High-temperature-resistant waterproof emulsified asphalt

A technology of emulsified asphalt and high temperature resistance, applied in asphalt coatings, fireproof coatings, coatings, etc., can solve problems such as waterproof layer damage, achieve the effects of improving bonding strength, high toughness, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

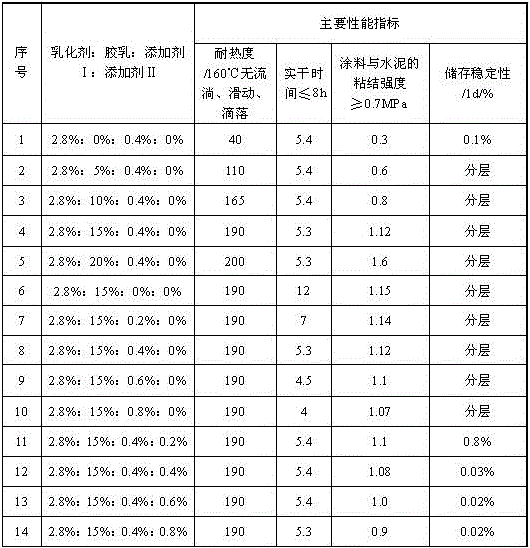

Examples

Embodiment 1

[0027] Example 1 High temperature-resistant waterproof emulsified asphalt, which is an emulsified asphalt with a pH value of 3 composed of raw materials in the following weight ratio (kg / kg): 2% emulsifier, 40% base asphalt, 10% latex, Additive I is 0.1%, additive II is 0.1%, and the balance is water.

[0028] in:

[0029] The emulsifier is made by mixing raw materials in the following weight ratio (kg / kg): aminated lignin 23%, aliphatic amine 35%, and the balance is water.

[0030] Aminated lignin refers to the product obtained by Mannich reaction of amine compounds, aldehyde compounds and lignin.

[0031] The number of carbon atoms of the aliphatic amine is 12, and the amine group is a primary or secondary amine.

[0032] The base asphalt is petroleum asphalt with an index penetration of 50.

[0033] The latex is mixed by the following weight ratio (kg / kg): cationic neoprene latex 24%, acrylic latex 23%, and the balance is water.

[0034] Additive I is made by mixing raw...

Embodiment 2

[0041] Example 2 High-temperature-resistant waterproof emulsified asphalt, which is emulsified asphalt with a pH value of 8 composed of raw materials in the following weight ratio (kg / kg): 4% emulsifier, 45% base asphalt, 20% latex, Additive I is 1%, additive II is 1%, and the balance is water.

[0042] in:

[0043] The emulsifier is made by mixing raw materials in the following weight ratio (kg / kg): aminated lignin 35%, aliphatic amine 23%, and the balance is water.

[0044] Aminated lignin refers to the product obtained by Mannich reaction of diethylenetriamine, formaldehyde, and broad-leaved pine lignin.

[0045] The number of carbon atoms in the aliphatic amine is 22, and the amine group is a primary or secondary amine.

[0046] The base asphalt is petroleum asphalt with an index penetration of 120.

[0047] Latex, additive I, additive II are the same as in Example 1.

[0048] The preparation method of the high temperature resistant waterproof emulsified asphalt compri...

Embodiment 3

[0053] Example 3 High temperature-resistant waterproof emulsified asphalt, which is emulsified asphalt with a pH value of 5.5 composed of the following weight ratios (kg / kg): 3% emulsifier, 42% base asphalt, 15% latex, Additive I is 0.5%, additive II is 0.5%, and the balance is water.

[0054] in:

[0055] The emulsifier is made by mixing raw materials in the following weight ratio (kg / kg): aminated lignin 29%, aliphatic amine 29%, and the balance is water.

[0056] Aminated lignin refers to the product obtained by Mannich reaction of triethylenetetramine, formaldehyde, and coniferous pine lignin.

[0057] The number of carbon atoms in the aliphatic amine is 17, and the amine group is a primary or secondary amine.

[0058] The base asphalt is petroleum asphalt with an index penetration of 85.

[0059] Latex, additive I, additive II are the same as in Example 1.

[0060] The preparation method of the high temperature resistant waterproof emulsified asphalt comprises the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com