Quenching device for support roller path part of oversized excavator and quenching process

A technology for supporting raceways and quenching devices, which is applied in the field of metal quenching, and can solve problems such as poor hardness uniformity, high energy consumption, and shallow hardened layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

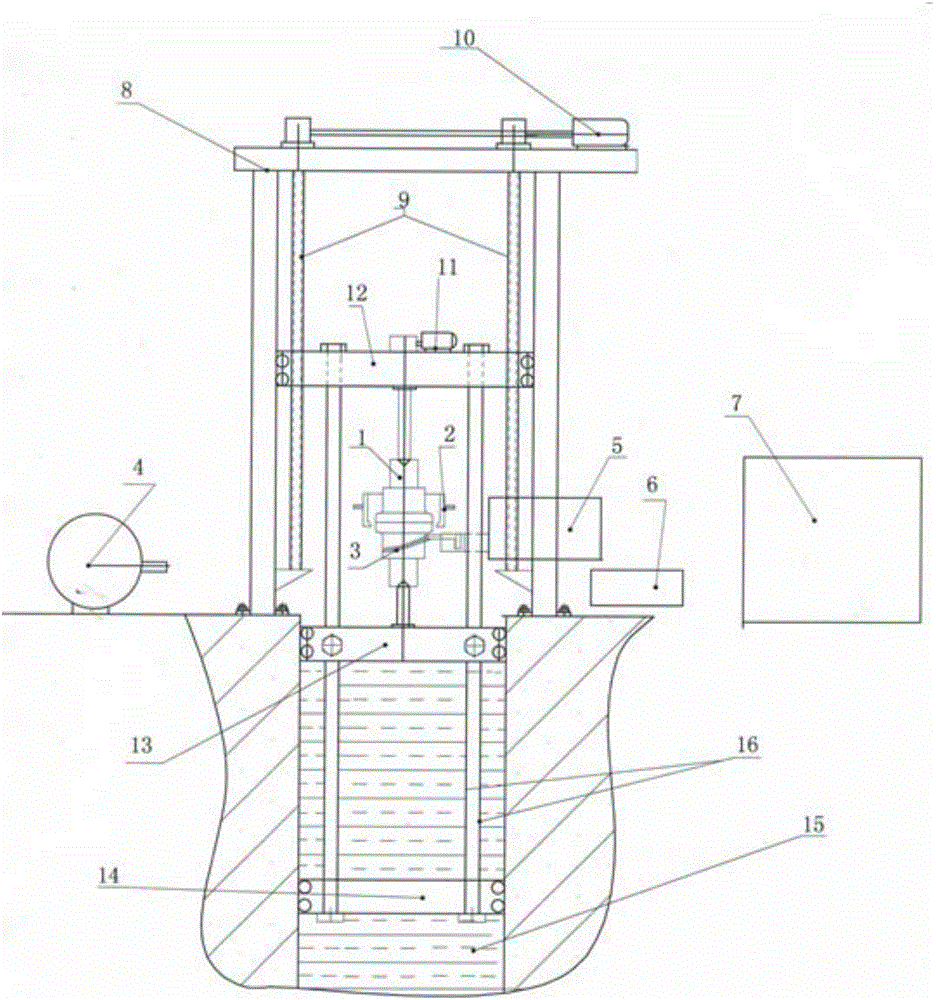

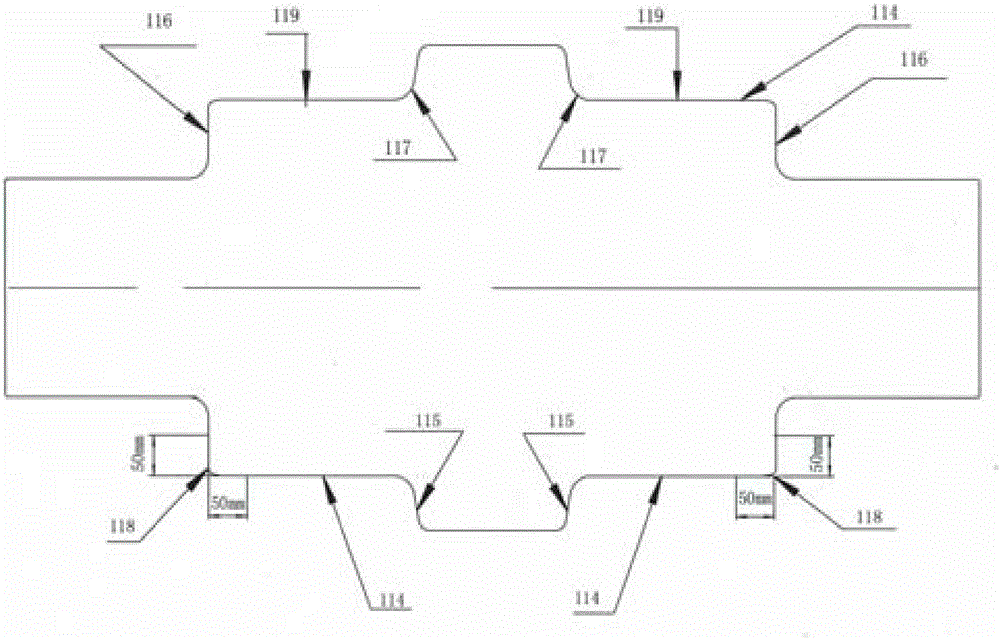

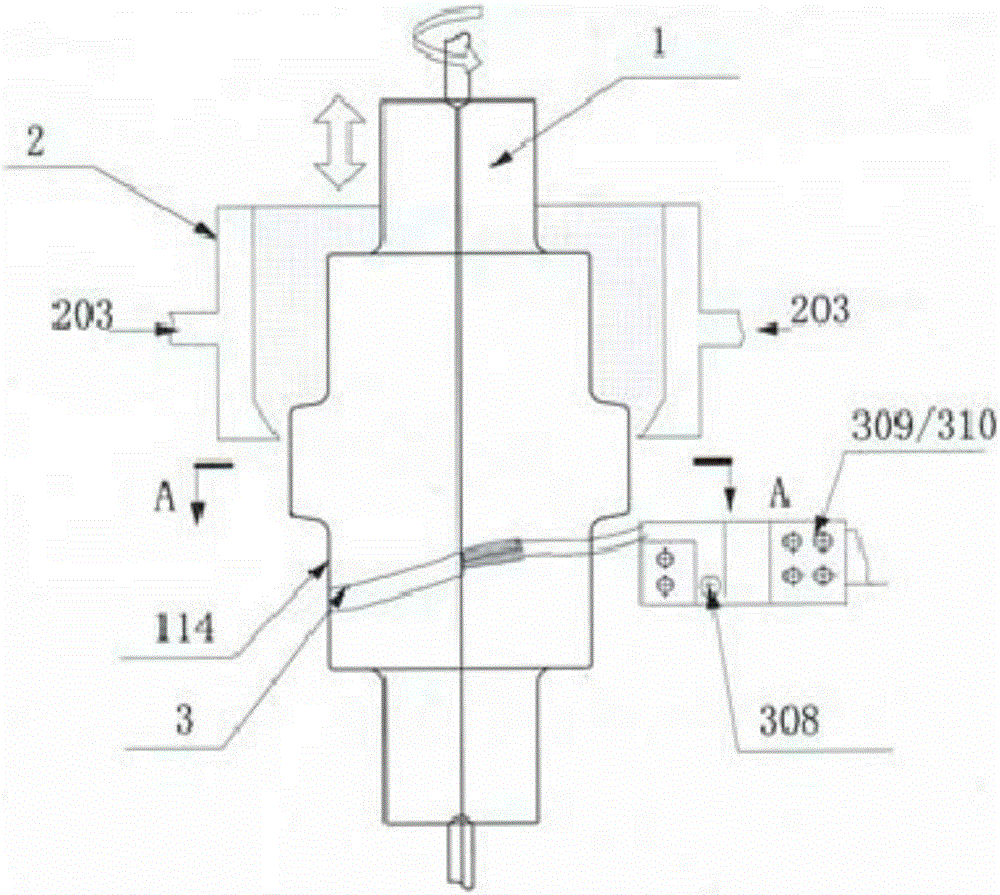

[0075] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0076] see Figure 1 to Figure 11 .

[0077] The embodiment of the quenching device and its process for the supporting raceway of an extra-large excavator is aimed at the Terex / O&KRH170 track roller, and is also suitable for other large crawler excavator rollers.

[0078] The present invention is a quenching device for the support raceway of an extra-large excavator, comprising a vertical induction hardening machine tool, a support roller support raceway quenching water spray quenching device 2, a support roller support raceway induction quenching heating tool 3, The supporting roller support raceway induction quenching heating tool 3 is located at the corresponding processing part of the workpiece in the induction hardening machine tool, and cooperates with it. the upper part.

[0079] Described vertical induction hardening lathe comprises t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com