Method for preparing waterborne polyurethane using vegetable oil based cardanol as raw material

A water-based polyurethane and vegetable oil-based technology, which is applied in the field of preparing water-based polyurethane, can solve the problems of polluting the environment and endangering human health, and achieves the effects of good dispersion stability, easy operation, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

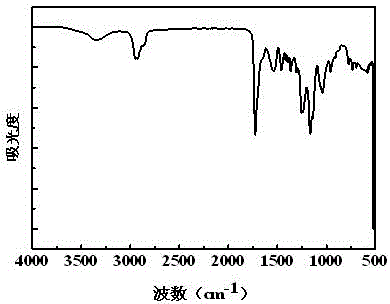

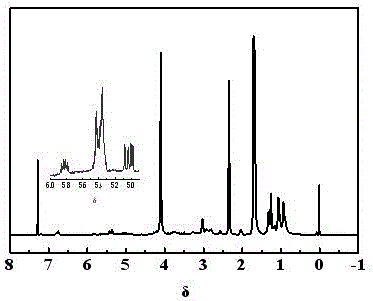

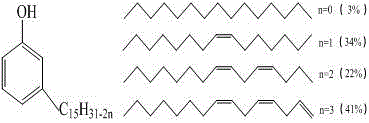

Method used

Image

Examples

Embodiment 1

[0023] Follow the steps below to prepare cardanol-based waterborne polyurethane:

[0024] (1) Add 100g (0.33mol) of cardanol and 0.1g of zinc chloride into a 100mL three-neck flask equipped with a condenser, an electric stirrer and filled with nitrogen, heat to 95°C, and add 46g (0.5mol) dropwise within 30 minutes Epichlorohydrin, react for 2~3h; add 16g (0.4mol) sodium hydroxide dropwise within 40min, raise the temperature to 100°C and react for 2h, transfer the above product to a separatory funnel, wash with water until neutral, separate the organic layer and dry Filtrate, and rotate the resulting filtrate at 90°C and -0.1MPa to remove excess epichlorohydrin to obtain cardanol glycidyl ether.

[0025] (2) Add 40g of cardanol glycidyl ether and 9g of sulfuric acid into a 250mL three-neck flask equipped with a condenser, an electric stirrer and filled with nitrogen, raise the temperature to 100°C, react for 12h, cool to room temperature, wash with water until neutral, separate...

Embodiment 2

[0029] Follow the steps below to prepare cardanol-based waterborne polyurethane:

[0030] (1) Add 100g (0.33mol) cardanol and 0.12g zinc chloride to a 100mL three-neck flask equipped with a condenser, an electric stirrer and filled with nitrogen, heat to 100°C, and add 50.6g (0.55mol) dropwise within 30 minutes ) epichlorohydrin, react for 2~3h; add 16.8g (0.42mol) sodium hydroxide dropwise within 40min, raise the temperature to 100°C for 2h, transfer the above product to a separatory funnel, wash with water until neutral, and separate the organic layer drying and filtering, and the resulting filtrate was vacuum rotary evaporated to remove excess epichlorohydrin to obtain cardanol glycidyl ether.

[0031] (2) Add 40g of cardanol glycidyl ether and 10g of sulfuric acid into a 250mL three-neck flask equipped with a condenser, an electric stirrer and filled with nitrogen, raise the temperature to 105°C, react for 13h, cool to room temperature, wash with water until neutral, separ...

Embodiment 3

[0035] Follow the steps below to prepare cardanol-based waterborne polyurethane:

[0036] (1) Add 100g (0.33mol) of cardanol and 0.13g of zinc chloride into a 100mL three-neck flask equipped with a condenser, an electric stirrer and filled with nitrogen, heat to 100°C, and add 55.5g (0.6mol) of ) epichlorohydrin, react for 2~3h; add 19.6g (0.49mol) sodium hydroxide dropwise within 40min, raise the temperature to 100°C for 2h, transfer the above product to a separatory funnel, wash with water until neutral, and separate the organic layer drying and filtering, and the resulting filtrate was vacuum rotary evaporated to remove excess epichlorohydrin to obtain cardanol glycidyl ether.

[0037](2) Add 40g of cardanol glycidyl ether and 8g of sulfuric acid into a 250mL three-neck flask equipped with a condenser, an electric stirrer and filled with nitrogen, raise the temperature to 105°C, react for 13h, cool to room temperature, wash with water until neutral, separate Add anhydrous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com