Interdigital electrode with porous metal modified surface and preparation method and application thereof

A technology of porous metal and modified surface, applied in the field of sensors, can solve the problems of difficulty in significantly improving the sensitivity of the sensor, increasing the sensitive components on the interdigital electrodes, and insignificant improvement in the sensitivity of the sensor, so as to improve the detection sensitivity, increase the load, and the bonding strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

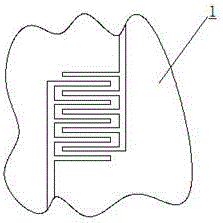

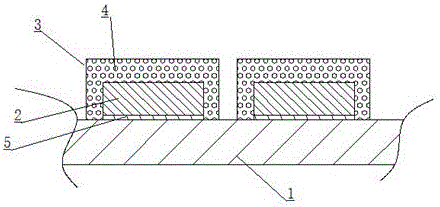

[0038] This embodiment provides an interdigitated electrode with a porous metal modified surface, such as figure 1 and figure 2 , comprising an insulating base 1, an electrode layer 2 disposed on the surface of the insulating base 1; a porous metal layer 3 is provided on the reaction surface of the electrode layer 2, and a reaction hole 4 is arranged in the porous metal layer; the reaction holes communicate with each other.

[0039] There is also a transition metal layer 5 between the electrode layer and the insulating base layer, the thickness of which is 60A; the transition metal layer is a Ti layer.

[0040] In this embodiment, the insulating base layer is ceramic.

[0041] Further, in this embodiment, the diameter of the reaction hole is 60-70 nm; the surface porosity of the porous metal layer is 20%.

[0042] Furthermore, the thickness of the porous metal layer is 25 μm.

[0043] The above-mentioned electrode layer is composed of Ag simple substance.

[0044] Prefera...

Embodiment 2

[0046] This embodiment provides an interdigitated electrode with a porous metal modified surface, such as figure 1 and figure 2 , comprising an insulating base, 1. An electrode layer 2 arranged on the surface of the insulating base; the reaction surface of the electrode layer is provided with a porous metal layer 3, and the porous metal layer 3 is provided with a reaction hole 4; the reaction holes communicate with each other. In this embodiment, the insulating base is made of prepreg.

[0047] Further, in this embodiment, the diameter of the above-mentioned reaction pores is 70-80 nm; the surface porosity of the porous metal layer is 35%.

[0048] Furthermore, the thickness of the porous metal layer is 30 μm.

[0049]A transition metal layer 5 with a thickness of 100 Å is also provided between the electrode layer and the insulating base layer; the transition metal layer is a W layer.

[0050] The above-mentioned electrode layer is composed of a copper layer and a gold lay...

Embodiment 3

[0053] This embodiment provides an interdigitated electrode with a porous metal modified surface, such as figure 1 and figure 2 , including an insulating base, 1. An electrode layer 2 arranged on the surface of the insulating base; a porous metal layer 3 is provided on the reaction surface of the electrode layer, and 4 reaction holes are arranged in the porous metal layer; the reaction holes communicate with each other.

[0054] In this embodiment, the insulating base is made of glass.

[0055] Further, in this embodiment, the diameter of the above-mentioned reaction pores is 70-90 nm; the surface porosity of the porous metal layer is 20%.

[0056] Furthermore, the thickness of the porous metal layer is 50 μm.

[0057] Preferably, the above-mentioned porous metal layer is made of Cu metal. In this embodiment, the above-mentioned electrode layer may be made of copper.

[0058] There is also a transition metal layer 5 between the electrode layer and the insulating base laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com