Sandstone reservoir self-diverting acidizing method

A self-steering and acid-steering technology, which is applied to chemical instruments and methods, mining fluids, earthwork drilling, etc., can solve the problems of high construction cost, poor acidizing effect of heterogeneous sandstone reservoirs, and low content of soluble matter. Achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Taking the indoor simulation experiment of cores in Bozhong SZ36-1 oilfield of CNOOC as an example, the detailed description will be given.

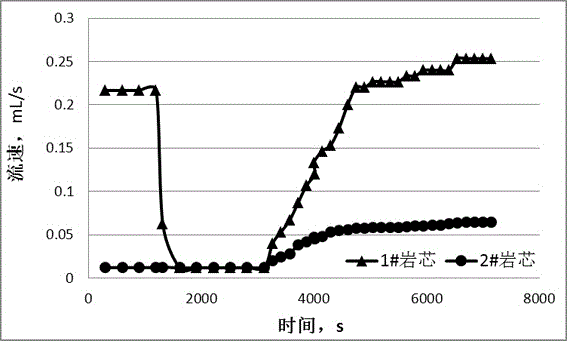

[0034] Flow experiments using parallel dual cores with different permeability are used to simulate the fluid permeability in the reservoir due to the heterogeneity of the reservoir under formation conditions. 1# core: core length 7cm, diameter 2.54cm, porosity 27.5%, permeability 683×10 -3 μm 2 , 2# core: core length 7cm, diameter 2.54cm, porosity 9.6%, permeability 38×10 -3 μm 2 . To simulate the reservoir conditions, the diversion acidizing flow experiment was carried out at a temperature of 60°C and a confining pressure of 1 MPa, according to the principle of "injecting base fluid→injecting diverting acid→injecting treatment fluid→injecting postfluid→injecting replacement fluid→injecting base fluid" Injection sequence, simulating the flow process of the well fluid entering the reservoir during the diversion ac...

Embodiment 2

[0043] Embodiment 2: Taking the indoor simulation experiment of cores in Bozhong SZ36-1 oilfield of CNOOC as an example, the detailed description will be given.

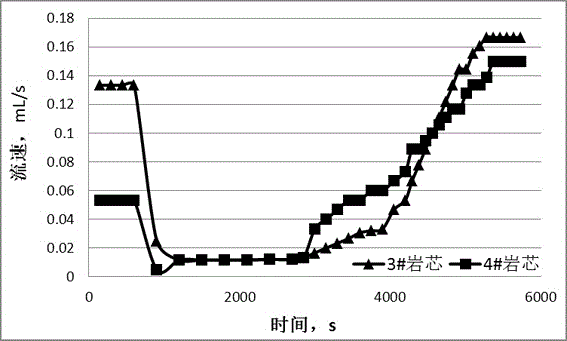

[0044] Flow experiments using parallel dual cores with different permeability are used to simulate the fluid permeability in the reservoir due to the heterogeneity of the reservoir under formation conditions. 3# core: core length 7cm, diameter 2.54cm, porosity 21.5%, permeability 487×10 -3 μm 2 , 4# core: core length 7cm, diameter 2.54cm, porosity 13.6%, permeability 98×10 -3 μm 2 . To simulate the reservoir conditions, the diversion acidizing flow experiment was carried out at a temperature of 90°C and a confining pressure of 1 MPa, according to the principle of "injecting base fluid→injecting diverting acid→injecting treatment fluid→injecting postfluid→injecting displacement fluid→injecting base fluid" Injection sequence, simulating the flow process of the well fluid entering the reservoir during the diversion ...

Embodiment 3

[0079] Example 3: Caofeidian 11-6 Oilfield D16H well, field operation of diverting acid in detail.

[0080] Well D16H is a horizontal well, which was put into production on March 15, 2008. The length of the horizontal section is 202m, and the effective thickness of the average production layer is 8m. For the uniform distribution of layers, it is necessary to use the way of turning to achieve uniform distribution of acid. The sequence of construction operations is as follows: injecting pre-fluid → injecting treatment fluid → injecting post-fluid → injecting pre-fluid → injecting treatment fluid → injecting post-fluid → injecting pre-fluid → injecting treatment fluid → injecting post-fluid → injecting replacement fluid .

[0081] D16H well diversion diversion acidification of all the weight percentage of each well fluid:

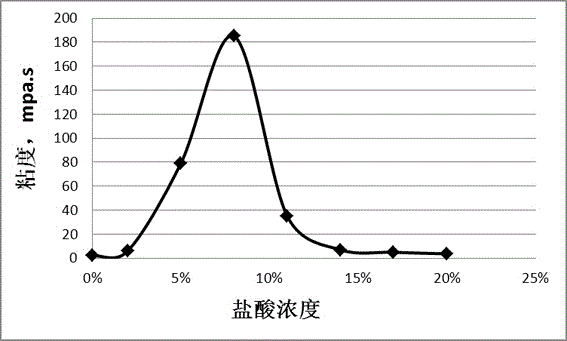

[0082] Steering acid (preflux): 13% hydrochloric acid, 6% diverting agent, 1% corrosion inhibitor, 1% iron ion stabilizer, 1% clay stabilizer, 1% drainage a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com