Device and method for preparing highly oriented carbon nanotube film or fiber and its microcomb method

A carbon nanotube film and carbon nanotube fiber technology, which is applied in the field of nanomaterials to achieve the effects of improving mechanical properties, improving load transfer efficiency, and increasing macroscopic maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

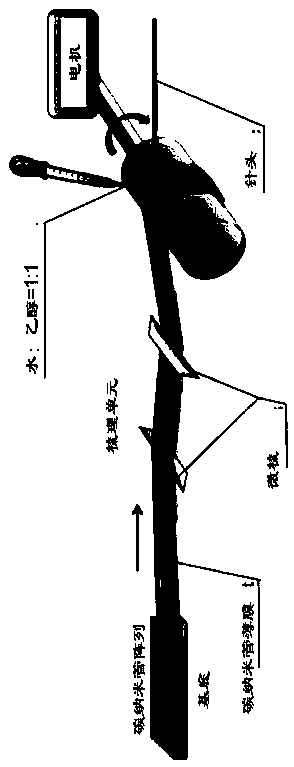

[0052] Example 1: Please refer to figure 1 , the micro-comb preparation process of the highly oriented carbon nanotube film may include the following steps:

[0053] First, pull out a single-layer carbon nanotube film from the carbon nanotube array (refer to Nature, 2002, Volume 419, Issue6909);

[0054] Afterwards, the single-layer carbon nanotube film is continuously combed with a micro-comb. The surface of the micro-comb has a row of micron-scale micro-teeth. The distance between adjacent microteeth is about 10 μm;

[0055] Afterwards, the single-layer carbon nanotube film after carding is wound on the collection shaft (winding speed about 0.2cm / s), wherein the collection shaft is pre-wrapped with a layer of polytetrafluorofilm, and, in the winding process , using ethanol as the immersion solution to infiltrate the single-layer carbon nanotube film to form a highly oriented carbon nanotube film material on the collecting shaft;

[0056] Finally, the highly oriented carbo...

Embodiment 2

[0059] Example 2: Please refer to figure 1 , the micro-comb preparation process of the highly oriented carbon nanotube fibers may include the following steps:

[0060] First, pull out a single-layer carbon nanotube film from a carbon nanotube array (Nature, 2002, Volume 419, Issue 6909);

[0061] Afterwards, the single-layer carbon nanotube film was combed continuously with a micro-comb. The surface of the micro-comb had two rows of interlaced micron-scale micro-teeth. The micro-teeth were conical in shape with a diameter of about 5 μm and a height of about 10 μm. The distance between adjacent microteeth is about 10 μm;

[0062] The carded single-layer carbon nanotube film is twisted at a twisting speed of about 1200 rpm and a collection speed of about 10 cm / min.

[0063] Afterwards, it is wound and collected with a collection shaft, and in the winding process, the soaking treatment is carried out with ethanol (analytical pure) as the soaking liquid, and carbon nanotube fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com