Method and device for automatic cleaning and flux application of solar battery strips

A technology for automatic cleaning of solar cells, applied to the surface coating liquid device, auxiliary device, cleaning method and utensils, etc., can solve the problems of easy-to-produce cracks and hidden cracks, easy to be polluted, easy to corrode mechanical devices, etc. , to achieve the effects of reducing the influence of cells, reducing the welding defect rate, and simplifying the welding machine device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

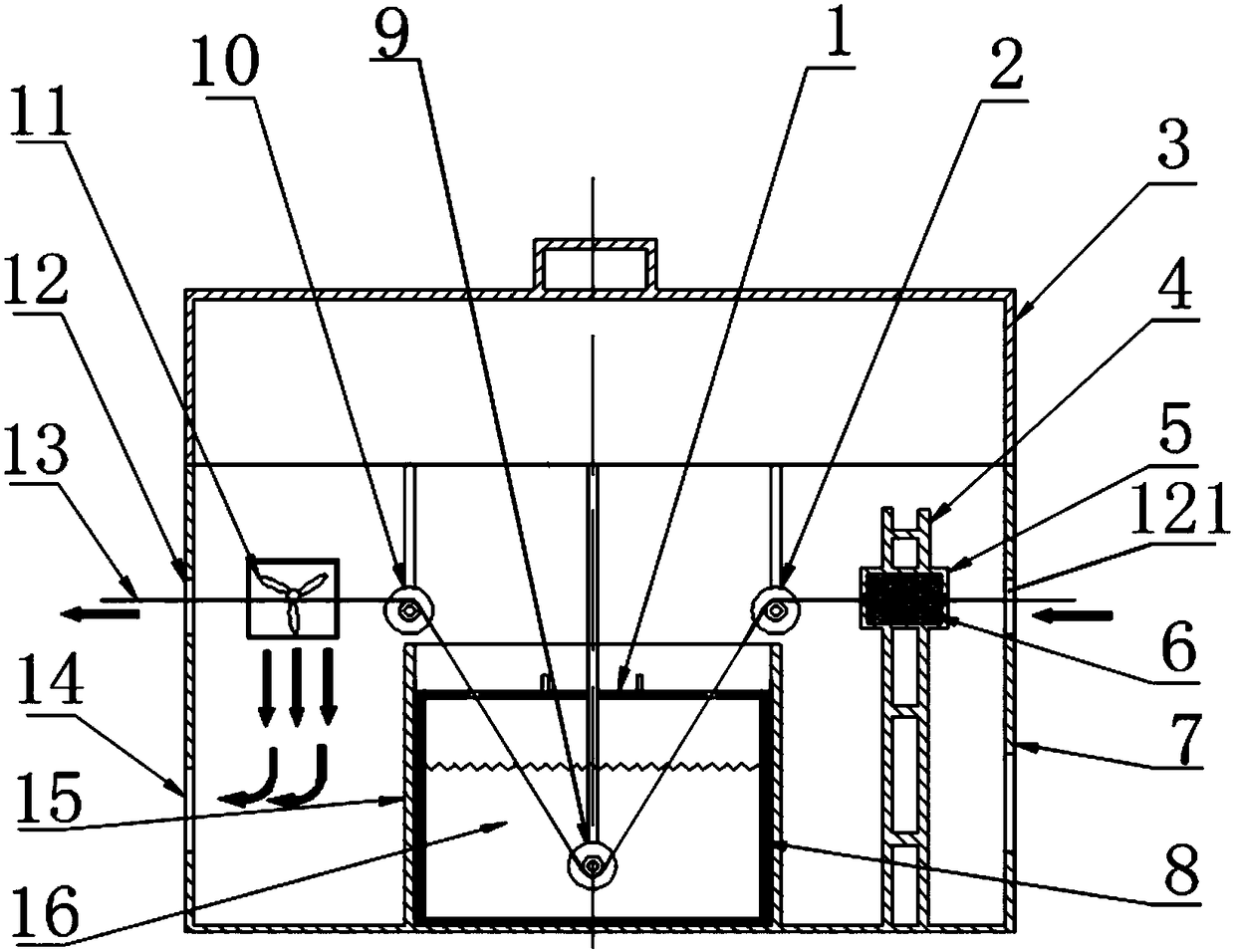

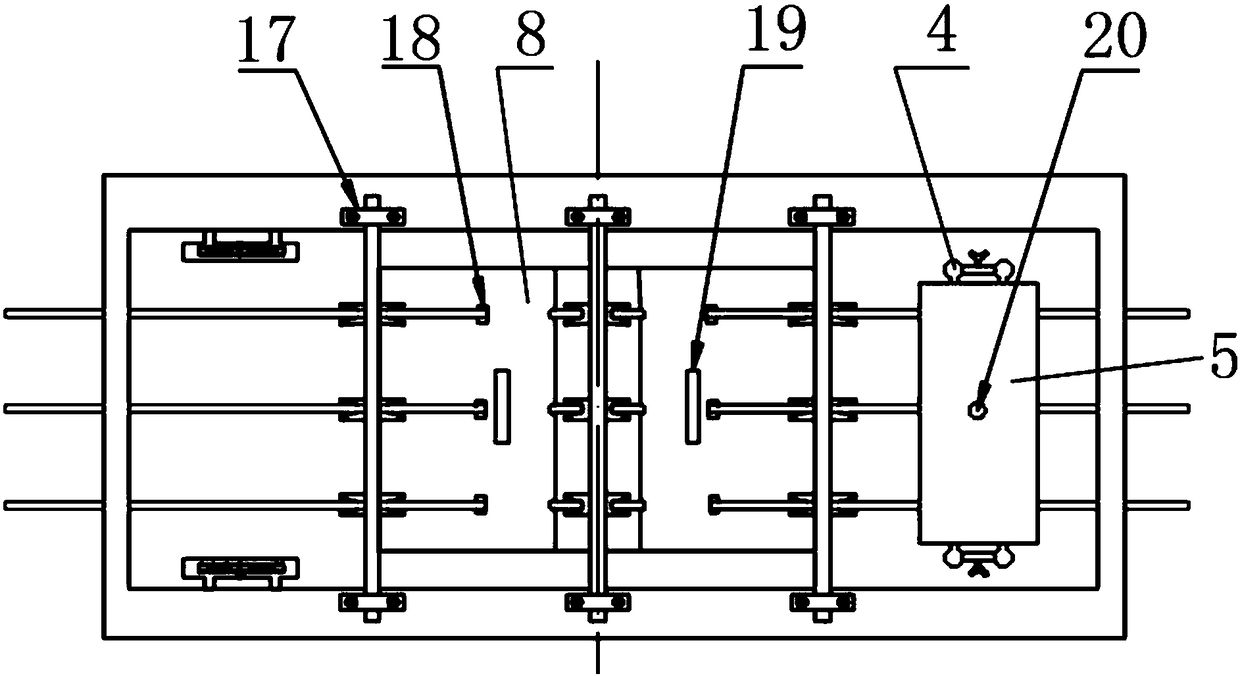

[0033] 1. Lay the welding strips according to the path, specifically, multiple welding strips (depending on the number of grid lines of the battery sheet, including 3 grids, 4 grids, 5 grids, etc.) in order to pass around the right side of the middle of the box in a strip shape Soldering ribbon inlet, cleaning cotton in the box cover, right short rod fixed pulley V-shaped groove, flux container box cover right square hole, long rod fixed pulley V-shaped groove, flux container box cover left square hole, The left short rod fixes the V-shaped groove of the pulley, the drying chamber, and the strip-shaped welding ribbon outlet on the left side of the middle part of the box body.

[0034] 2. Tighten the locking mechanism of the cleaning device so that the welding ribbon has sufficient friction when passing through the cleaning cotton; inject alcohol to ensure that the cleaning cotton is wet to clean the adhesion of the welding ribbon.

[0035] 3. Adjust the length of the long pole...

Embodiment 2

[0041] The process is the same as in Example 1, except that no alcohol cleaning agent is added to the ribbon cleaning device, the heating power of the drying device is controlled at a temperature of 50° C., and the flow velocity is at 4 levels (equivalent to 3 m / s). Start the stringer and count the defect rates of cell welding. The total defect rate of cell welding is 0.4%, the rate of virtual welding and open welding is 0.18%, and the rate of splinters and hidden cracks is 0.20%.

Embodiment 3

[0043] The process is the same as in Example 2, except that the support of the ribbon cleaning device is not fastened (the device has no cleaning effect), the heating power of the drying device is controlled at a temperature of 40°C, and the flow velocity is set at 5 levels (equivalent to 1m / s). Start the stringer device, and count the defect rates of cell welding. The total defect rate of cell welding is 0.55%, the rate of virtual welding and open welding is 0.20%, and the rate of splinters and hidden cracks is 0.34%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com