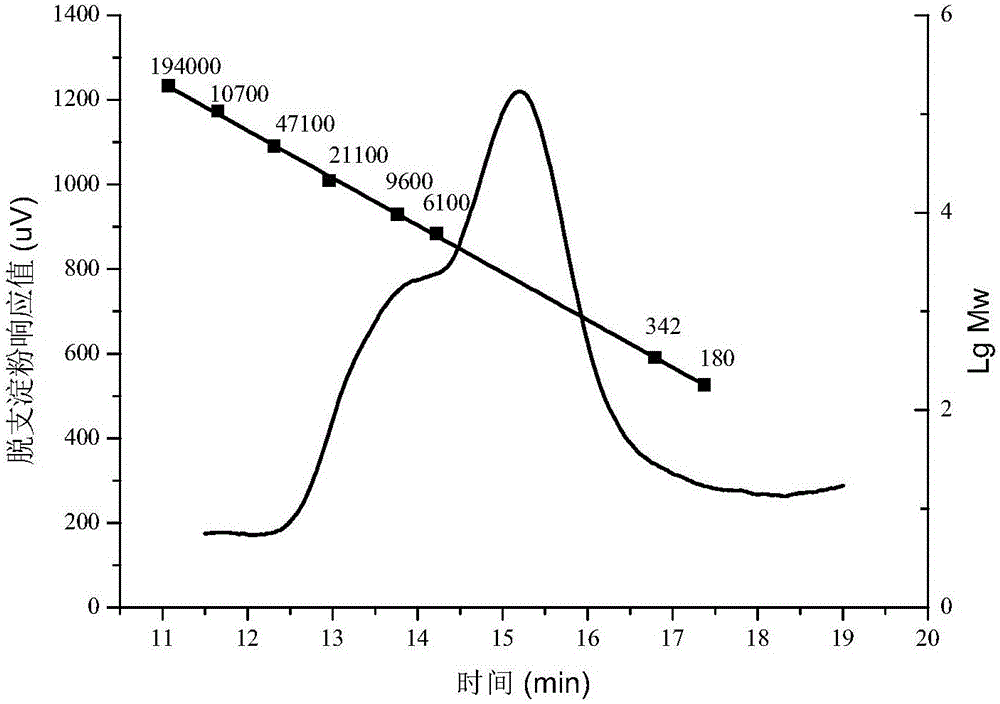

[0033] (2) Add 7.5U / g starch isoamylase to the waxy cornstarch after gelatinization for debranching, the reaction temperature is 40°C, and the reaction time is 12h; after complete debranching, the solution that completes the hydrolysis reaction is placed in Boil in a boiling water bath for 10 minutes to inactivate the enzyme, centrifuge at 5000 rpm for 10 minutes to remove the enzyme, and after rotary evaporation at 80°C, freeze-dry to form an amorphous powder to obtain DWMS.

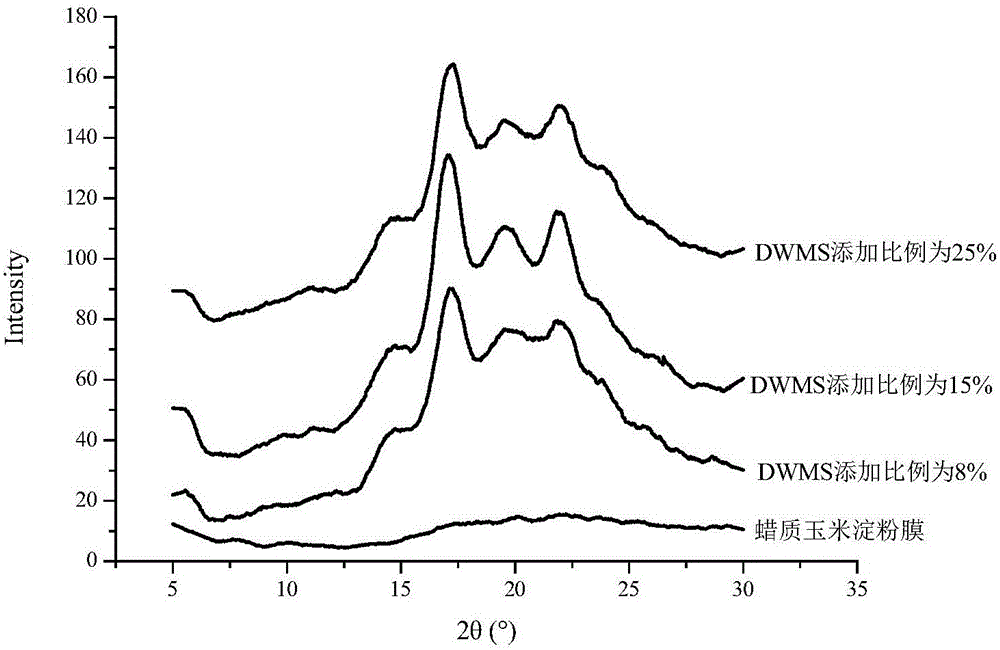

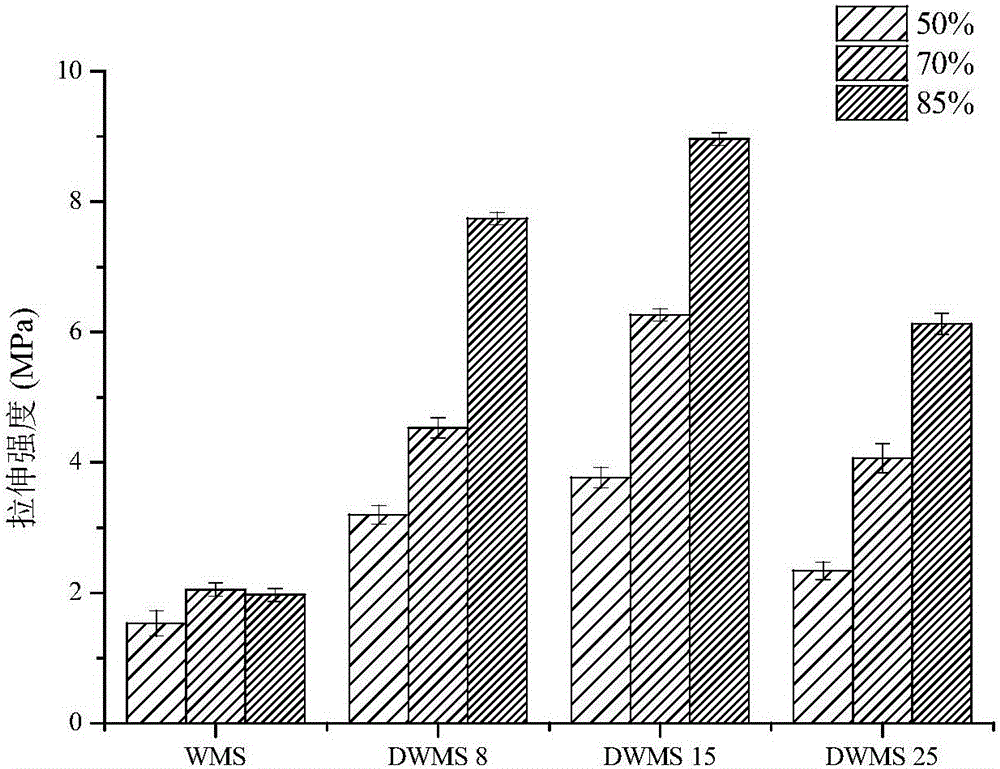

[0034] (3) Mix DWMS with waxy cornstarch, the mixing ratios are 0:100, 8:92, 15:85, 25:75 respectively, prepare a suspension with a concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com