Boiler system adopting electromagnetic induction type heating mode and implementation method thereof

A realization method, an inductive technology, applied in the field of high-pressure boilers, can solve the problems of low energy conversion rate, slow heating speed, high manufacturing cost, etc., and achieve the effects of high safety, fast heating speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

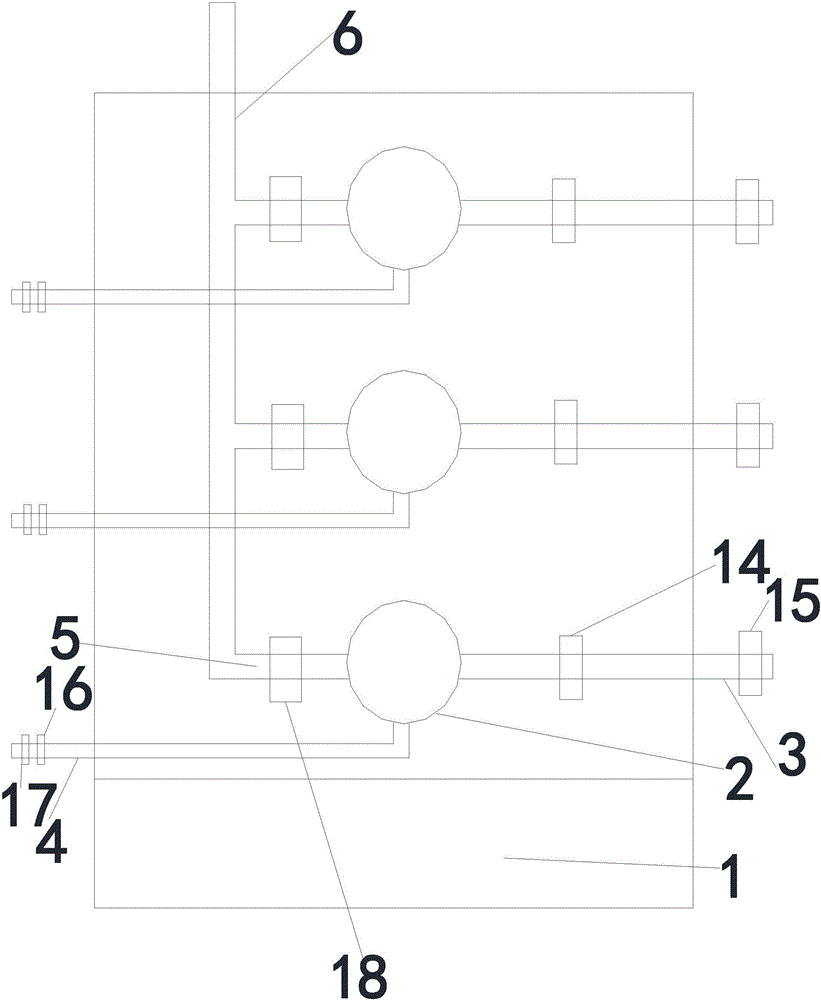

[0043] Such as Figure 1~2 As shown, an electromagnetic induction heating boiler system includes a control room, a controller is arranged in the control room, and several electromagnetic induction heating boilers are arranged in the heating room, and each boiler is equipped with a water inlet pipe, a sewage pipe and an air outlet pipe. Sub-pipes, the outlet sub-pipes are collected on the outlet main pipe.

[0044] The boiler in this embodiment includes a furnace cylinder, an insulation layer is arranged inside the furnace cylinder wall, an electromagnetic induction heating coil is provided at the middle and lower part of the furnace cylinder wall, the heating coil is connected to a power supply, and a water inlet pipe and a sewage discharge pipe are provided on the lower side of the furnace cylinder , There is an outlet pipe on the upper side of the furnace drum, and a liquid level gauge is installed on the side of the furnace drum.

[0045] In this embodiment, the water inle...

Embodiment 2

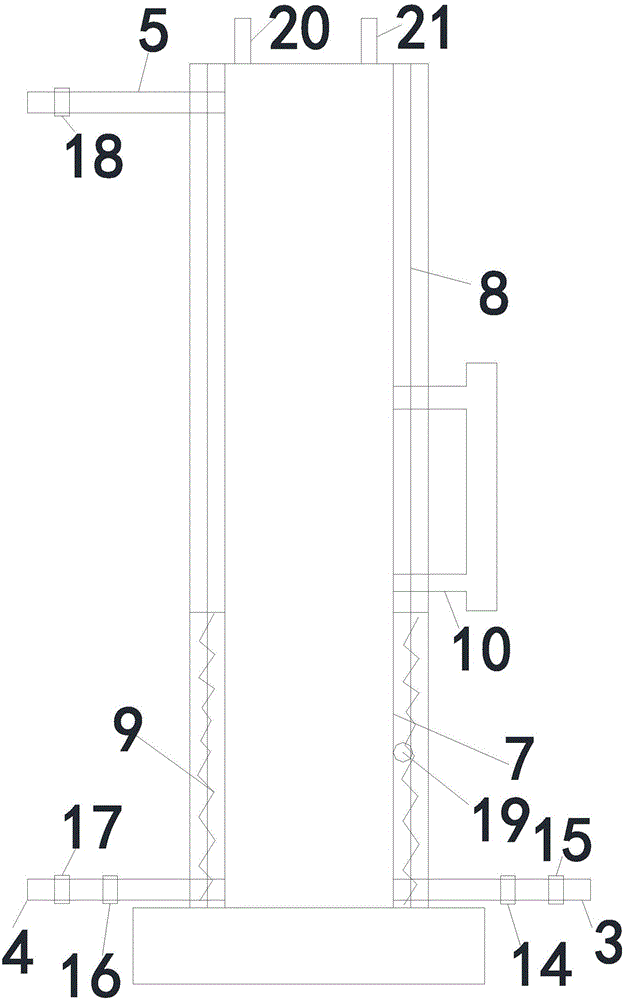

[0054] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the boiler in this embodiment includes a furnace cylinder, an insulation layer is arranged inside the furnace cylinder wall, and an electronic induction heating coil is arranged at the middle and lower part of the furnace cylinder wall, and the heating coil is connected with the furnace cylinder wall. The power supply is connected, the lower side of the furnace drum is provided with a water inlet pipe and the sewage pipe, the upper side of the furnace drum is provided with an outlet pipe, and the top of the furnace drum is provided with an electrode rod liquid level gauge.

Embodiment 3

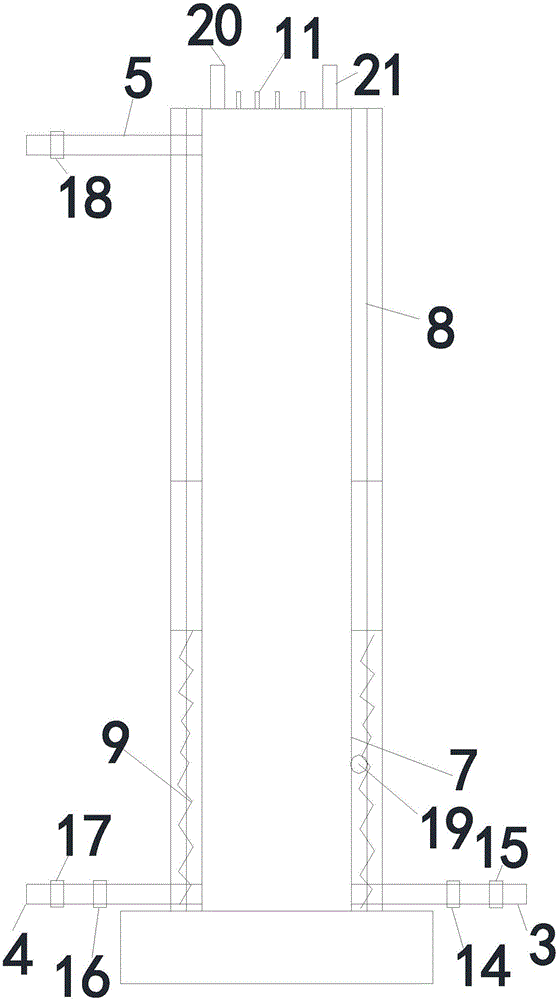

[0056] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the boiler in this embodiment includes a U-shaped furnace tube, an insulation layer is provided outside the furnace tube wall, and an electronic induction type is provided at the middle and lower part of the vertical part of the furnace tube wall. The heating coil, the water inlet pipe and the sewage pipe are arranged at the lateral part of the furnace wall, the gas outlet pipe is arranged on the upper side of the furnace cylinder, and the electrode rod liquid level gauge is arranged on the top of the furnace cylinder.

[0057] The electronic induction heating coil in this embodiment is arranged between the inner insulation layer and the outer insulation layer; the inner insulation layer includes two layers of heat insulation layers, and the outer insulation layer includes three layers of heat insulation layers. Gel insulation.

[0058] In this embodiment, a temperature sensor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com