Process for preparing thermally conductive oriented uhmwpe products and products obtained therefrom

A technology with high thermal conductivity and process technology, applied in the field of high thermal conductivity oriented ultra-high molecular weight polyethylene products and its preparation, can solve the problems of energy-intensive process, troublesome, and limited commercial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

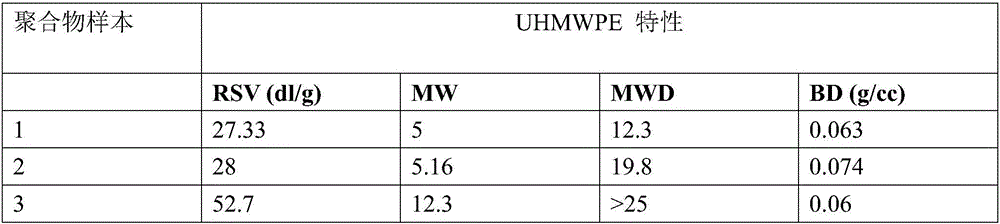

[0036] Films were prepared using three polymer samples with the following properties (Table 1), maintaining different draw ratios. Although the RSV and molecular weight (MW) of samples 1 and 2 were similar, sample 2 had a higher molecular weight distribution than sample 1. The RSV, MW and MWD of sample 3 are higher than those of samples 1 and 2.

[0037]Table 1

[0038]

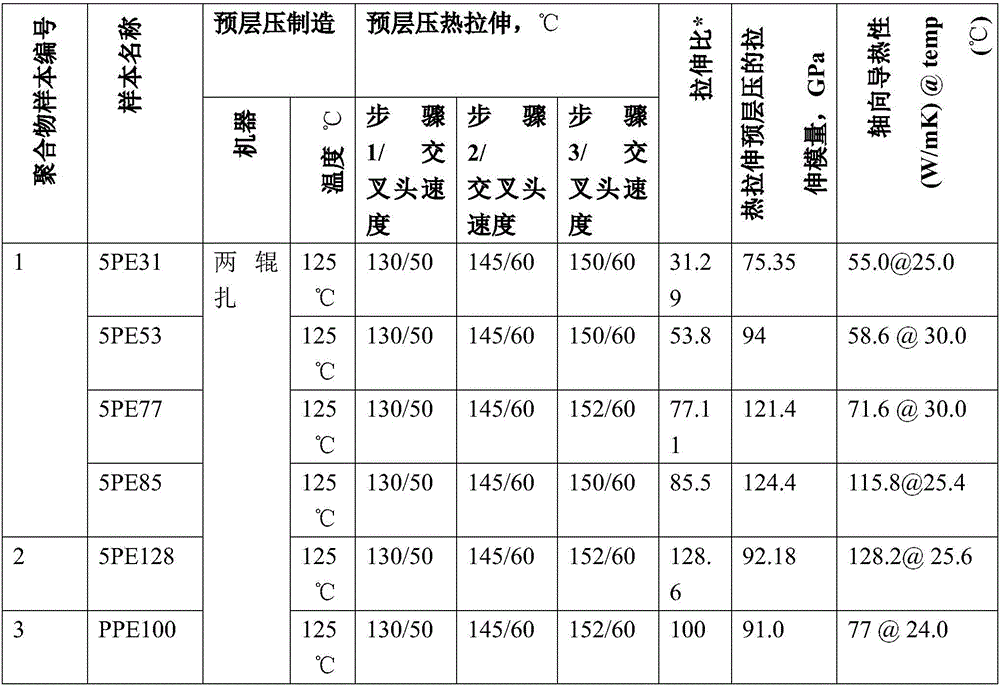

[0039] Table 2 shows the stretch film sample preparation conditions and their tensile and thermal properties. The highest stretch ratio is the limit beyond which the film will break.

[0040] From sample 1, it can be seen that the axial thermal conductivity of the prepared stretched film increases with the increase of the tensile modulus, which is related to the stretch ratio (Table 2). The results show that Polymer Sample 2 can be stretched by 128.6 times and has a thermal conductivity of 128.2 W / mK, while the tensile modulus is lower than that of Polymer Sample 1 stretched film with a lower draw ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com