High-power LED lighting package structure for vehicle lamp

A technology of LED lighting and packaging structure, applied in signal devices, vehicle parts, transportation and packaging, etc., can solve the problems of high cost, low thermal conductivity of alumina, burnout, etc., to achieve high integration requirements, low system thermal resistance, Effect of high drive current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

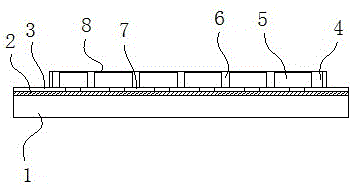

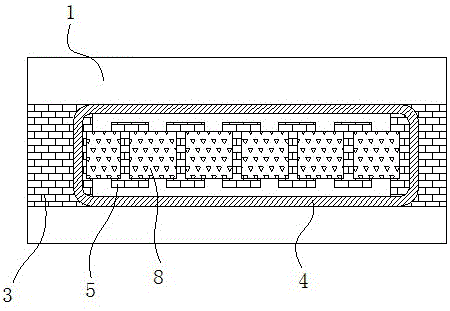

[0016] Such as figure 1 and figure 2 As shown, the high-power LED lighting packaging structure for car lights is mainly used in car lights. The main structural components include: high-purity aluminum plate 1, diamond-like coating 2, conductive layer 3, white silica gel 4, LED chip 5, packaging layer 6, liquid phase fusion 7 and fluorescent film 8; Diamond-like coating 2, a conductive layer 3 is set on the diamond-like coating 2, a liquid phase fusion 7 is set on the conductive layer 3, LED chips 5 are set on the liquid phase fusion 7, and an encapsulation layer 6 is set between the LED chips 5, The outer periphery is encapsulated with white silica gel 4; a fluorescent adhesive film 8 is arranged on the LED chip 5.

[0017] High-purity aluminum plate 1 adopts thin film evaporation deposition and ion implantation technology to obtain diamond-like coating 2 (diamond-like fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com