a field emission tube

A technology of field emission tube and carbon tube fiber, which is applied in the direction of X-ray tube electrodes and X-ray tube components, etc., can solve the problems of complex process, grid melting deformation, expensive production cost, etc., and achieve high axial thermal conductivity , Simplified manufacturing process, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The field emission X-ray tube of the present invention will be further described in detail below.

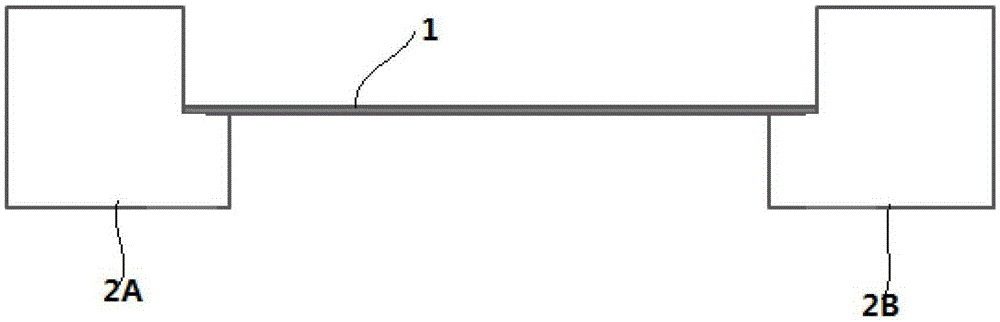

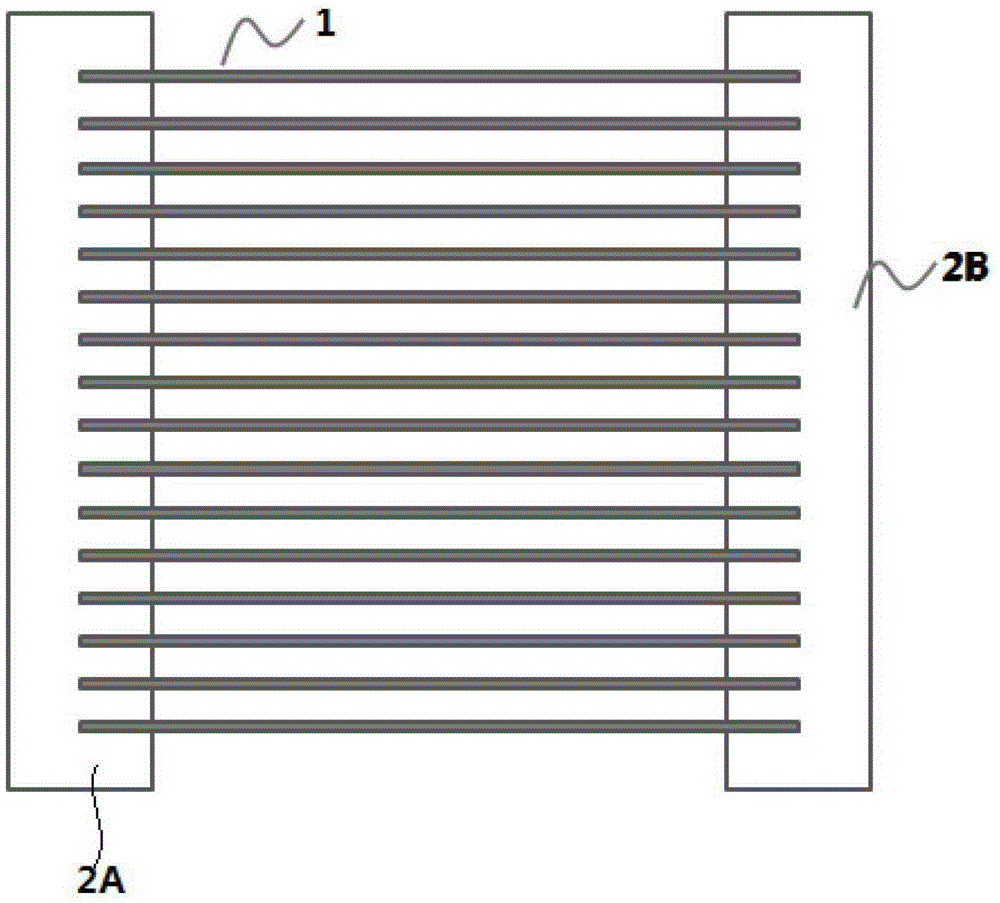

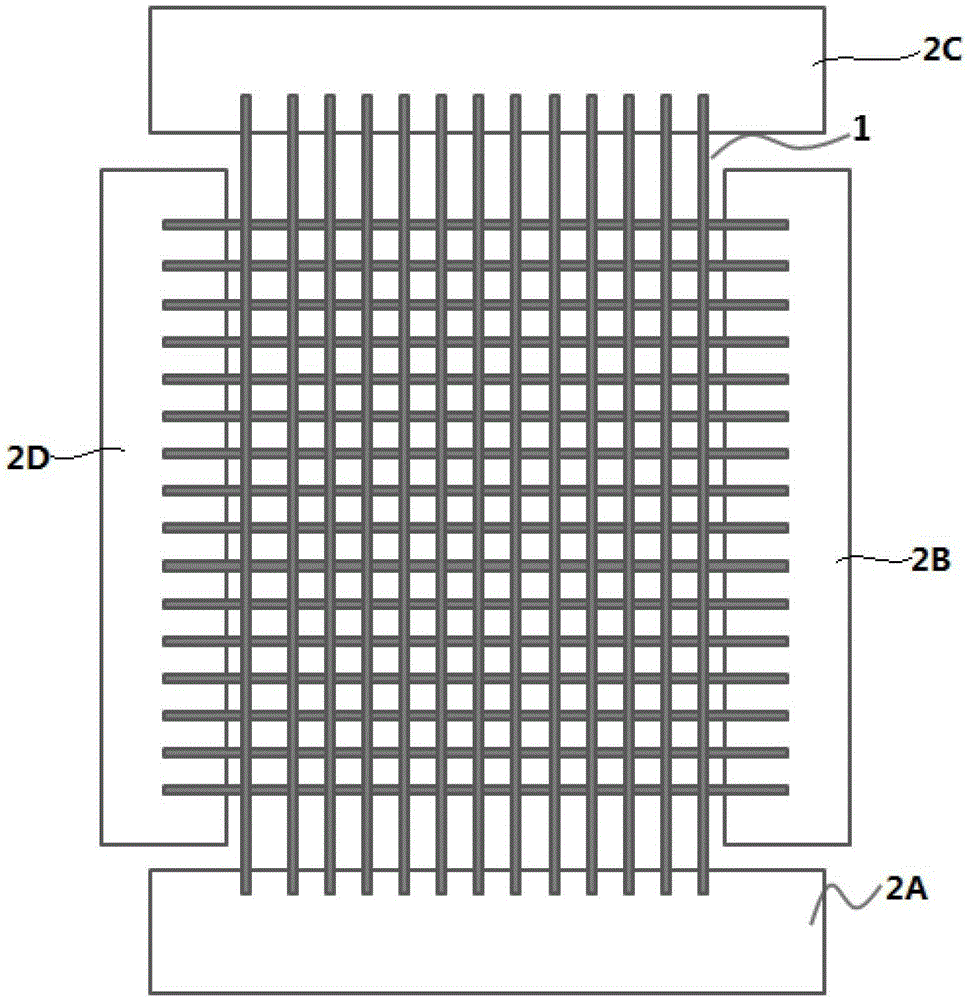

[0014] The existing field emission X-ray tubes all include a cathode, an anode and a grid, wherein the grid includes a bracket and carbon tube fibers connected to the bracket. Because carbon nanotubes, the material of carbon tube fibers, have large specific surface area, high thermal stability (remains stable at 3400°C), high mechanical strength, high axial thermal conductivity (about 3500W / (m.K) and good electrical conductivity. Become a potential heat dissipation conductive material. People have carried out extensive research on carbon tubes and proved that they have excellent thermal conductivity (Nanotechnology, 2000, 11, 65; Physical Review B, 2002, 66, 165440). As a heat dissipation device Applied research has also made some progress, such as CN102318438A uses carbon nanotube ink as a printed heat dissipation material, CN201110207615.8 reports a LED lamp that uses c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com