Hemp and long-staple cotton blended 80-count yarn and production method

A production method, the technology of long-staple cotton, which is applied in the blending of hemp and long-staple cotton 80-count yarn and its production field, can solve the problems of unguaranteed yarn quality, high strength of hemp fiber, and great difficulty in textile processing, and achieve The effect of excellent performance, good softness and comfort, and excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of hemp and long-staple cotton blending 80 count yarns, it is produced by following each procedure:

[0036] 1) Blending process

[0037] Because the hemp fiber is relatively rigid, it is easy to be damaged when it comes into contact with the machine parts. In order to reduce the friction factor between the hemp and the machine parts, it is necessary to pretreat the hemp. Use: soft sesame oil agent FD- ZY06A, the soft sesame oil agent FD-ZY06B accounting for 0.4% of the hemp weight, mixed with water accounting for 4.8% of the hemp weight is configured as a hemp pretreatment oil, and then the pretreatment oil is evenly sprayed on the hemp fiber, and then Seal it with a cover cloth and place it in the cleaning round table for 24 hours, then weigh the long-staple cotton according to the weight ratio of hemp and long-staple cotton 40:60, mix the long-staple cotton and hemp fiber evenly in the cleaning round table, and Prepare for flower cleaning process.

[0038] 2...

Embodiment 2

[0060] The parameters of each process in Example 1 are consistent, except that the weight ratio of hemp to long-staple cotton is 45:60.

Embodiment 3

[0062] The parameters of each process in Example 1 are consistent, except that the weight ratio of hemp to long-staple cotton is 50:60.

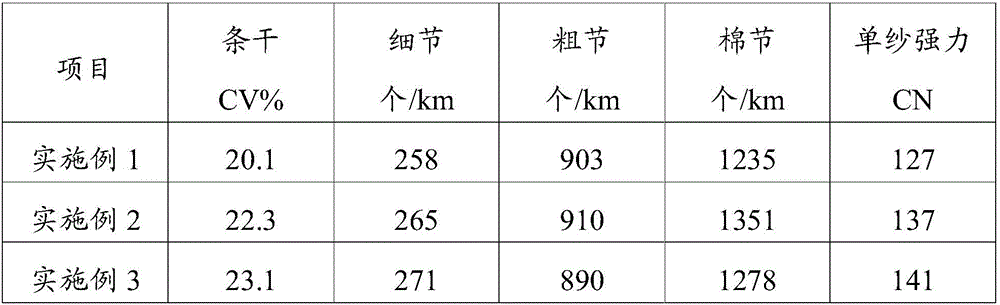

[0063] After testing, the physical parameters of 80 counts of hemp and long-staple cotton blended yarns produced in Examples 1 to 3 are shown in the table below:

[0064]

[0065] It can be seen from the data in the above table that the production method provided by the present invention can produce 80 count yarns with better quality and more stable performance of the product, and the 80 count yarns can be used in the production of high-grade clothing fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com