Motor servo system self-adaptive robustness control method including input interval

An adaptive robust, servo system technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as large online calculation time, initial condition limit, large calculation amount, etc., to improve control performance , the effect of counteracting the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

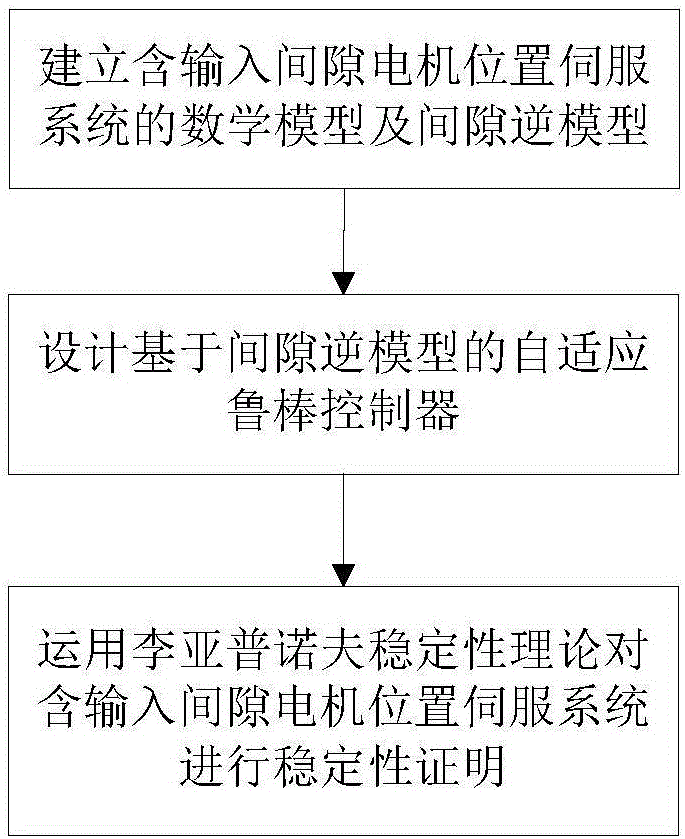

Method used

Image

Examples

Embodiment

[0070] The parameter values of the motor servo system are as follows:

[0071] J=0.01kg·m 2 , B=5N·m·rad-1·s -1 , m=1, B r = 1, B l = 1;

[0072] Now compare the following controllers:

[0073] (1) controller parameter k of the present invention's design 1 =800,k s1 =2000, Γ=diag{100,100}.

[0074] (2) PID controller parameter is k p =20,k i =650,k d = 0.1.

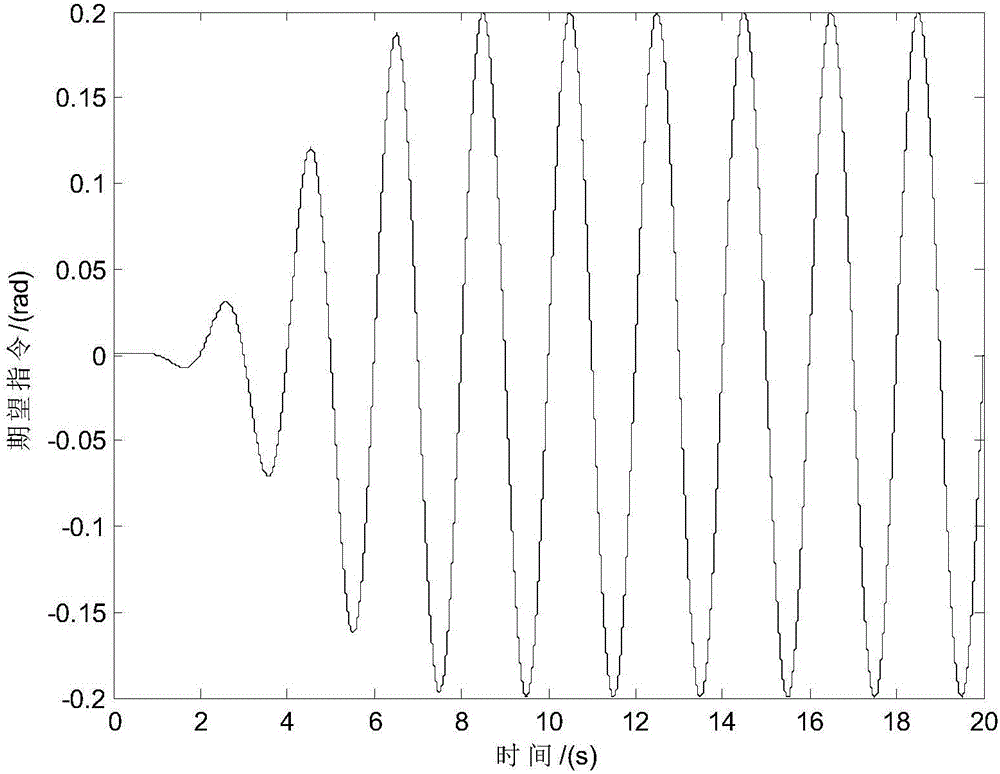

[0075] Position angle input signal

[0076] The effect of the control law:

[0077] figure 2 It is a schematic diagram of two kinds of controller trajectory tracking instructions.

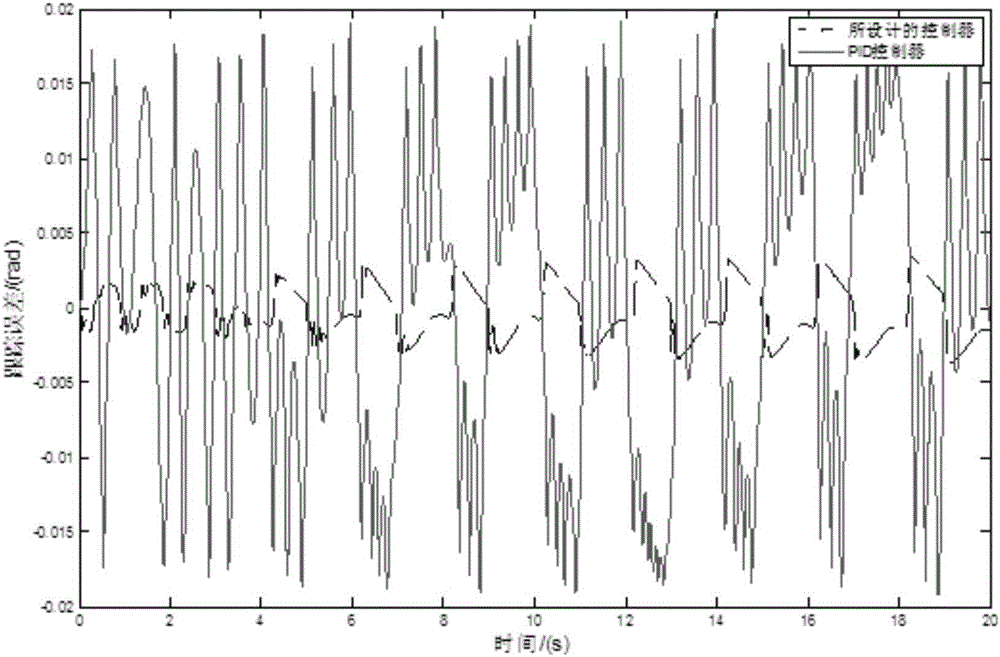

[0078] image 3 It is a curve graph of the tracking error of the two controllers changing with time, and it can be seen that the controller designed by the present invention is obviously better than the PID controller.

[0079] Figure 4 It is a curve diagram of the control input of the controller designed by the present invention changing with time. It can be seen from the figure that the control input signal obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com