Plunger pump driven by piezoelectric chip vibrators

A piezoelectric wafer and piezoelectric vibrator technology, applied in the field of plunger pumps, can solve the problems of damage, low reliability, low output flow and pressure, etc., and achieve the effects of high reliability, low cost, and improved output pressure and flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

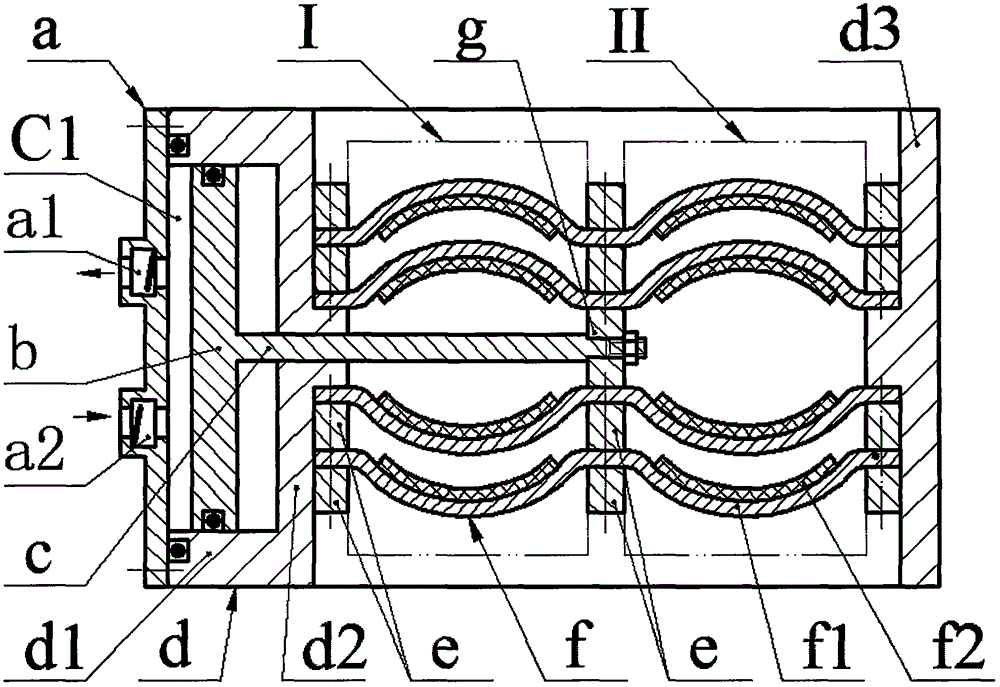

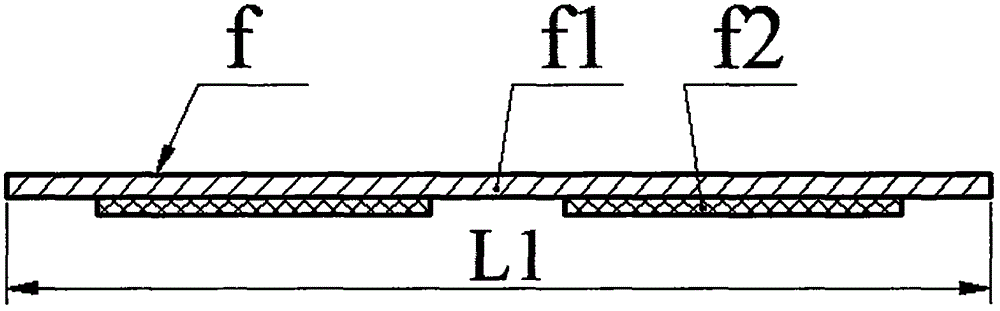

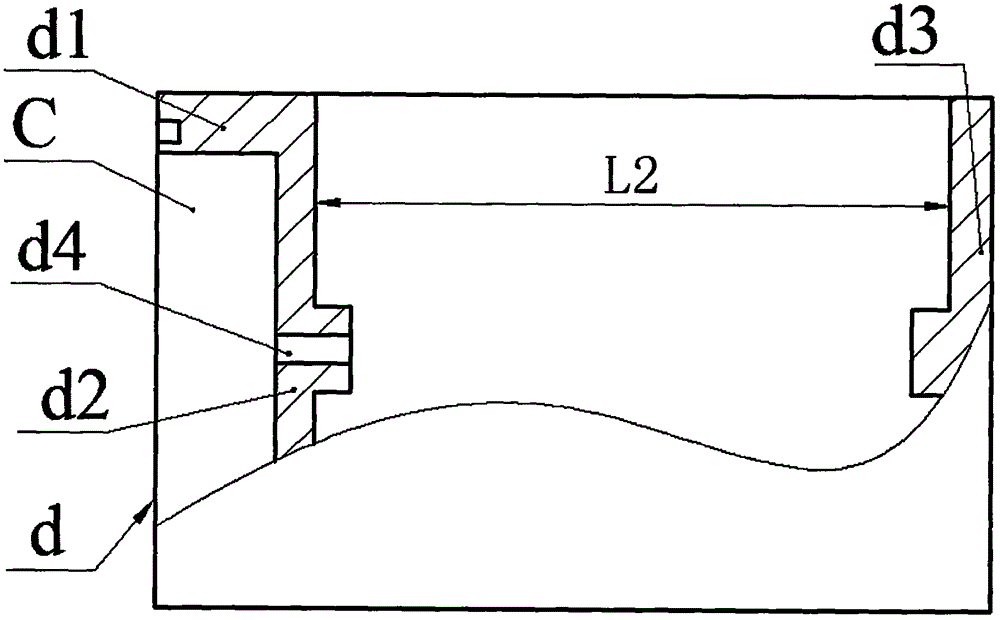

[0010] The main body d is provided with a left wall plate d2 and a right wall plate d3, and the left wall plate d2 is provided with a guide hole d4 and a cavity C which communicate with each other, and the end of the side wall d1 of the cavity C is installed with a pump cover a , the pump cover a is provided with an inlet valve a2 and an outlet valve a1; a piston b is installed in the cavity C, and the piston b forms a pump cavity C1 with the side wall d1 of the cavity C and the pump cover a; the piston rod c on the piston b passes through The guide hole d4 protrudes, the end of the piston rod c is fixed with a connecting block g through a nut, and two sets of piezoelectric vibrators f are installed on the connecting block g through a pressing block e and screws. e and screws are respectively fixed on the left wall plate d2 and the right wall plate d3, the piezoelectric vibrator f is formed by bonding the metal substrate f1 and the piezoelectric chip f2; the piezoelectric vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com