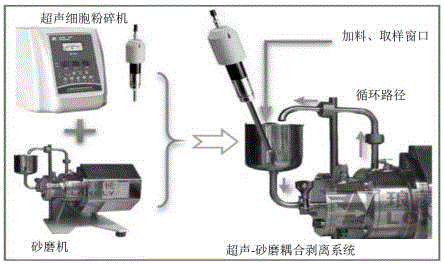

Method for preparing molybdenum disulfide nano-sheet from molybdenite through ultrasonic-sanding coupling stripping

A technology of molybdenum disulfide and molybdenite, applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problem of long peeling cycle, difficulty in obtaining molybdenum disulfide nanosheet structure with high diameter-thickness ratio, and difficult control of product morphology, etc. problem, to achieve the effect of efficient stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

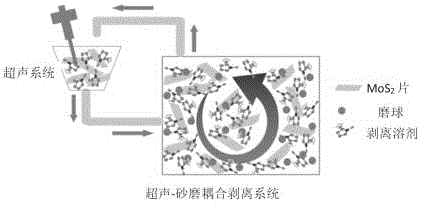

Method used

Image

Examples

Embodiment 1

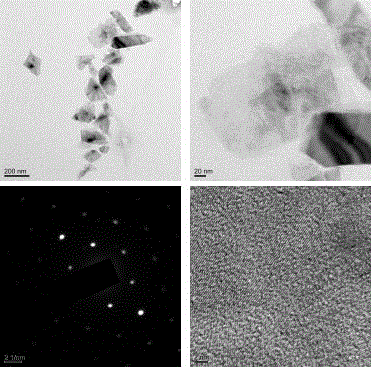

[0041] Ultrasonic-sand milling coupled to strip molybdenite to prepare molybdenum disulfide nanosheets, the steps are as follows:

[0042] Disperse 11.25 g of molybdenite fine powder in 250 mL of NMP (N-methylpyrrolidone, C 5 h 9NO) to form a suspension; 2) followed by the addition of 3.9 g PVP (polyvinylpyrrolidone, (C 6 h 9 NO)n), ultrasonic for 20 min to fully disperse; 3) then transferred into the reaction chamber of a sand mill (rotation speed 2250 rpm), and then under the action of high-energy ultrasonic (ultrasonic power 280 W), the sand mill-ultrasonic coupling stripping 6 h; 4) The exfoliated molybdenum disulfide nanosheet suspension was left to stand for about 24 h, and then centrifuged and graded at 1500 rpm, 8000 rpm, and 10000 rpm for 45 min. The solid content of the molybdenum disulfide nanosheets in the supernatant suspension after centrifugation at 1500 rpm for 45 min is used as an evaluation standard for evaluating the peeling yield: the relative concentrat...

Embodiment 2

[0055] Ultrasonic-sand milling coupled to strip molybdenite to prepare molybdenum disulfide nanosheets, the steps are as follows:

[0056] Disperse 11.25 g molybdenite fine powder in 250 mL ethanol solution (48%wt ethanol, C 2 h 5 OH) to form a suspension; 2) followed by the addition of 3.9 g of PVP (polyvinylpyrrolidone, (C 6 h 9 NO)n), ultrasonic for 20 min to fully disperse; 3) then transfer into the reaction chamber of a sand mill (2250 rpm), and then couple with each other under the action of ultrasonic (ultrasonic power 280 W) for 4 h; 4 ) Let the stripped suspension stand for about 2 h, centrifuge for classification, and centrifuge at 1500 rpm, 5000 rpm, and 8000 rpm for 45 min respectively. Subsequent processing is the same as in Example 1.

[0057] Figure 11 It is a graph of stripping yield and stripping rate of molybdenum disulfide nanosheets. With the extension of time, the stripping yield gradually increases. When ethanol solution is used as the solvent, the ...

Embodiment 3

[0059] Ultrasonic-sand milling coupled to strip molybdenite to prepare molybdenum disulfide nanosheets, the steps are as follows:

[0060] Disperse 6.25 g molybdenite fine powder in 250 mL NMP (N-methylpyrrolidone, C 5 h 9 NO) to form a suspension; 2) followed by the addition of 2.17 g of PVP (polyvinylpyrrolidone, (C 6 h 9 NO)n), sonicate for 20 min to fully disperse, and add salt (0.57gNaCl) or alkali (0.39gNaOH) stripping aid at the same time; Under the action (ultrasonic power 280 W), the mutual coupling was carried out for 4 h; 4) The stripped suspension was left to stand for about 24 h, centrifuged for grading, and centrifuged at 1500 rpm, 8000 rpm, and 10000 rpm for 45 min respectively. Subsequent processing is the same as in Example 1.

[0061] Figure 12 It is the stripping yield and rate analysis diagram of molybdenum disulfide nanosheets, NMP is the stripping solvent, and the effect of adding salt (NaCl) and alkali (NaOH) stripping aids on the stripping yield a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com