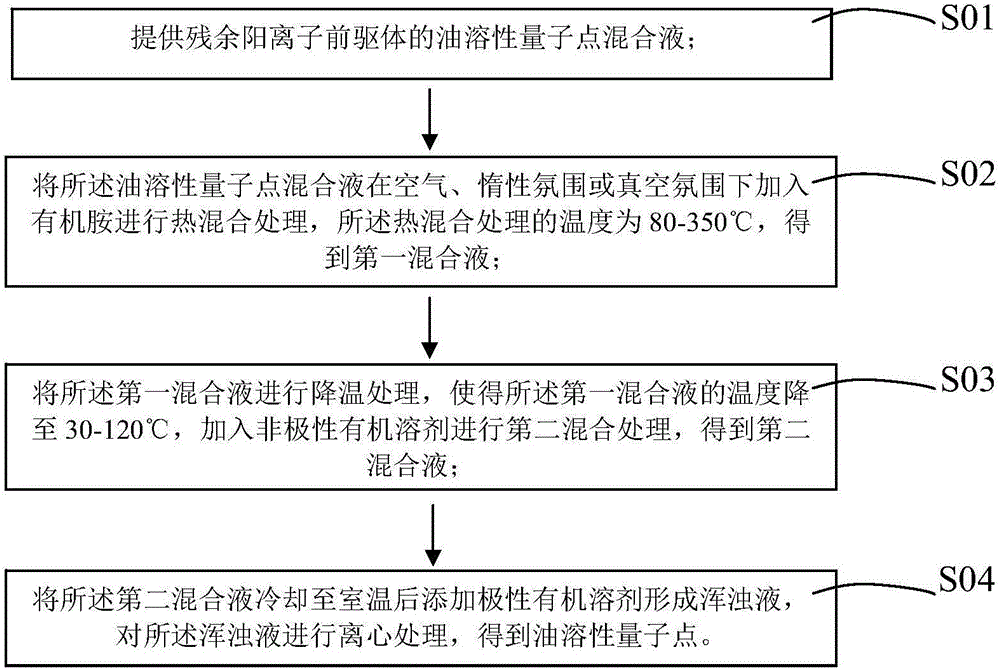

Method for removing residual cationic precursors from oil-soluble quantum dots

A quantum dot and oil-soluble technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems affecting the purity of quantum dot solutions, the luminous efficiency and life of QLED devices, etc., to improve reproducibility, easy to repeat, and reproducible good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

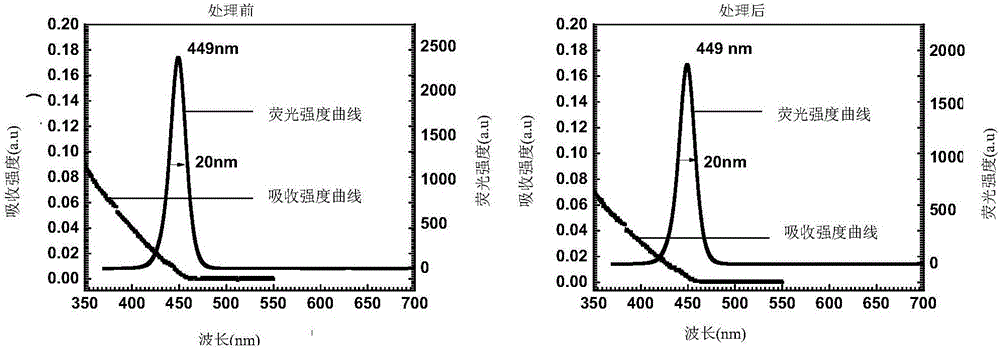

[0038] A Cd that removes blue luminescence x Zn 1-x The method for residual cationic precursor in S / ZnS oil-soluble quantum dots, comprises the following steps:

[0039] S11. Under the protection of Ar gas, take 20ml of Cd x Zn 1-x S / ZnS quantum dots (0.05mg / ml) n-hexane solution was injected into a three-necked flask containing 3ml of oleic acid (OA) and 3ml of octadecene (ODE) to obtain blue oil-soluble quantum dots with residual cationic precursors mixed solution;

[0040] S12. Heat the blue oil-soluble quantum dot mixture in the three-necked flask to 80°C and maintain it for 20 minutes, then raise the temperature to 180°C to make the blue oil-soluble quantum dot mixture become a clear liquid and maintain it for 30 minutes , then drop the temperature of the blue oil-soluble quantum dot mixture to 150° C. and then add oleylamine to obtain the first mixture, wherein the amount of oleylamine added satisfies: the molar ratio of the cationic precursor to the oleylamine 1:2;...

Embodiment 2

[0045] A Cd that removes red or green luminescence 1-x Zn x Se 1-y S y A method for residual cationic precursors in oil-soluble quantum dots, comprising the following steps:

[0046] S21. Under the protection of Ar gas, take 20ml of Cd 1-x Zn x Se 1-y S y Quantum dots (0.05mg / ml) n-hexane solution was injected into a three-necked flask containing 3ml of oleic acid (OA) and 3ml of octadecene (ODE), to obtain a blue oil-soluble quantum dot mixed solution of residual cation precursor;

[0047] S22. Heating the red or green luminescent oil-soluble quantum dot mixture in the three-necked flask to 80°C and maintaining it for 20 minutes, then raising the temperature to 180°C to make the red or green oil-soluble quantum dot mixture become a clear and transparent liquid and Maintain for 30 minutes, then lower the temperature of the red or green oil-soluble quantum dot mixture to 150°C and then add oleylamine to obtain the first mixture, wherein the amount of oleylamine added sat...

Embodiment 3

[0051] A method for directly removing residual cationic precursors in the reaction system to obtain high-purity oil-soluble quantum dots. This example is suitable for the system of using oleic acid and octadecene as reaction solvents to synthesize quantum dots. For the synthesis of quantum dots, refer to Chemistry of Materials 2008,20,5307-5313, its synthesis comprises the following steps:

[0052] S311. Preparation of zinc oleate and cadmium oleate mixture: 9 mmol of zinc acetate, 1 mmol of cadmium oxide, 8 mL of oleic acid, and 15 mL of octadecene were placed in a 50 mL three-necked flask. Degas at room temperature, heat up to 120°C for 20mins, pass argon and heat up to 120°C for 10mins, and finally heat the mixture to 250°C until a clear, transparent solution is formed.

[0053] S312. Preparation of S-ODE: 1.8 mmol of S was added to 3 ml of octadecene, heated to 230°C until a clear and transparent solution was formed, and then kept at 140°C.

[0054] S313. Preparation of S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com