Low-rank coal low-temperature pyrolysis tar gas recycling equipment

A technology of low-temperature pyrolysis and recovery equipment, which is used in gas dust removal, petroleum industry, combustible gas purification, etc. the effect of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

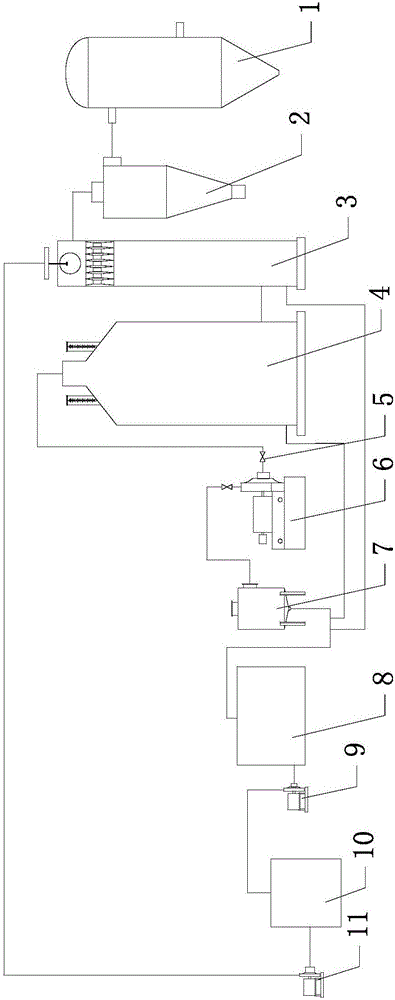

[0009] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0010] As shown in the figure, a low-rank coal low-temperature pyrolysis tar gas recovery equipment includes a high-temperature electrostatic precipitator 1, a high-temperature cyclone separator 2, a cooling tower 3, an electric tar catcher 4, and The induced draft fan 6, the rotary collector 7, the tar collection pool 8, the tar delivery pump 9, the tar storage tank 10 and the tar cooling pump 11 are provided with a dust collector inlet on the right side of the high temperature electrostatic precipitator 1, and the high temperature electrostatic precipitator 1 The outlet of the dust collector is connected with the separator inlet of the high-temperature cyclone separator 2 through the pipeline, and the separator outlet of the high-temperature cyclone sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com