Method for evaluating polymer hot-melt welding performance

A hot-melt welding and polymer technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of alignment degree influence, internal knotting, large welding scars, etc., to reduce the welding defective rate and detect the required materials Less, effective welding performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention has no special limitation on the preparation method of the polymer pellets, which is obtained by premixing the polymer material with additives (additives are also optional) well known to those skilled in the art, and then granulating through a twin-screw extruder.

[0049] In the present invention, the vacuum lamination device is preferably a vacuum lamination machine, so that the entire vacuum lamination process is kept in a vacuum state; the temperature of the vacuum lamination is preferably 110°C to 180°C, and the melting time is preferably 2min to 3min; the number of times of pressure relief of the vacuum lamination is preferably 3 to 5 times, more preferably 3 to 4 times; the pressure of the vacuum lamination is preferably 8MPa to 12MPa, more preferably 10MPa; The holding time of the vacuum film pressing is preferably 1 min to 2 min.

[0050] After the polymer film is obtained, the present invention prepares samples of the obtained polymer fil...

Embodiment 1

[0062] Heat the PVC plasticizer to 40°C and add it into a high-speed mixer to mix and plasticize it with PVC resin powder, then extrude and granulate through a twin-screw extruder to obtain PVC resin particles.

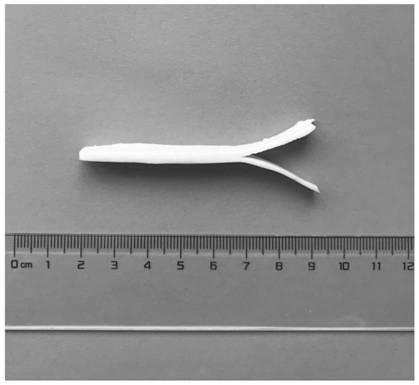

[0063] Firstly, the PVC resin particles are pressed into a film in a vacuum laminator. The lamination temperature is 160°C, melted for 2 minutes, released 3 times, and kept at 10MPa for 1 minute. The whole process is kept in a vacuum state to obtain a PVC composite film; Then cut the pressed film into rectangular splines with a width of 3 cm, a length of 7 cm, and a thickness of 1.2 mm; then set the temperature of the small open mill to 180 ° C, and preheat the cut rectangular splines on the roller surface respectively 2s, 5s, 10s, 20s and 40s, and then stick the two film samples together, pass through the gap between the two rolls of the open mill, the gap between the two rolls is 1.6mm, complete the welding, and obtain the welded film, which is further cut into Rect...

Embodiment 2

[0067] The following steps evaluate the welding performance of plasticizer 60°C PVC resin particles. The operation process is the same as in Example 1, the difference is that the PVC plasticizer is heated to 60°C and then added to a high-speed mixer to mix with PVC resin powder for plasticization .

[0068] Figure 6 Be the peeling strength-displacement curve of PVC resin particle (plasticizer 60 ℃ sample) different warm-up times among the embodiment 2; When reaching the end of displacement, the spline peels off completely; By Figure 6 It can be seen that when the preheating time increases from 2s to 20s, the peel strength gradually increases from 100N / m to 1600N / m. If the preheating time is continued to be extended to 40s, the peel strength increases very little and reaches a plateau.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com