Preparation method of crystalline flake graphite filled polypropylene high-thermal-conductivity composite material and mold

A flake graphite and composite material technology, applied in the field of polymer composite materials, can solve the problems of low thermal conductivity, high radial thermal conductivity of composite materials, increase thermal conductivity anisotropy of composite materials, etc., so as to improve the vertical orientation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

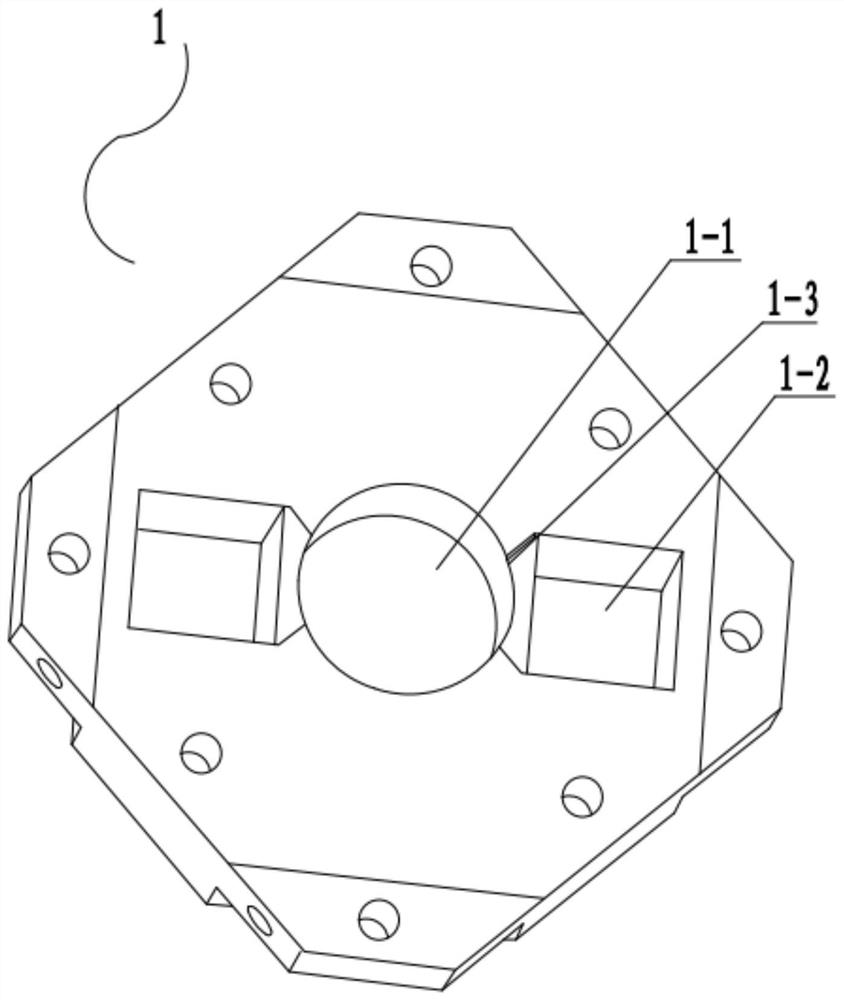

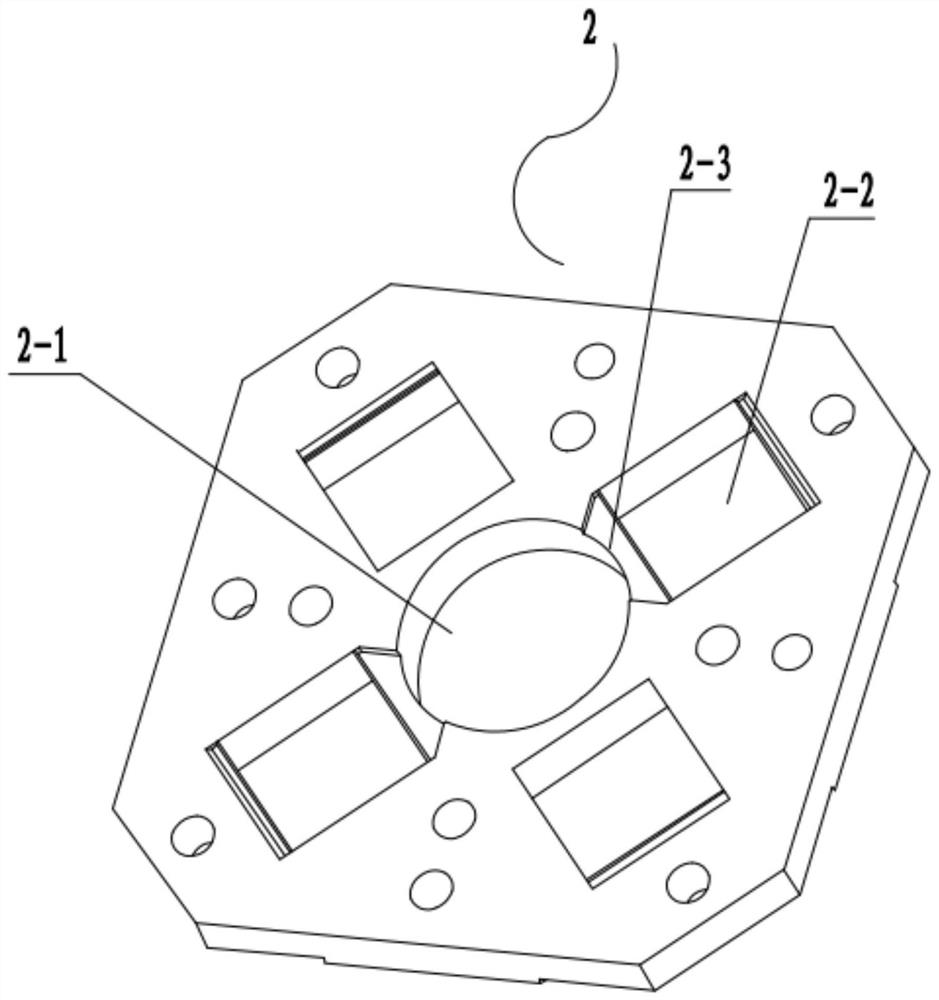

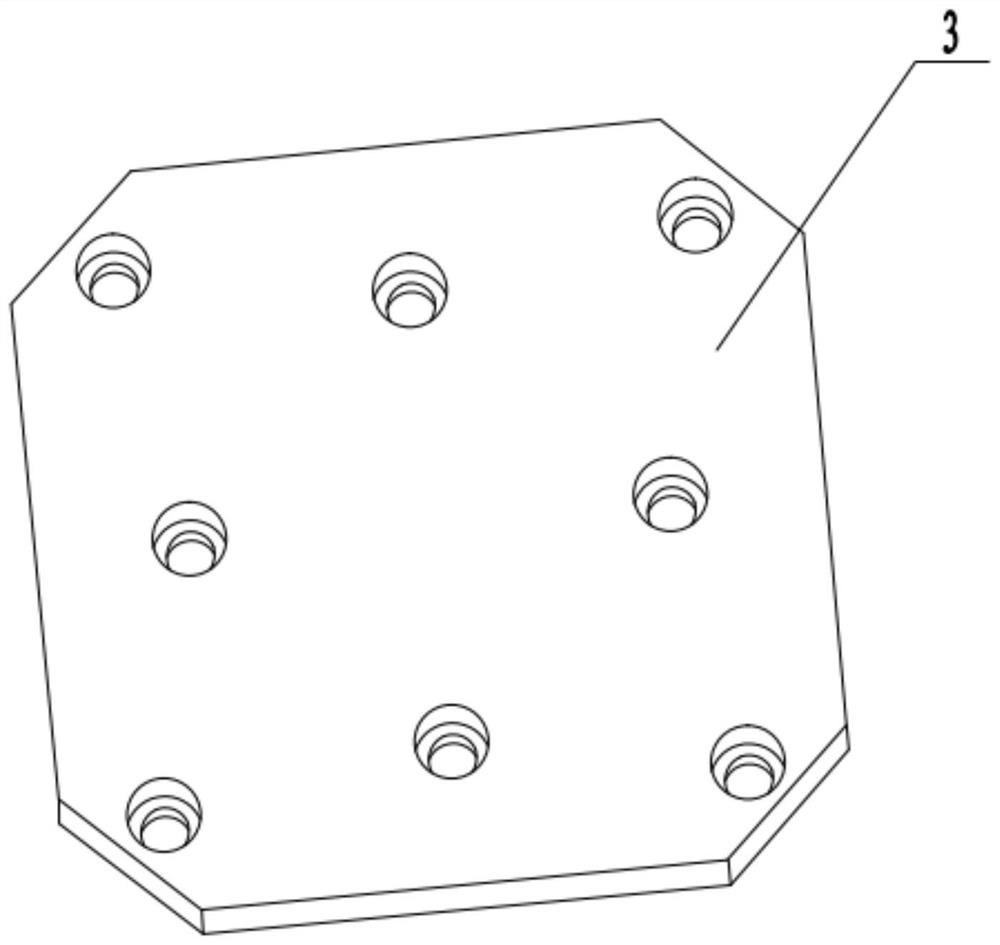

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Add 0.2 parts by mass of coupling agent KH-550 to absolute ethanol with 4 parts by mass, ultrasonicate for 30 minutes, and mix evenly with 30 parts by mass of graphite flakes with a particle size of 15 μm at high speed, and then place them in a high-temperature drum Dry in an air drying oven at 110°C for 1 hour.

[0032] Step 2: Prepare the treated flake graphite, polypropylene S2040 with 50 parts by mass, polypropylene 230 with 20 parts by mass, antioxidant 1010 with 0.7 parts by mass, flow agent with 1 part by mass, 0.7 parts by mass The lubricant zinc stearate is mixed at high speed, and then mixed with an open mill. The mixing conditions: gap adjustment and mixing times are as follows: 3 grids 8 times, 5 grids 2 times, 7 grids 2 times, 9 grids 2 times , 11 grids 2 times; the temperature of the mill is: the front roller is 185°C, and the rear roller is 180°C. After the mixing is completed, a uniform masterbatch is obtained.

[0033] Step 3: Put the masterbat...

Embodiment 2

[0035] Step 1: 40 parts by mass of polypropylene K1035, 20 parts by mass of polypropylene 1937, the coupling agent is KH-560, the rest of the conditions are the same as in Example 1, and the amount of materials used is shown in Table 1.

[0036] Step 2: the antioxidant is antioxidant 1076, the lubricant is calcium stearate, and all the other conditions are the same as in Example 1.

[0037] Step 3: The steps are the same as in Example 1.

[0038] The detailed ratio is shown in Table 1 below:

[0039] Table 1 Flake graphite filled polypropylene high thermal conductivity composite material formula

[0040] components parts by mass Coupling agent KH-560 0.3 Absolute ethanol 6 flake graphite 40 Polypropylene K1035 40 Polypropylene 1937 20 Antioxidant 1076 0.6 flow agent 1 Zinc stearate 0.6

Embodiment 3

[0042] Step 1: 35 parts by mass of polypropylene 1940, 20 parts by mass of polypropylene M2600, the coupling agent is NDZ-102, the rest of the conditions are the same as in Example 1, and the amount of materials used is shown in Table 2.

[0043] Step 2: The antioxidants are antioxidant 1076 and antioxidant 168, and the rest of the conditions are the same as in Example 1.

[0044] Step 3: Put the masterbatch into the mold and melt it at high temperature. Under the pressure injection of the plunger, pass through the lower die and the upper die with an opening height of 0.5mm at a uniform speed along the horizontal and vertical directions respectively. The molding pressure is 7Mpa, and the other conditions are the same as Example 1 is the same.

[0045] The detailed ratio is shown in Table 2 below:

[0046] Table 2 Flake graphite filled polypropylene high thermal conductivity composite material formula

[0047] components parts by mass Coupling agent NDZ-102 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com