Power cable

A power cable and conductive layer technology, applied in the field of power cables, can solve the problems of destruction or destruction of underground animals such as mice, sheath cable core detachment, poor cable protection, etc., to achieve light weight, prevent mechanical damage, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

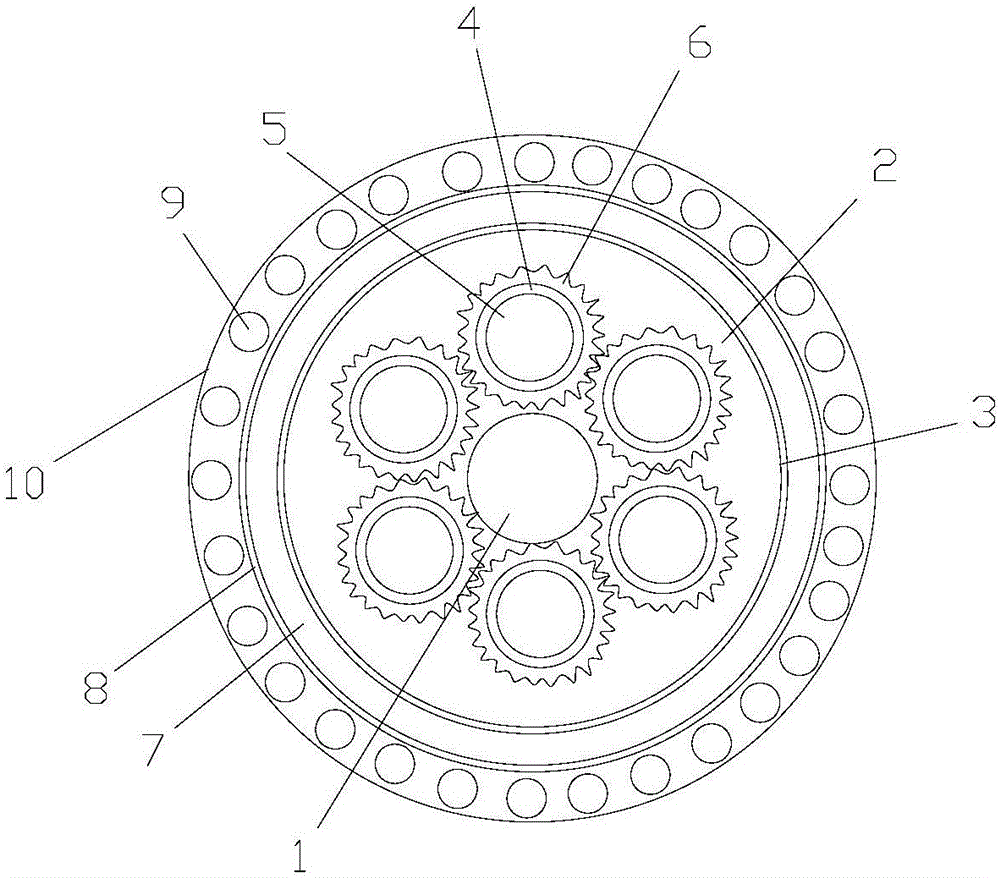

[0021] Referring to 1, a power cable includes a supporting core 1, a single core body 2 and an insulating layer 3, the supporting core 1 and the single core body 2 are located in the insulating layer 3, and the supporting core 1 is located in the insulating layer 3 The center position of the single core body 2 is provided with more than one, and the single core body 2 is circumferentially arranged in layers in the annular cavity formed by the support core 1 and the insulating layer 3, and the single core body 2 includes a hollow The conductive layer 4, the insulating medium filler 5 and the insulating medium protective cover 6, the insulating medium filler 5 is arranged in the hollow conductive layer 4, and the hollow conductive layer 4 is set in the insulating medium protective cover 6; The periphery of the insulating medium protective cover 6 is provided with wrinkled textures, the insulating layer 3 is provided with an inner sheath 7, and the inner sheath 9 is provided with ...

Embodiment 2

[0029] Referring to 1, a power cable includes a supporting core 1, a single core body 2 and an insulating layer 3, the supporting core 1 and the single core body 2 are located in the insulating layer 3, and the supporting core 1 is located in the insulating layer 3 The center position of the single core body 2 is provided with more than one, and the single core body 2 is circumferentially arranged in layers in the annular cavity formed by the support core 1 and the insulating layer 3, and the single core body 2 includes a hollow The conductive layer 4, the insulating medium filler 5 and the insulating medium protective cover 6, the insulating medium filler 5 is arranged in the hollow conductive layer 4, and the hollow conductive layer 4 is set in the insulating medium protective cover 6; The periphery of the insulating medium protective cover 6 is provided with wrinkled textures, the insulating layer 3 is provided with an inner sheath 7, and the inner sheath 9 is provided with ...

Embodiment 3

[0037] Referring to 1, a power cable includes a supporting core 1, a single core body 2 and an insulating layer 3, the supporting core 1 and the single core body 2 are located in the insulating layer 3, and the supporting core 1 is located in the insulating layer 3 The center position of the single core body 2 is provided with more than one, and the single core body 2 is circumferentially arranged in layers in the annular cavity formed by the support core 1 and the insulating layer 3, and the single core body 2 includes a hollow The conductive layer 4, the insulating medium filler 5 and the insulating medium protective cover 6, the insulating medium filler 5 is arranged in the hollow conductive layer 4, and the hollow conductive layer 4 is set in the insulating medium protective cover 6; The periphery of the insulating medium protective cover 6 is provided with wrinkled textures, the insulating layer 3 is provided with an inner sheath 7, and the inner sheath 9 is provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com