Silicone rubber/polylactic acid thermoplastic vulcanized rubber and preparation method thereof

A thermoplastic vulcanizate and silicone rubber technology, applied in the field of silicone rubber/polylactic acid thermoplastic vulcanizate, can solve the problems of macroscopic phase separation, poor compatibility, difficult blending, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

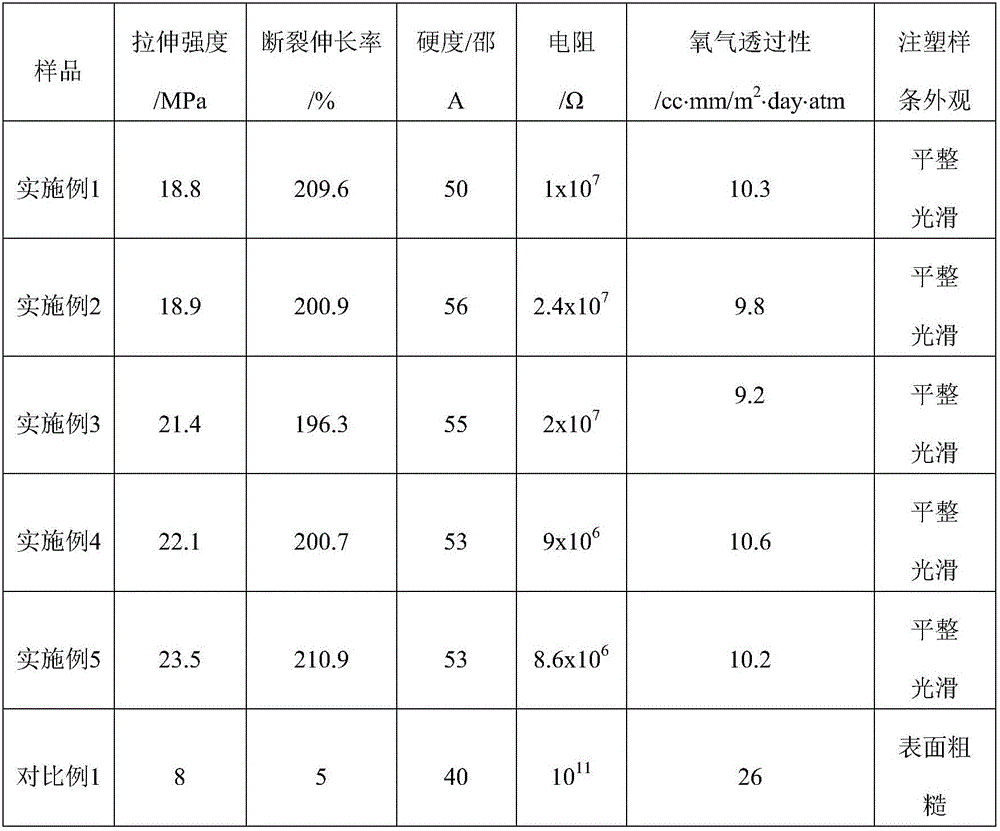

Embodiment 1

[0049] First, graphene oxide was prepared by ultrasonic-assisted Hummer's method, and then 1 g of graphene oxide and 2 g of triaminopropyl triethoxysilane were mixed in ethanol solution, the pH value was adjusted to 5, and the functionalized graphite oxide was prepared by stirring for 24 hours. 100 parts by weight of SR were put into the open mill at room temperature, plasticized, 2 parts by weight of antioxidant were added, and the mixing was continued to prepare a silicone rubber masterbatch Then, melt 68 parts by weight of PLA in an internal mixer at 160°C, add silicone rubber masterbatch, 3 parts by weight of triaminopropyl triethoxysilane, and 1.5 parts by weight of auxiliary crosslinking agent, and uniformly mix to obtain Simple blended rubber-plastic blend; add simple blended rubber-plastic blend and pre-mixed together 0.1 parts by weight of functionalized graphene oxide and 1.5 parts by weight of a Dibenzoyl oxide was dynamically vulcanized for 6 minutes to obtain a dy...

Embodiment 2

[0051] Formulation composition and consumption, technological condition and technological process are with embodiment 1, and the difference is that the consumption of functionalized graphene oxide and dibenzoyl peroxide is respectively 0.3 weight part and 1.5 weight part, the performance test of gained SR / PLA TPV The results are shown in Table 1.

Embodiment 3

[0053] Formulation composition and consumption, technological condition and technological process are with embodiment 1, and the difference is that the consumption of functionalized graphene oxide and dibenzoyl peroxide is respectively 0.3 parts by weight and 1.0 parts by weight, the performance test of gained SR / PLA TPV The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com