Diamond grinding material arranging system

A diamond and abrasive technology, which is applied in the field of diamond abrasive arrangement system, can solve the problems of reduced arrangement accuracy, low production efficiency, and decreased cutting efficiency of saw blades, and achieves improved arrangement accuracy, low equipment cost, and omission of vibrator Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The diamond abrasive arrangement system described in the present invention will be further elaborated below in conjunction with specific examples, to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solutions of the present invention; it should be pointed out that The descriptions of structures, functions, materials, etc. in the embodiments are all illustrative, and not intended to limit the protection scope of the invention.

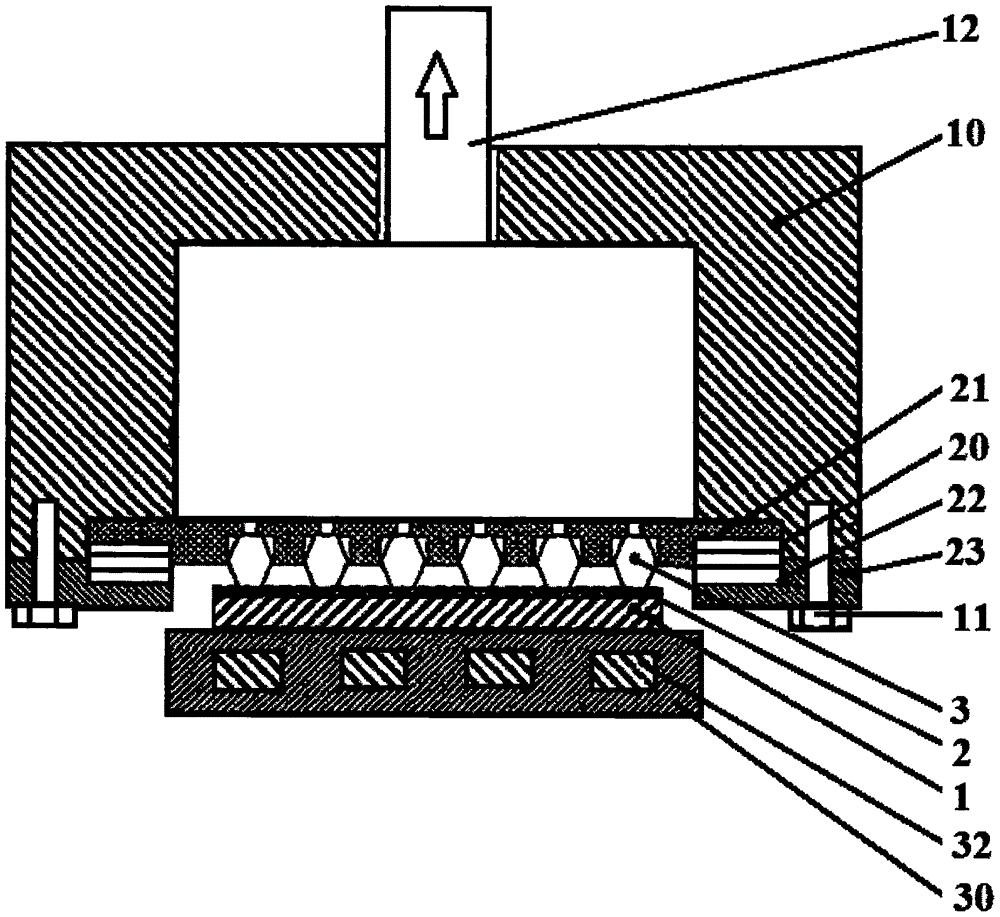

[0025] Such as figure 1 As shown, the diamond abrasive arrangement system of the present invention includes a reclaimer 10 and a workbench 30, the reclaimer 10 includes a cavity, and the upper part of the cavity is connected to a vacuum device 12 through an air suction port, and the cavity The lower part of the frame is fixedly equipped with an arrangement formwork assembly 20 . The arrangement template assembly 20 includes a ferromagnetic arrangement orifice plate 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com