Cryogenic liquid automatic filling system and method

A cryogenic liquid and automatic technology, which is applied in the field of air separation, can solve the problems of energy loss, large safety hazards, and the inability to realize automatic pump stop operation, etc., to achieve the effect of reducing product loss and cooling loss, and reducing product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

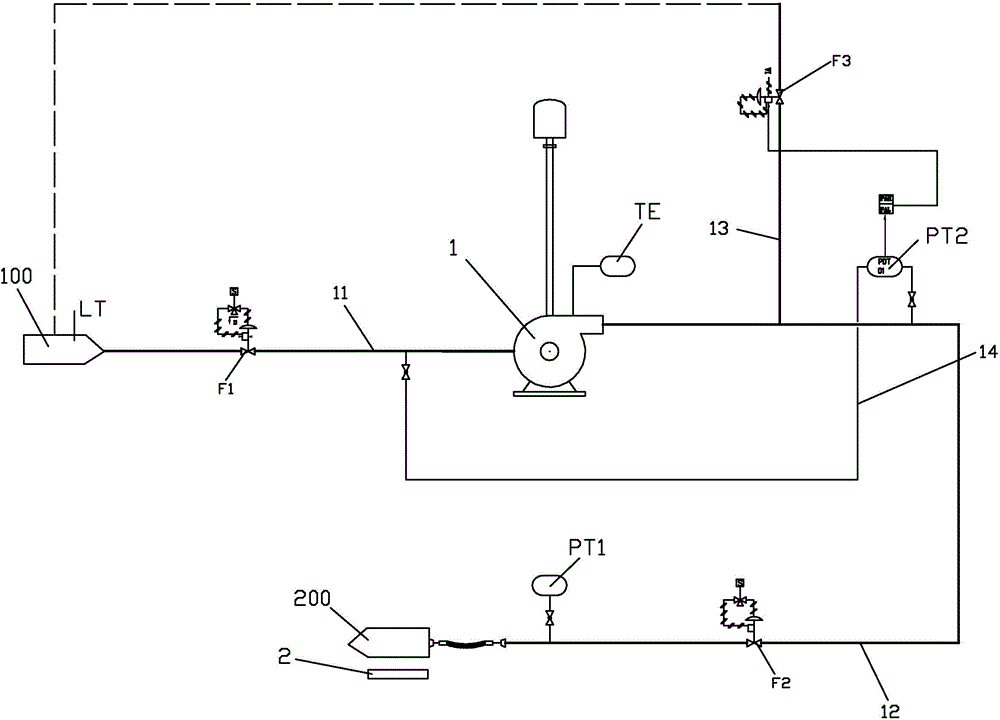

Method used

Image

Examples

Embodiment 1

[0032] Embodiment one (order is 20 tons of liquid oxygen, liquid oxygen tank car filling)

[0033] 1) Set the filling target weight value of the weighing instrument at the filling position to 20,000kg, set the liquid level of the storage tank to be lower than 5% to stop filling, and the preset value of the outlet temperature of the filling pump to be -60°C. The pressure setting of the filling pipeline is 100KPa, and the preset cooling time of the filling pump is 1800 seconds;

[0034] 2) When the liquid oxygen tanker is driving on the weighing instrument (weighing floor scale) at the filling position, the controller judges that the filling condition is met, that is, the weighing instrument at the filling position displays a weight of 6380kg, which is greater than 5000kg (indicating that the filling container has been filled). in place); the filling pipeline pressure display is 230KPa, which is 100KPa higher than the set value (indicating that the filling hose is well connected...

Embodiment 2

[0039] Embodiment two (order is liquid nitrogen 15 tons, liquid nitrogen tank car filling)

[0040] 1) Set the filling target weight value of the weighing instrument at the filling position to 15,000kg, set the liquid level of the storage tank to be lower than 5% to stop filling, and the preset value of the outlet temperature of the filling pump to be -55°C. The set value of the filling pipeline pressure is 80KPa, and the preset cooling time of the filling pump is 1800 seconds;

[0041] 2) When the liquid nitrogen tanker is driving on the weighing instrument (weighing floor scale) at the filling position, the controller judges that the filling condition is met, that is, the weighing instrument at the filling position shows a weight of 58,000kg, which is greater than 5,000kg (indicating that the tanker already in place); the filling pipeline pressure display is 160KPa, which is 100KPa higher than the set value (indicating that the filling hose is well connected); the liquid level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com