Resin-coated metal plate for container and production method therefor

一种制造方法、金属板的技术,应用在化学仪器和方法、家用容器、金属层状产品等方向,达到优异取出性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

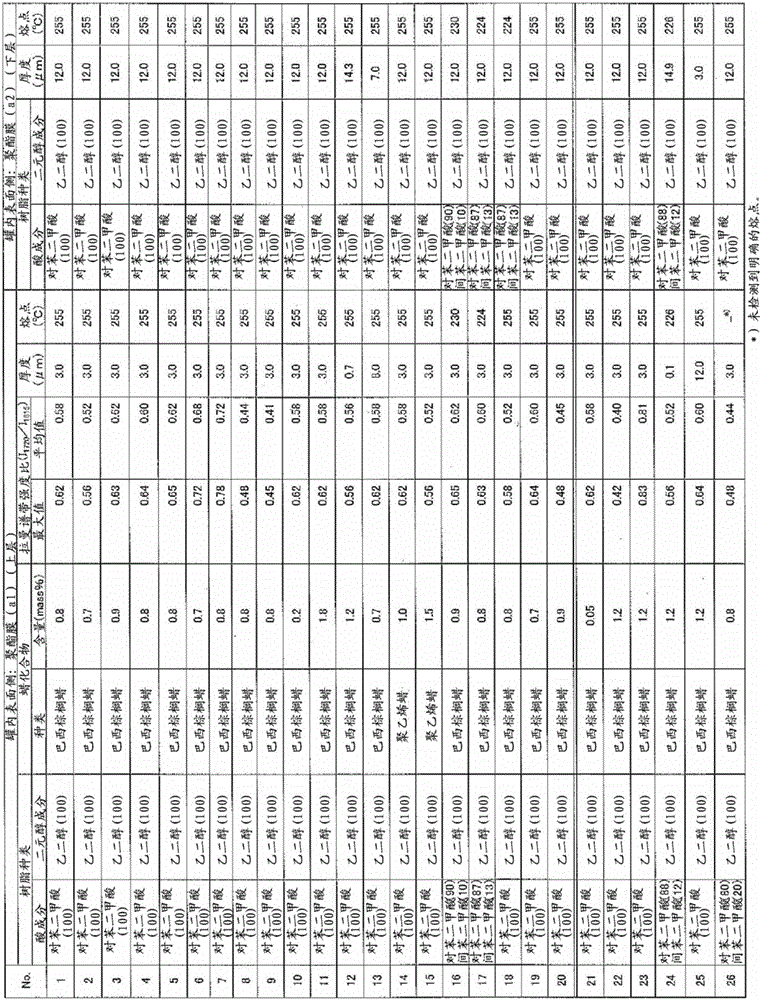

[0099] Hereinafter, examples of the present invention will be described.

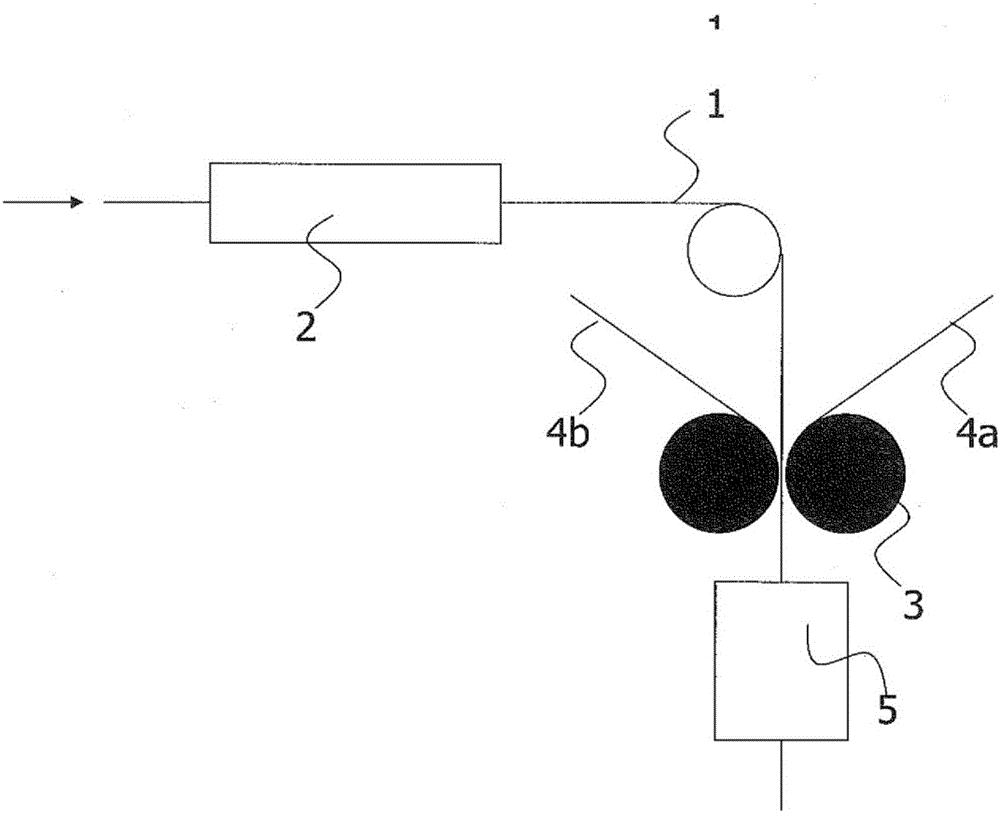

[0100] (Manufacturing method of metal plate)

[0101] A steel plate having a thickness of 0.18 mm and a width of 977 mm subjected to cold rolling, annealing, and temper rolling was degreased, pickled, and then chrome-plated to produce a chrome-plated steel sheet (TFS). Chromium plating is in the presence of CrO 3 , F - , SO 4 2- Chromium plating in a chrome bath containing CrO after intermediate rinsing 3 , F - Electrolysis in the chemical conversion treatment solution. At this time, adjust the electrolysis conditions (current density, electrical quantity, etc.), and adjust the metal chromium adhesion amount and the chromium hydroxide adhesion amount to be 120 mg / m in Cr conversion. 2 , 15mg / m 2 .

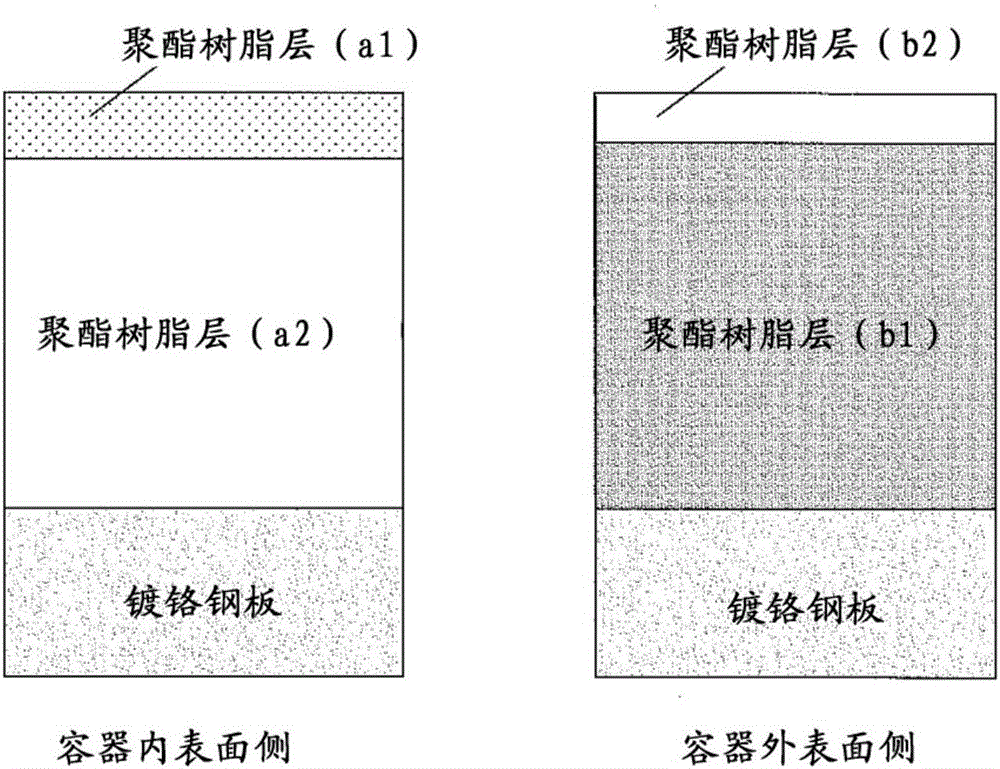

[0102] (Manufacturing method of film for resin coating on container inner surface side)

[0103] A wax compound is mixed with a polyester resin obtained by polymerizing the acid component and the d...

Embodiment 2

[0188] (Manufacturing method of metal plate)

[0189] A metal plate was produced by the same method as in Example 1.

[0190] (Manufacturing method of film for resin coating on container inner surface side)

[0191] For the acid components and glycol components shown in Table 6, all the copolymerization components other than terephthalic acid as the acid component were polymerized with ethylene glycol to obtain polyethylene terephthalate or copolymerized polyethylene terephthalate. Ethylene glycol dicarboxylate, polybutylene terephthalate, which is polymerized by terephthalic acid and butylene glycol, is further mixed to make a polyester resin. A wax compound is mixed with the polyester resin to form a resin composition, and the resin composition is dried and melted according to a conventional method. After being co-extruded through a T-die, it is cooled and solidified on a cooling drum to obtain a non-drawn The film is stretched, and then biaxially stretched and heat-set to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com