Composite nano material as well as preparation method and application thereof

A technology of composite nanomaterials and composite materials, which is applied in the field of nanomaterial applications, can solve problems such as high cost and complicated preparation procedures, and achieve the effects of short cycle, simple process and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

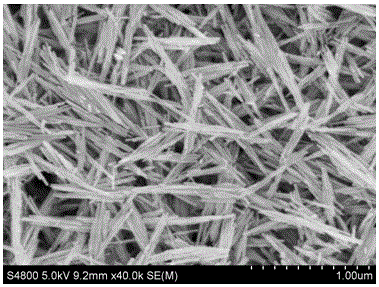

[0024] A composite nanomaterial, composed of carbon nitride and 85wt% carbon nanofibers accounting for 15wt% of the composite material, the composite nanomaterial is in the form of a fiber, the diameter of the fiber is 10 nm, and the length is 600 nm. The specific surface area is 900m 2 / g, the pore volume is 0.3cm 3 / g, the conductivity is 6S / cm;

[0025] Wherein, the preparation method of described composite nanomaterial comprises the following steps:

[0026] (1) Solution preparation: Weigh sucrose, concentrated nitric acid, water and template agent polyethylene glycol PEG-2000 according to the weight ratio of 1:0.01:6:0.7, mix and stir evenly for 5 hours to obtain solution A; Weigh an appropriate amount of carbon and nitrogen sources, then add a certain amount of solvent methanol, and stir at room temperature for 2 hours to obtain solution B;

[0027] (2) Preparation of composite nanomaterials: First, transfer solution A to a reaction kettle lined with polytetrafluoroet...

Embodiment 2

[0029] A composite nanomaterial, composed of carbon nitride and 75wt% carbon nanofibers accounting for 25wt% of the composite material, the composite nanomaterial is in the form of a fiber, the diameter of the fiber is 10 nm, and the length is 800 nm. The specific surface area is 950m 2 / g, the pore volume is 0.35cm 3 / g, the conductivity is 6S / cm;

[0030] Wherein, the preparation method of described composite nanomaterial comprises the following steps:

[0031] (1) Solution preparation: Weigh sucrose, concentrated nitric acid, water and template agent polyethylene glycol PEG-2000 according to the weight ratio of 1:0.1:6:0.8, mix and stir evenly for 5 hours to obtain solution A; Weigh an appropriate amount of carbon and nitrogen sources, then add a certain amount of solvent methanol, and stir at room temperature for 2 hours to obtain solution B;

[0032] (2) Preparation of composite nanomaterials: first transfer the solution A to a reaction kettle with a polytetrafluoroeth...

Embodiment 3

[0034] A composite nanomaterial, composed of 30wt% carbon nitride and 70wt% carbon nanofibers, the composite nanomaterial is in the form of a fiber, the diameter of the fiber is 15 nm, and the length is 700 nm. The specific surface area is 900m 2 / g, the pore volume is 0.4cm 3 / g, the conductivity is 8S / cm;

[0035] Wherein, the preparation method of described composite nanomaterial comprises the following steps:

[0036] (1) Solution preparation: Weigh sucrose, concentrated nitric acid, water and template agent polyethylene glycol PEG-2000 according to the weight ratio of 1:0.15:5:0.8, mix and stir evenly for 6 hours to obtain solution A; Weigh an appropriate amount of carbon and nitrogen sources, then add a certain amount of solvent methanol, and stir at room temperature for 2 hours to obtain solution B;

[0037](2) Preparation of composite nanomaterials: first transfer the solution A to a reaction kettle with a polytetrafluoroethylene liner, conduct a hydrothermal reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com