Lead-saving butt welding lead part and butt welding method thereof

A technology for welding parts and lead parts, applied in the field of lead-acid batteries, which can solve the problems of high cost, low bulk density and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

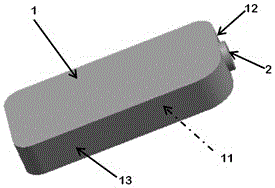

[0032] refer to figure 1 , is a lead-butt soldering part provided by this application (applicable to 1×6 structural battery). The butt-welding lead part includes a busbar 1 and a butt-welding piece 2, and the busbar 1 includes a casting welding surface 11 of an electrode group lug, a side part 12 and two pressing surfaces 13 of welding arms. The butt weldment 2 is connected to the side part 12 of the bus bar and has a small volume. It is in the shape of a cylinder, a round table, a sphere or an ellipsoid. The butt weldment 2 is a place where the butt weld is directly contacted by the extrusion of the welding arm and then energized. , at the end of welding it is all extruded in the slotted hole.

[0033] The butt weldment 2 in this example is a cylinder.

[0034] The butt welding method in this example is: the welding arm of the butt welding machine clamps the two welding arm pressing surfaces 13 on the side of the bus bar, and then squeezes the butt welding parts 2 in a hori...

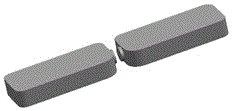

Embodiment 2

[0036] On the basis of Embodiment 1, this embodiment provides a kind of accumulator that contains this butt-welding lead parts, comprises butt-welding lead parts, tank body partition wall 3 and pole group 4, the tank body partition wall 3 and the pole group 4 in this example The pole group 4 is well known to those skilled in the art, and will not be repeated here.

[0037] The battery cells are separated by the tank body partition wall 3, wherein holes are punched on the tank body partition wall 3, so that the adjacent cells can be welded with lead parts for butt welding. Because it reduces the height and occupied space of the welding parts, it improves the energy density of the battery; at the same time, because the current transmission path is reduced, it can reduce the internal resistance of the battery; at the same time, it saves lead consumption and reduces production costs.

[0038] The butt welding method in this example is:

[0039] 1) Use the welding arm of the wel...

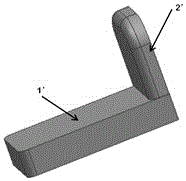

Embodiment 3

[0046] On the basis of Embodiment 1, this embodiment provides a kind of accumulator that contains this butt-welding lead parts, comprises butt-welding lead parts, tank body partition wall 3 and pole group 4, the tank body partition wall 3 and the pole group 4 in this example The pole group 4 is well known to those skilled in the art, and will not be repeated here.

[0047] The battery cells are separated by the tank body partition wall 3, wherein holes are punched on the tank body partition wall 3, so that the adjacent cells can be welded with lead parts for butt welding. Because it reduces the height and occupied space of the welding parts, it improves the energy density of the battery; at the same time, because the current transmission path is reduced, it can reduce the internal resistance of the battery; at the same time, it saves lead consumption and reduces production costs.

[0048] The butt welding method in this example is:

[0049]1) Use the welding arm of the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com