A high-voltage power battery with controllable liquid injection volume and its preparation method

A technology with high voltage and liquid injection volume, which is applied in the direction of non-aqueous electrolyte battery electrodes, battery electrodes, secondary batteries, etc. Liquid leakage and other problems can be improved to achieve the effect of improving the consistency of mechanics and realizing the uniformity and consistency of the injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The high-voltage power lithium-ion battery of the present invention is designed to meet the power supply requirements of various electric vehicles. Therefore, according to the different application occasions of the battery, the design value of the battery cell voltage is also different, that is, the number of stacked battery cells that make up the battery cell different. At present, the operating voltages of small electric vehicles (including electric bicycles, electric motorcycles and electric sightseeing cars, etc.) are generally 36V, 48V, 64V, 74V and 80V, and large and medium-sized electric vehicles (including pure electric passenger vehicles, pure electric trucks, etc.) , hybrid electric vehicles, electric buses, etc.) the working voltage range is generally 120V ~ 500V.

[0047] This embodiment is a pure electric passenger car power supply, its operating voltage is 320V, the selected cell operating voltage platform is 320V, and the number of superimposed battery un...

Embodiment 2

[0059] This embodiment provides a method for manufacturing a 320V high-voltage battery 600:

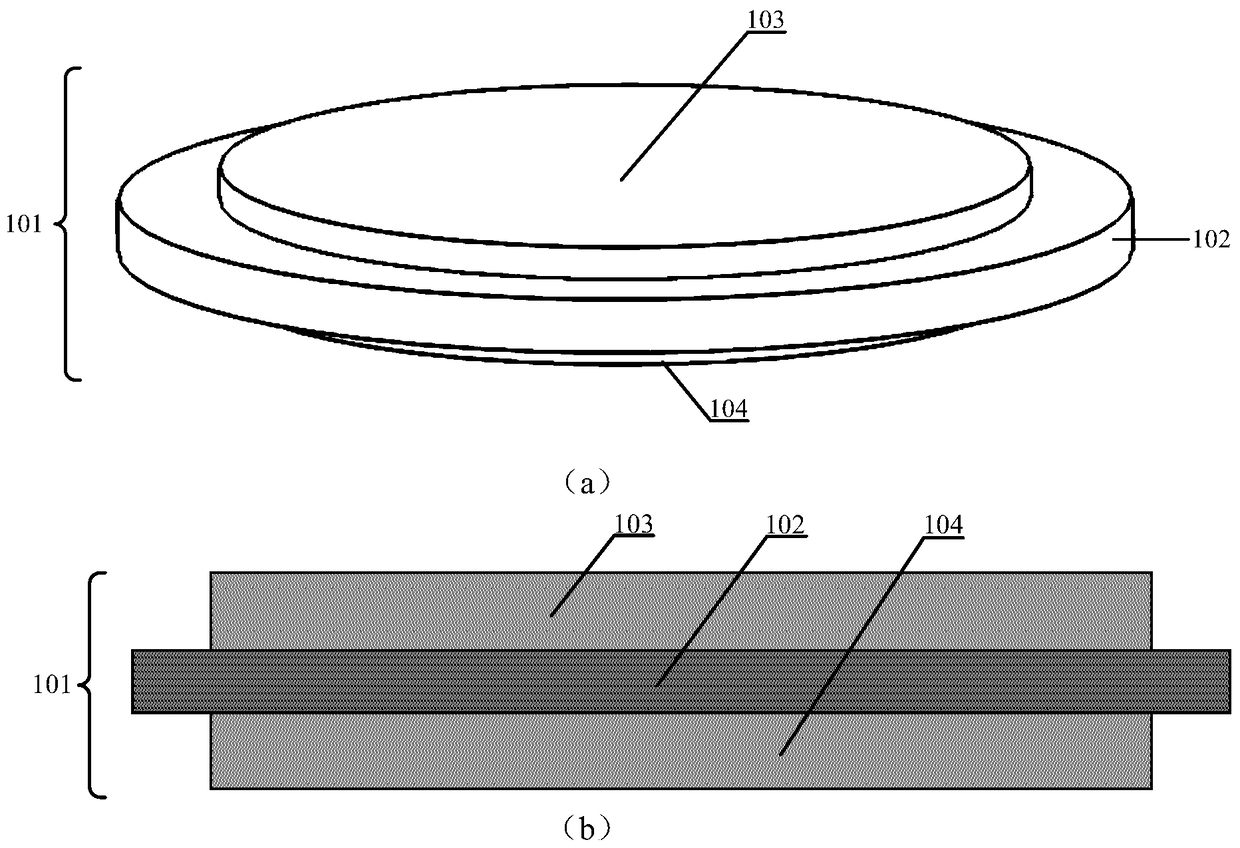

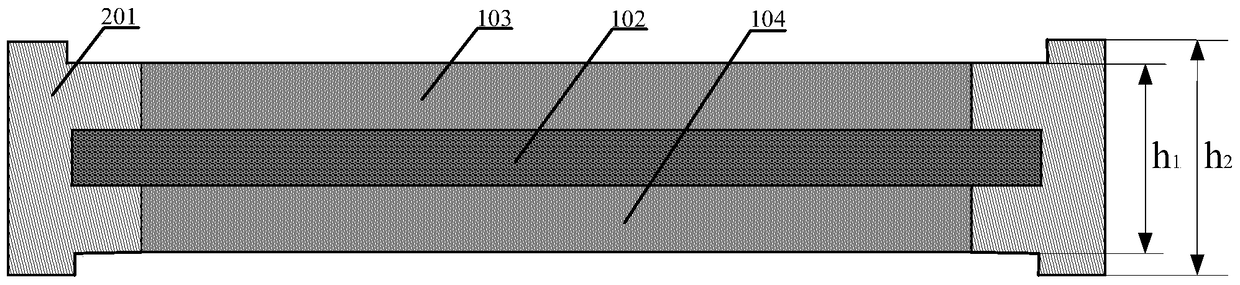

[0060] Step 1: Preparation of bipolar electrode sheet 101: apply circular positive electrode coating 103 and negative electrode coating 104 respectively on the positive electrode surface and negative electrode surface of the circular bipolar current collector 102 by spraying, and prepare A bipolar electrode sheet 101 is obtained, wherein the bipolar current collector 102 is a metal-based composite conductive film with a diameter of 39.4 cm and a thickness of 80 μm, and the positive electrode coating 103 sprayed on both sides of the bipolar current collector 102 has a diameter of 38.6 cm. The thickness is 140 μm, the porosity is 35%, the diameter of negative electrode coating 104 is 38.6 cm, the thickness is 120 μm, and the porosity is 30%; In contact with the positive and negative electrode coatings, the inner diameter of the annular sealing ring 201 is 38.6 cm, the outer diameter is ...

Embodiment 3

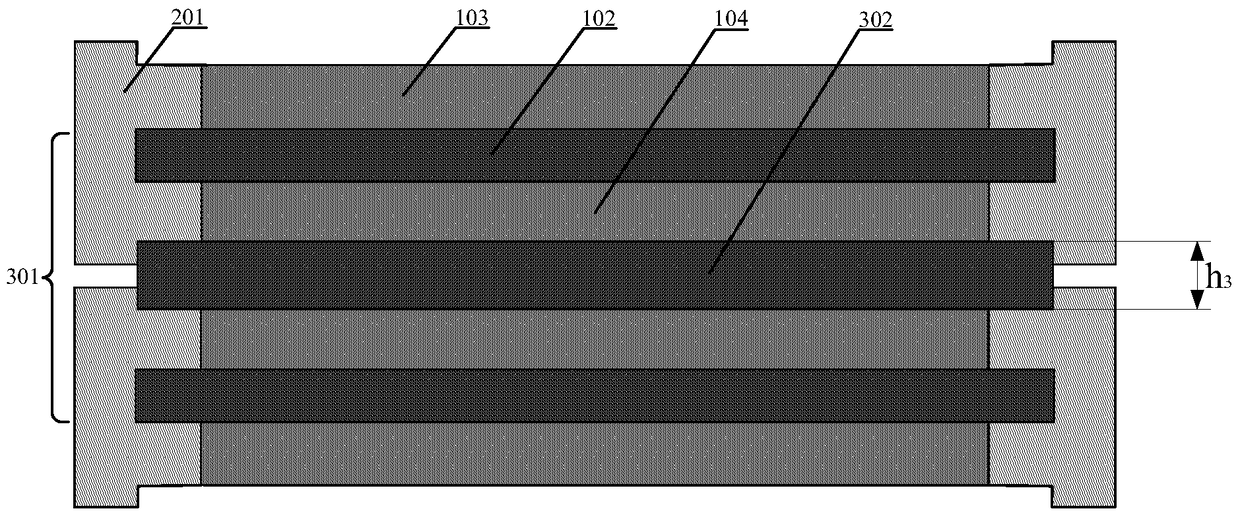

[0072] In this embodiment, according to the diameter d of the positive electrode coating 103 sprayed on both sides of the bipolar current collector 102 1 , thickness m 1 , and porosity ρ 1 , the diameter d of the negative electrode coating 104 2 , thickness m 2 , and porosity ρ 2 , the amount of electrolyte absorbed by the electrode coating can be calculated as: then, the amount of electrolyte squeezed out from the separator 302 is greater than or equal to the amount Q of electrolyte absorbed by the electrode coating, using the porosity of the separator ρ 3 , diameter d 3 , the liquid absorption rate of the isolation layer q (70%2 -h 1 ), then the thickness h of the isolation layer before compression 3 for:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com