A kind of preparation method of ultrafine anthraquinone

A technology for anthraquinone and quinone finished products, which is applied in the field of preparation of ultra-fine anthraquinone to achieve the effect of small anthraquinone particle size and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

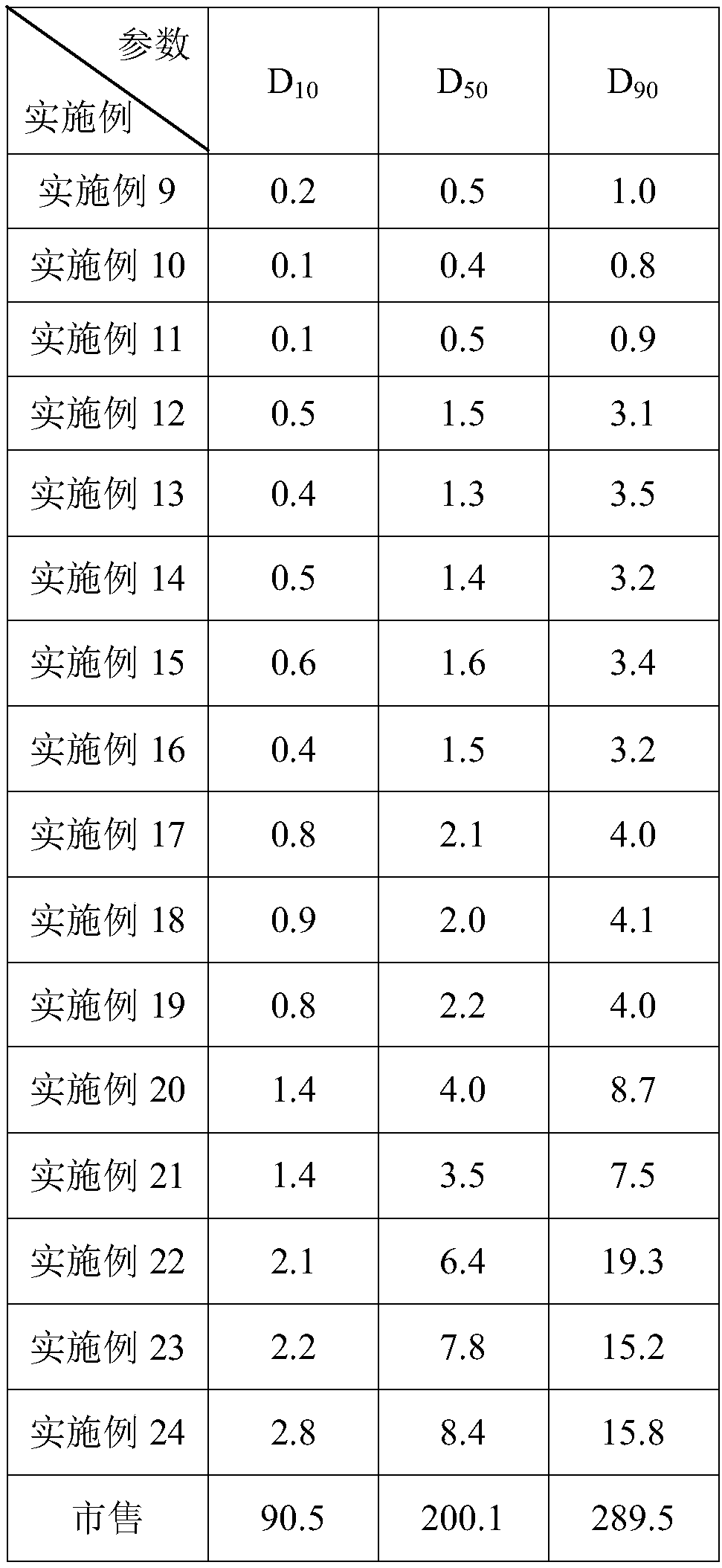

Examples

Embodiment 1-3

[0029] Embodiment 1-3: a kind of anthraquinone finished product, it is prepared by following steps:

[0030] A. Take the anthraquinone raw material, raise the temperature to 40-50°C, add benzene until it just dissolves, heat filter to take the clear liquid, and concentrate the clear liquid to obtain an oil;

[0031] B. Take the oil obtained in step A, place it directly at -20~-10°C for quenching and directly add the water layer of -20~-10°C water / methyl tert-butyl ether saturated solution (including 0.1wt% to 0.5wt% of PAA), stirred, and a large amount of anthraquinone was precipitated, filtered and washed with water at 0 to 5°C to obtain the finished anthraquinone.

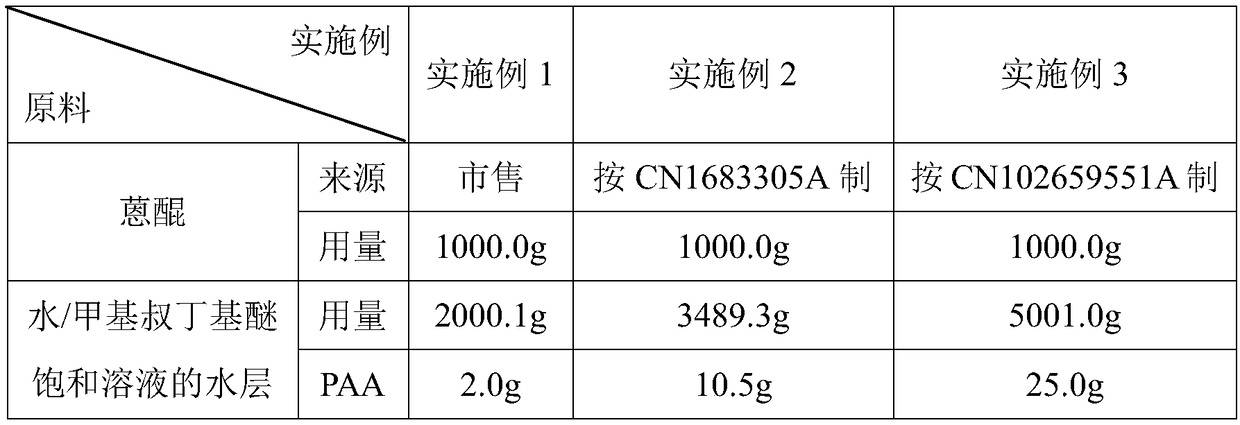

[0032] The raw material information of table 1 embodiment 1-3

[0033]

Embodiment 4

[0034] Embodiment 4: A finished product of anthraquinone, the difference from Embodiment 2 is that no PAA is added in Step B.

Embodiment 5

[0035] Example 5: A finished product of anthraquinone, the difference from Example 2 is that the temperature of the water used for washing in step B is 25-30°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com