A kind of clear water anti-seepage glue and its preparation method and application

An anti-seepage glue and water technology, applied in the field of anti-seepage glue, can solve the problems of waste of manpower and material resources, poor mechanical properties, poor extensibility, etc., and achieve the effects of small specific gravity, high adaptability to deformation, and strong extensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

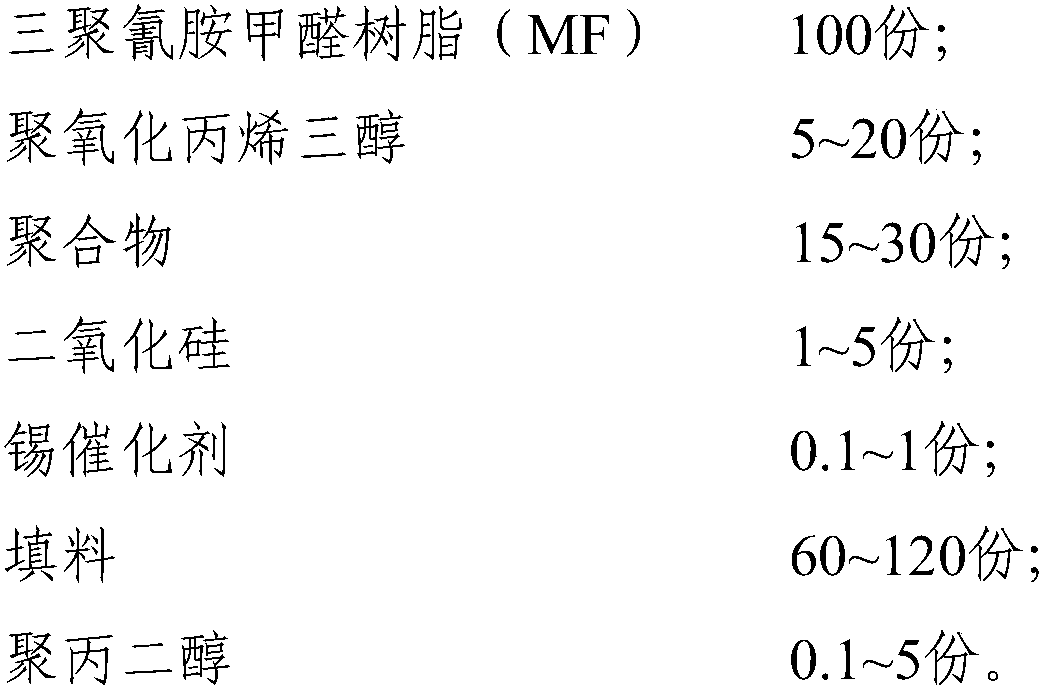

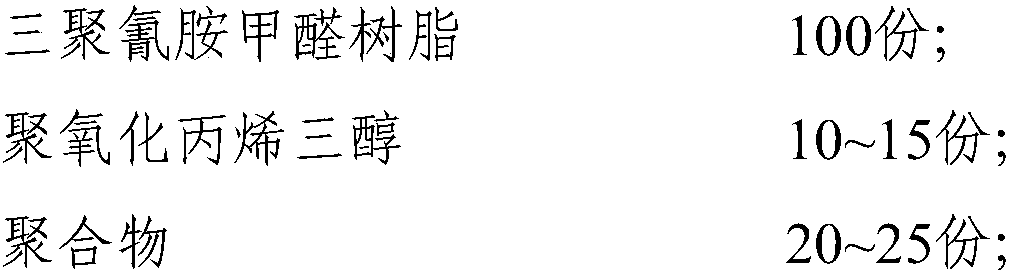

[0033] 1. Composition

[0034]

[0035] 2. Preparation method:

[0036] Add melamine formaldehyde resin, polyoxypropylene triol, silicon dioxide, tin catalyst, and polypropylene glycol into the reactor to preheat at 50°C, and add the polymer in three batches at a ratio of 1-3:1-3:1-3 In the reactor, react at 70°C for 1.5 hours, add filler and stir evenly to obtain the anti-seepage glue.

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the TDI is replaced by MDI.

Embodiment 3

[0040] The difference between this example and Example 1 is that the kaolin is replaced by a mixture of quartz powder and talcum powder, and the ratio of the two is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com