Spine vertebral plate bridging system

A lamina bridge and spine technology, applied in the field of spine lamina bridge system, can solve the problems of stress shielding, unfavorable lamina molding growth, artifacts affecting clinical observation, etc., to reduce side effects, excellent biocompatibility, good long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

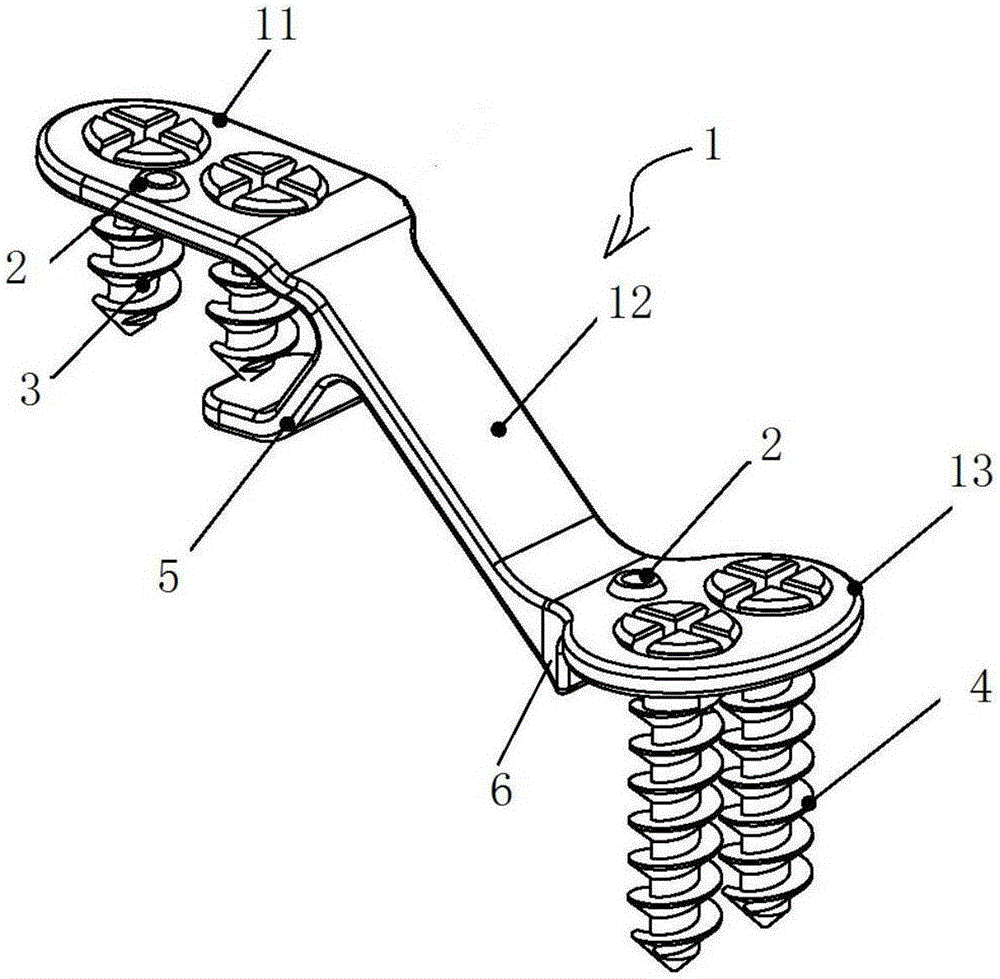

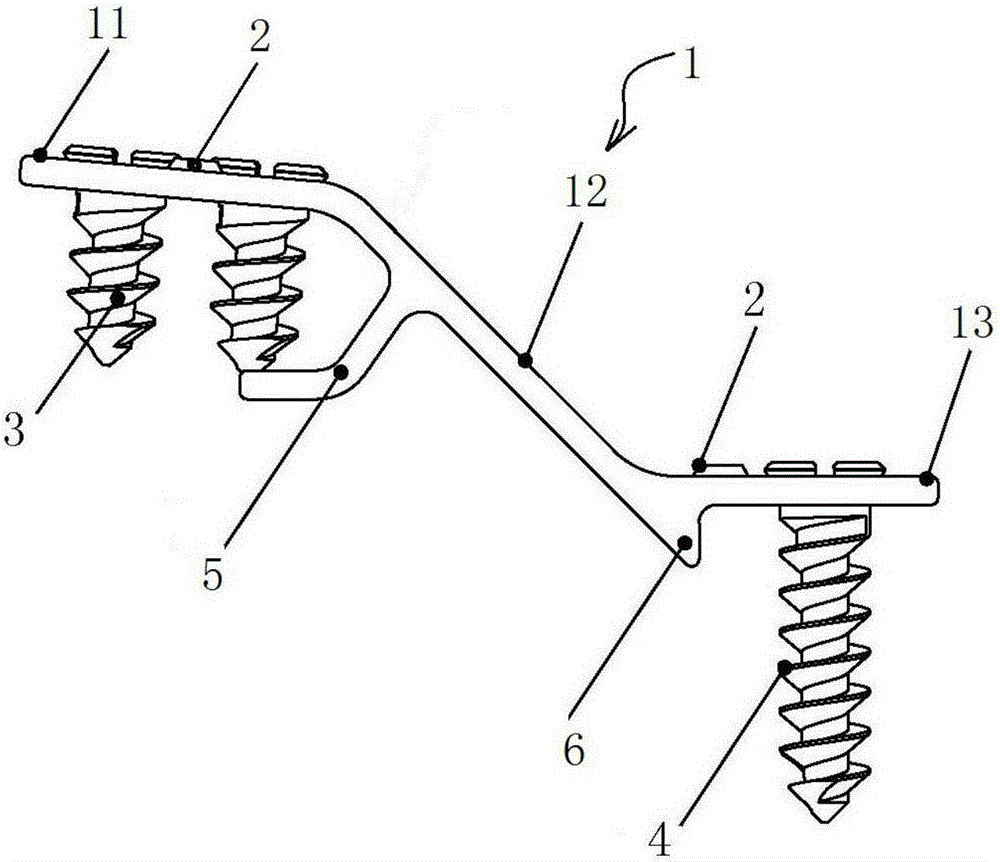

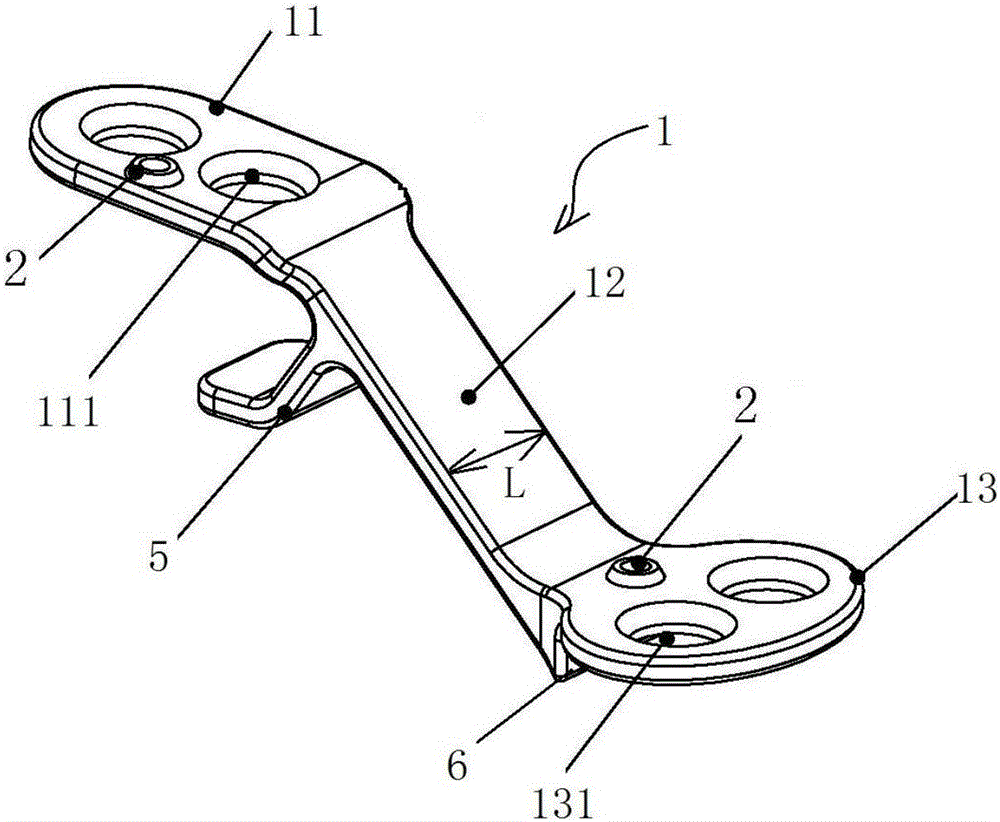

[0039] Such as Figure 1 to Figure 5 As shown, the spinal lamina bridging system includes a fixed plate main body 1, a developing marker 2, short bone screws 3 and long bone screws 4. The fixed plate main body 1 consists of a lamina fixed end 11, an inclined support rib 12 and a side mass fixed end 13. Connected, and the whole is a kind of "Z" shape, two straight through holes 111 are arranged on the fixed end 11 of the lamina, the short bone nails 3 are matched with the straight through holes 111, and the fixed end 13 of the side block is provided with Two horizontal through holes 131, the long bone nail 4 cooperates with the horizontal through holes 131. The short bone nail 3 is provided with an initial self-tapping cutting edge 31 . The long bone nail 4 is provided with an initial self-tapping cutting edge 41 .

[0040] In the present invention, the main body 1 of the fixed plate adopts an ultra-thin design, specifically: the fixed end 11 of the lamina, the inclined suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Maximum width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com