Preparation method and application of flower-shaped composite material formed by carbon plates in which cobaltosic oxide is embedded in hollow nano sphere mode

A technology of cobalt tetroxide nanometer and composite material, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low specific capacity and short cycle life, achieve high specific capacity and increase conductivity , the effect of a good design strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

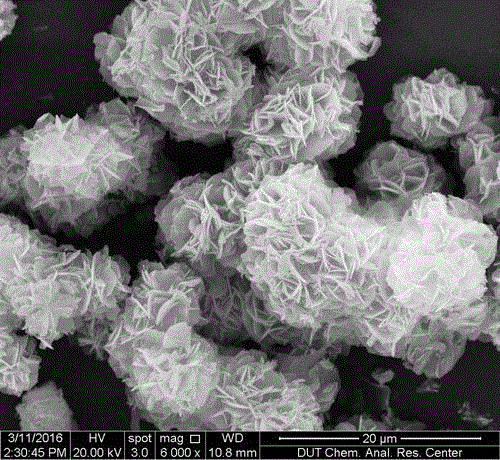

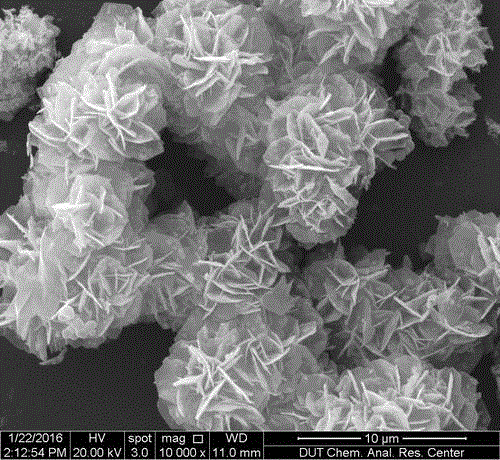

[0024] (1) 1 g of cobalt sulfate heptahydrate, 0.7 g of glucose and 0.7 g of hexamethylenetetramine were dissolved in 40 mL of deionized water to obtain a transparent liquid;

[0025] (2) The transparent liquid prepared in step (1) was encapsulated in a PTFE-lined 50 mL autoclave, and then the autoclave was placed in an oven, and reacted at 180 °C for 24 h to obtain a flower-like microstructure. Precursor;

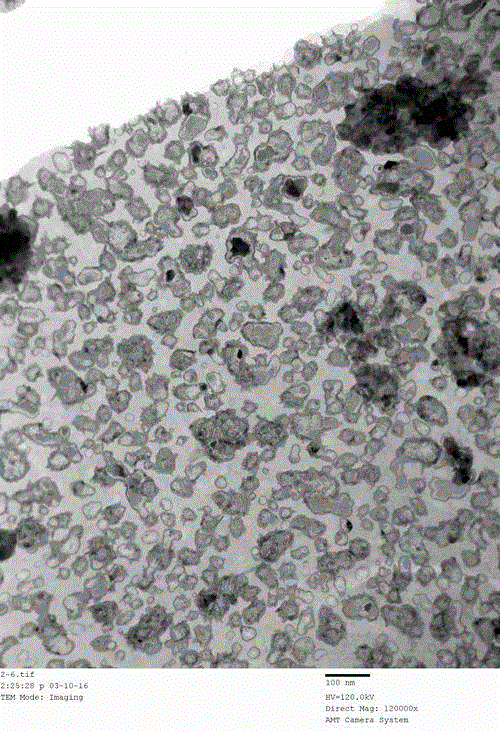

[0026] (3) Heat the organic precursor prepared in step (2) to 300 °C at a heating rate of 2 °C / min in nitrogen, keep the temperature for 2 h, then raise the temperature to 800 °C at a heating rate of 5 °C / min, and anneal for 2 h, obtain the composite material of reduced cobalt oxide and carbon;

[0027] (4) The material prepared in step (3) was heated to 300 °C in air at a heating rate of 5 °C / min, and kept at a constant temperature for 2 h to obtain the target product, a composite material of cobalt trioxide nanohollow spheres and carbon.

Embodiment 2

[0029] (1) 1.04 g of cobalt nitrate hexahydrate, 0.7 g of glucose and 0.7 g of hexamethylenetetramine were dissolved in 40 mL of deionized water, and electromagnetically stirred to obtain a transparent liquid;

[0030] (2) The transparent liquid prepared in step (1) was packaged in a 50 mL polytetrafluoro-lined autoclave, and then the autoclave was placed in an oven and reacted at 180 °C for 24 h to obtain a flower-like microstructure. Precursor;

[0031] (3) Heat the organic precursor prepared in step (2) to 300 °C at a heating rate of 2 °C / min in nitrogen, keep the temperature for 2 h, then raise the temperature to 800 °C at a heating rate of 5 °C / min, and anneal for 2 h, obtain the composite material of reduced cobalt and carbon;

[0032] (4) The material prepared in step (3) was heated to 300 °C in air at a heating rate of 5 °C / min, and kept at a constant temperature for 2 h to obtain the target product, a composite material of cobalt trioxide nanohollow spheres and carbo...

Embodiment 3

[0034] (1) 1.0 g of cobalt sulfate heptahydrate, 0.7 g of fructose and 0.7 g of hexamethylenetetramine were dissolved in 40 mL of deionized water, and electromagnetically stirred to obtain a transparent liquid;

[0035] (2) The transparent liquid prepared in step (1) was packaged in a 50 mL polytetrafluoro-lined autoclave, and then the autoclave was placed in an oven and reacted at 180 °C for 24 h to obtain a flower-like microstructure. Precursor;

[0036] (3) Heat the precursor prepared in step (2) to 300 °C at a heating rate of 2 °C / min in nitrogen, keep the temperature for 2 h, then raise the temperature to 800 °C at a heating rate of 5 °C / min, and anneal for 2 h. Obtain the composite material of reduced cobalt and carbon;

[0037] (4) The material prepared in step (3) was heated to 300 °C in air at a heating rate of 5 °C / min, and kept at a constant temperature for 2 h to obtain the target product, a composite material of cobalt trioxide nanohollow spheres and carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com