Injection method and injection equipment of hydrogenation reactor sulfur replenishing agent in direct coal liquefaction process

A technology of hydrogenation reactor and direct coal liquefaction, applied in the petroleum industry, hydrocarbon oil cracking, hydrocarbon oil treatment and other directions, can solve the problems of high energy consumption and long sulfur replenishment process, and achieve the effect of reducing energy consumption and shortening the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

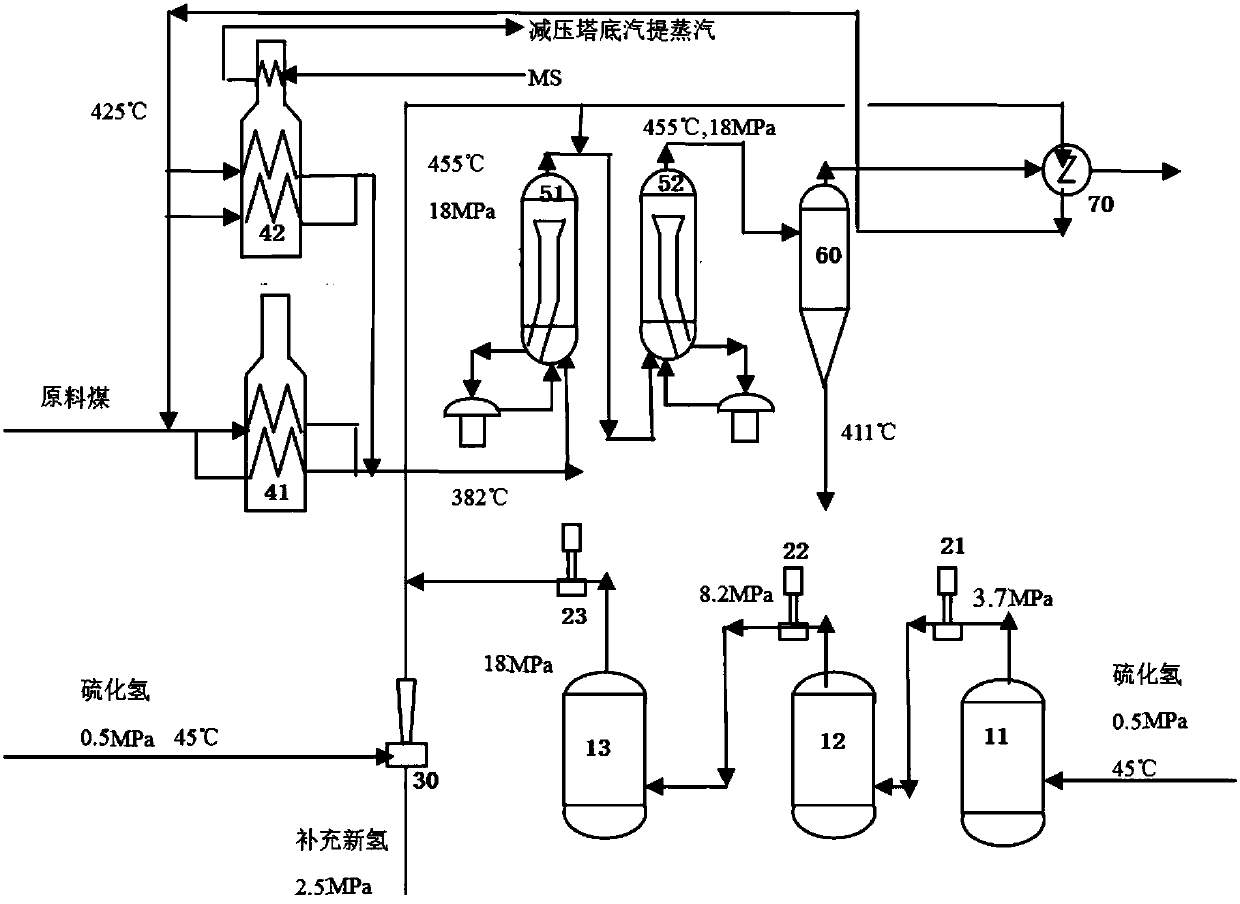

[0039] Such as figure 1 As shown, in the coal direct liquefaction technology, the hydrogen sulfide of the sewage stripping unit is 2300kg / h, the hydrogen sulfide of the desulfurization unit is 3600kg / h, and the hydrogen sulfide from coal hydrogenation with low methanol eluting sulfur is 2200kg / h, and the coal liquefaction is 100kg / h h, part of the hydrogen sulfide in a total of 8200kg / h, hydrogen sulfide at 0.5MPa and 45°C enters the primary buffer tank 11, is lifted by the primary compressor 21 to 3.7MPa and pressed into the secondary buffer tank 12, and then The secondary compressor 22 raises the hydrogen sulfide pressure in the secondary buffer tank 12 to 8.2 MPa and presses it into the tertiary buffer tank 13, and then the tertiary compressor 23 raises the hydrogen sulfide pressure in the tertiary buffer tank 13 to 8.2 MPa. 18Mp is injected into the coal liquefaction primary hydrogenation reactor 51 and the secondary hydrogenation reactor 52 to meet the required partial pr...

Embodiment 2

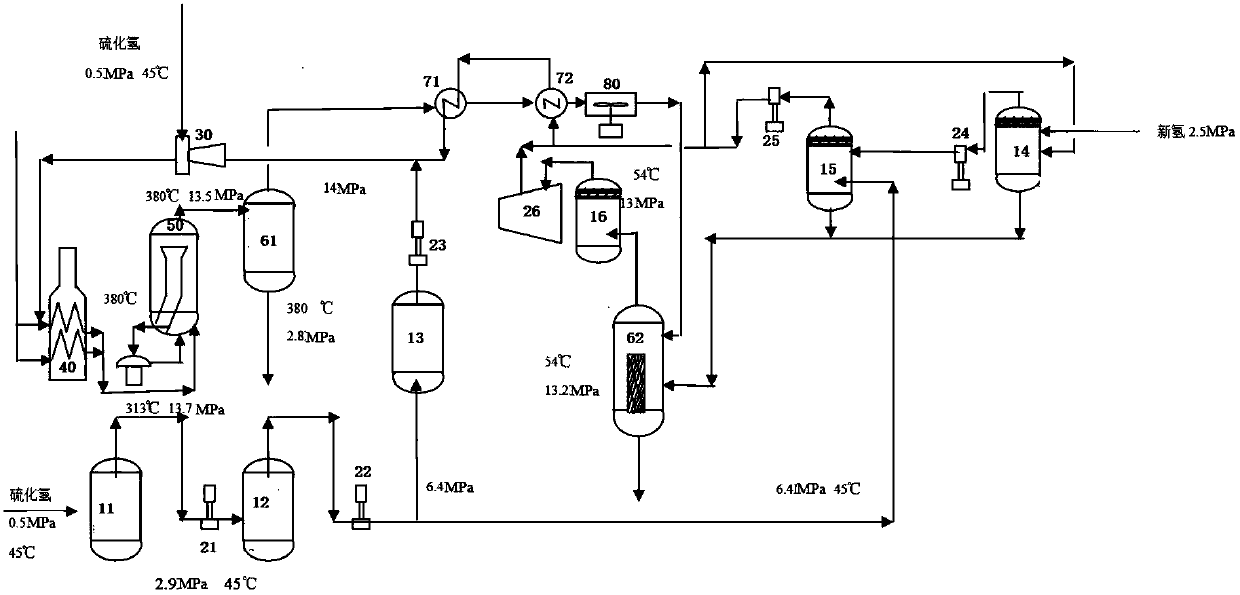

[0041] Such as figure 2 As shown, in the hydrogenation stabilization technology, the hydrogen sulfide of the sewage stripping unit is 2300kg / h, the hydrogen sulfide of the desulfurization unit is 3600kg / h, and the hydrogen sulfide from coal hydrogenation with low methanol eluting sulfur is 2200kg / h, and the coal liquefaction is 100kg / h h, part of the hydrogen sulfide in a total of 8200kg / h, hydrogen sulfide at 0.5MPa and 45°C enters the primary buffer tank 11, is lifted by the primary compressor 21 to 2.9MPa and pressed into the secondary buffer tank 12, and then The secondary compressor 22 raises the hydrogen sulfide pressure in the secondary buffer tank 12 to 6.4MPa and presses it into the tertiary buffer tank 13, and then the tertiary compressor 23 raises the hydrogen sulfide pressure in the tertiary buffer tank 13 to 6.4 MPa. 14Mp is injected in the hydrogenation stabilization reactor 50; perhaps hydrogen sulfide in the secondary buffer tank 12 is pressed into the second ...

Embodiment 3

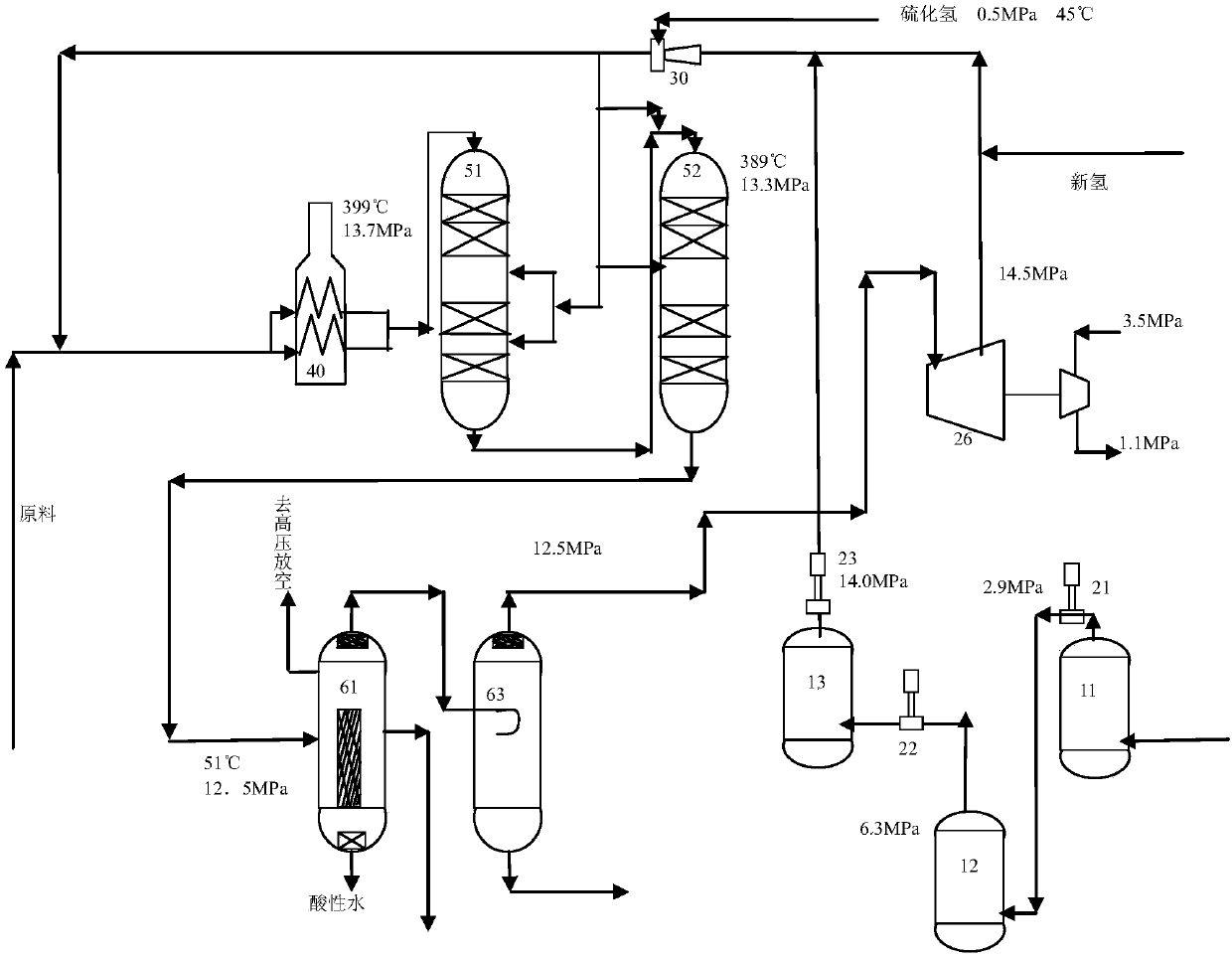

[0043] Such as image 3 As shown, in the hydrogenation upgrading technology, the hydrogen sulfide of the sewage stripping unit is 2300kg / h, the hydrogen sulfide of the desulfurization unit is 3600kg / h, and the hydrogen sulfide from coal hydrogenation with low methanol eluting sulfur is 2200kg / h, and the coal liquefaction is 100kg / h, part of the hydrogen sulfide in a total of 8200kg / h, hydrogen sulfide at 0.5MPa and 45°C enters the primary buffer tank 11, is lifted by the primary compressor 21 to 2.9MPa and pressed into the secondary buffer tank 12, and then The hydrogen sulfide pressure in the secondary buffer tank 12 is raised to 6.3 MPa by the secondary compressor 22 and pressed into the tertiary buffer tank 13, and then the hydrogen sulfide pressure in the tertiary buffer tank 13 is raised by the tertiary compressor 23 to 14Mp into the primary hydrogenation reactor 51 and the secondary hydrogenation reactor 52 of hydrogenation upgrading; in order to ensure that the concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com