Low-temperature-resistant super-tough polyamide material

A low temperature resistant and super tough technology, applied in the field of polymer materials, can solve the problems of poor performance, unsatisfactory low temperature toughness of PA66, unstable dimensions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Low temperature resistant super tough nylon material, its raw material components include: PA66: 97kg, additives: 2kg, antioxidant: 0.5kg, lubricant: 0.1kg, coupling agent: 0.2kg. among them:

[0016] PA66 is a commercially available product with a material viscosity of 2.2~2.4dL / g and a melt index of 18~20g / 10min (the same below).

[0017] The auxiliary agent is: compatibilizer 493.

[0018] Antioxidant: H3336.

[0019] The lubricant is: TAF.

[0020] The coupling agent is: KH~550.

[0021] The preparation method adopts the conventional extrusion preparation method. In this embodiment, the preparation method is:

[0022] Dry PA66 at 100℃ for at least 4 hours with air blowing to make the moisture content not higher than 2%, then add the remaining components and mix well in the high-speed mixer model, and extrude the uniformly mixed materials in the twin-screw extruder Granulation.

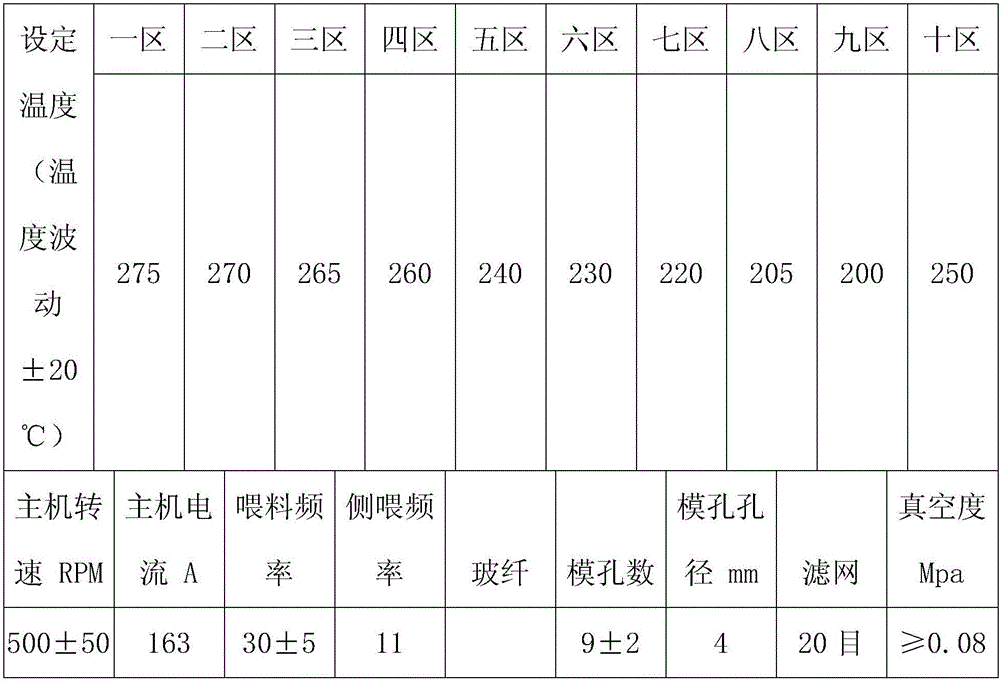

[0023] Extruder setting parameters are shown in Table 1:

[0024] Table 1:

[0025]

[0026] The dif...

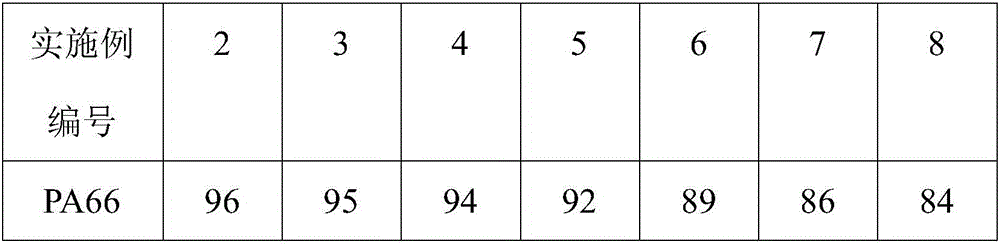

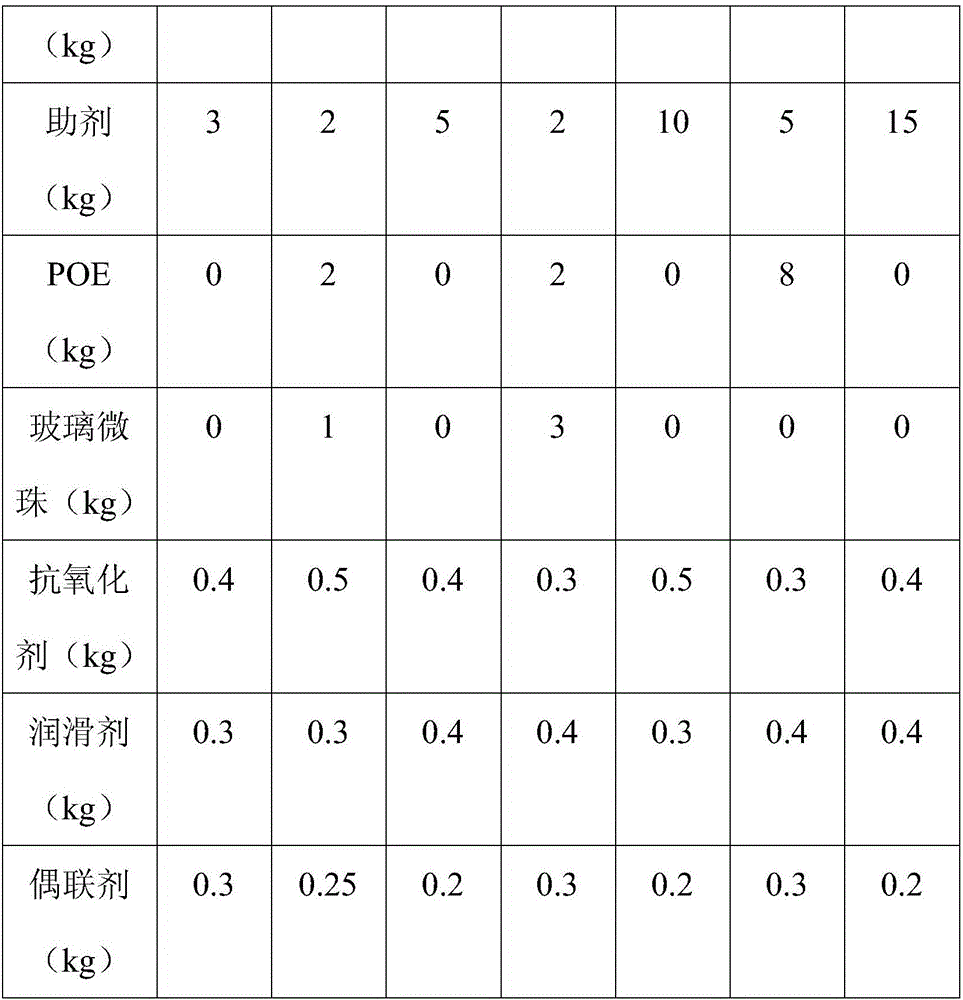

Embodiment 2

[0032] The auxiliary agent is: compatibilizer 493.

[0033] Antioxidant: Antioxidant 1010.

[0034] Lubricant: EBS.

[0035] The coupling agent is: A~1100.

Embodiment 3 and Embodiment 7

[0037] The auxiliary agent is: compatibilizer 493.

[0038] Antioxidant: Antioxidant 1076.

[0039] The lubricant is: silicone powder.

[0040] The coupling agent is: KH540.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com