Hall thruster cooling bracket

A technology of Hall thruster and heat dissipation bracket, which is applied to thrust reversers, machines/engines, utilizing plasma, etc., can solve the problems of overall Hall thruster, overheating, etc., and achieve the effect of increasing space radiation heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

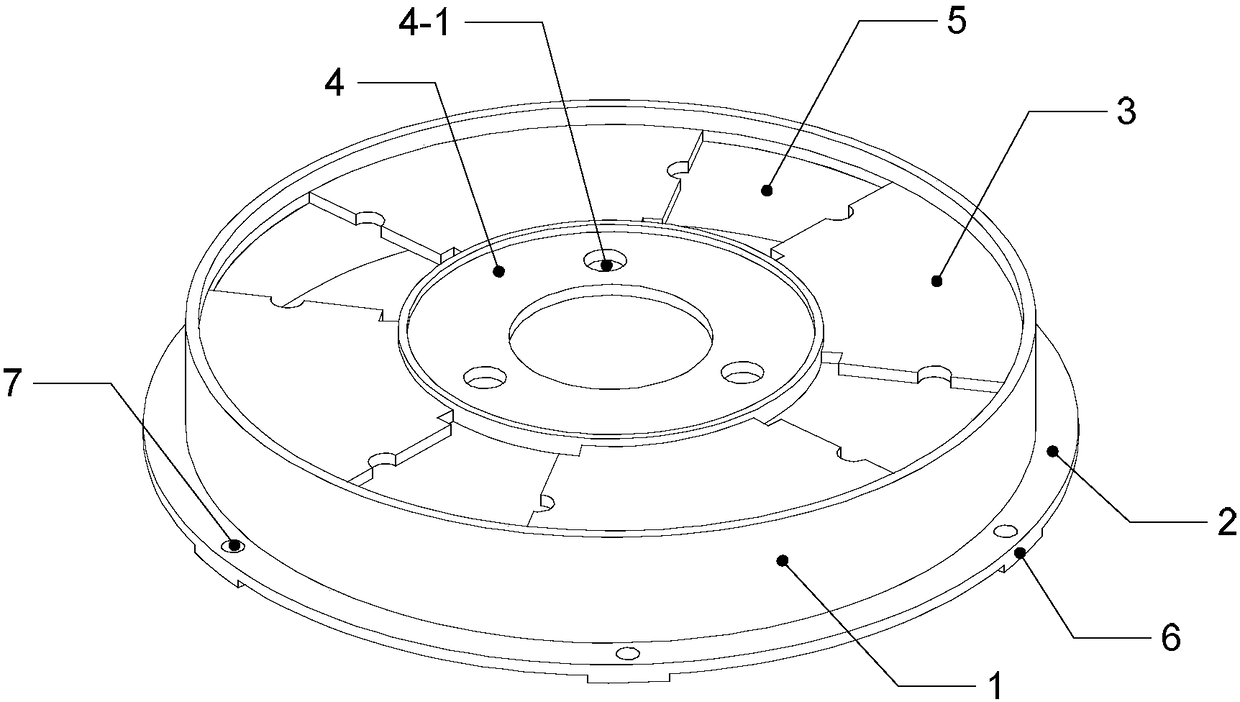

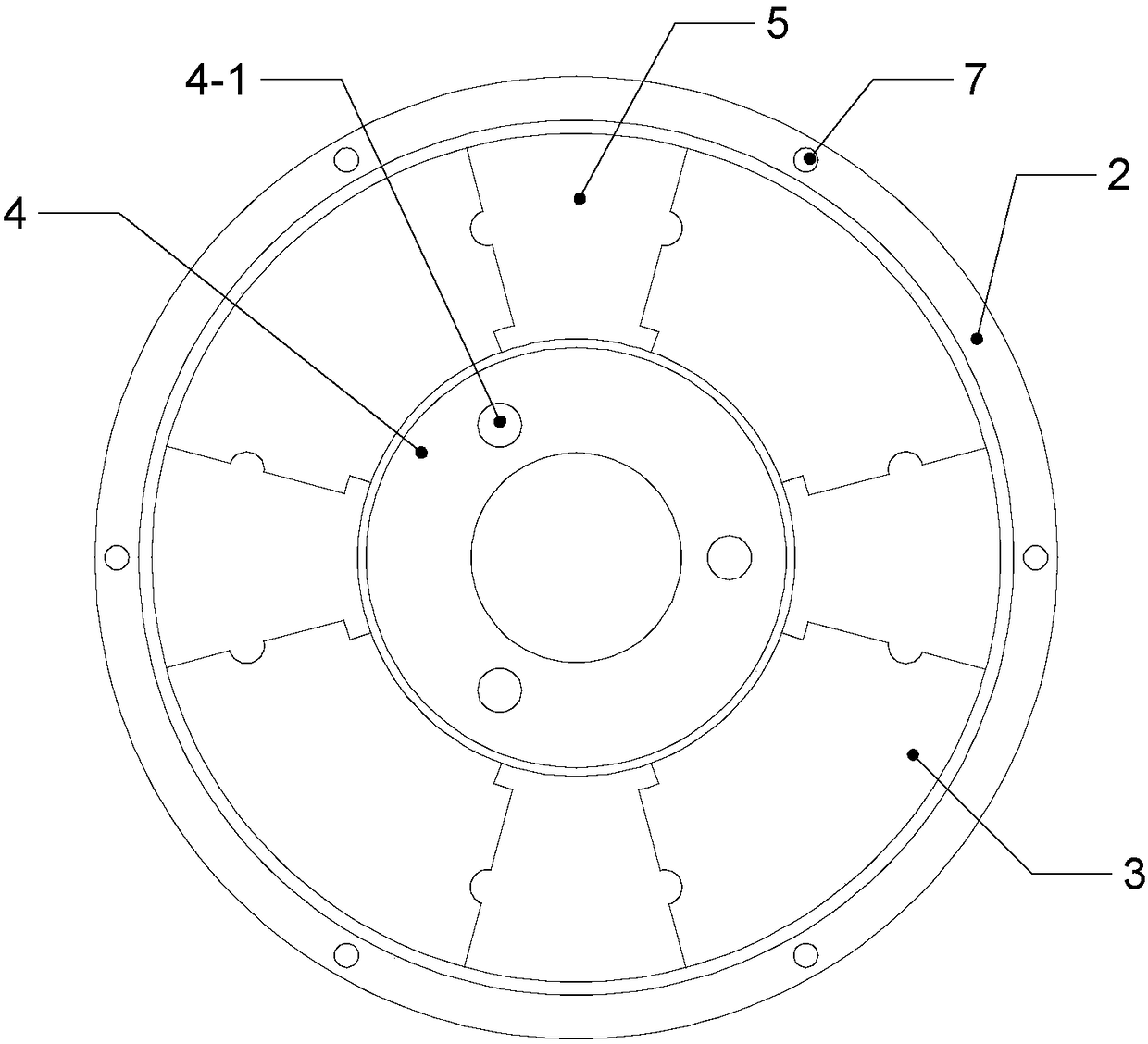

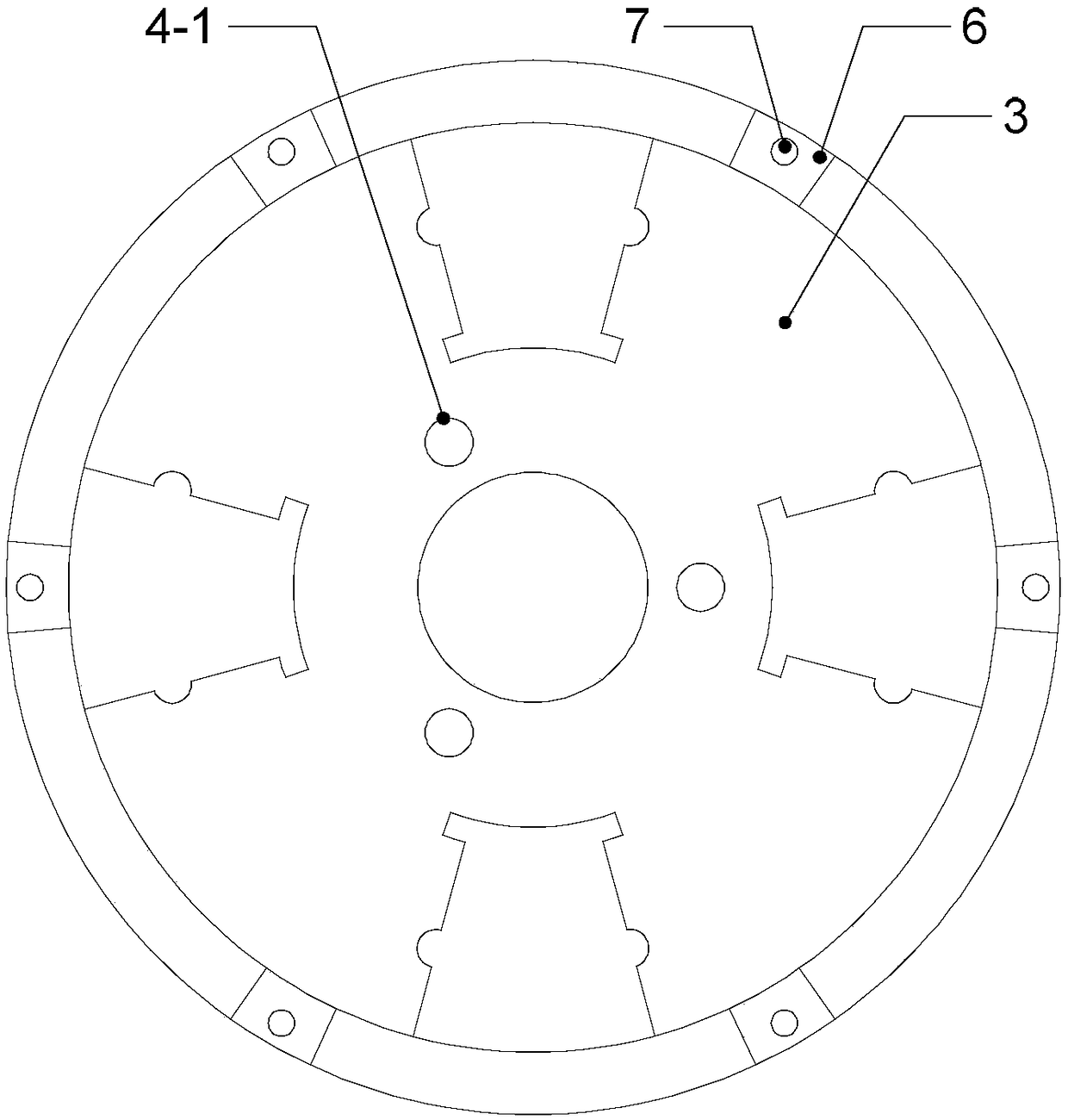

[0021] Specific implementation mode one: the following combination Figure 1 to Figure 4 To illustrate this embodiment, the Hall thruster cooling bracket described in this embodiment can be found in figure 1 As shown, this embodiment adopts an integrated processing method, and a whole piece of material is directly processed to ensure that the overall structure has a small thermal resistance.

[0022] In this embodiment, the material used for the cooling support structure of the Hall thruster is an aluminum alloy with high thermal conductivity and strong anti-sputtering ability. The thermal conductivity of the aluminum alloy is generally 210W / (m·K).

[0023] During the installation and use of the heat dissipation support of this embodiment, the heat dissipation support contacts with other parts at two parts, one is that it acts as a ceramic support, and the ceramic discharge channel is fixed on the discharge channel installation ring surface 4 in the middle; the other is It it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com