li-based + or la 3+ Ion-exchange Y-type zeolite ammonia sensor

An ammonia sensor and ion exchange technology, applied in the direction of material resistance, etc., can solve the problems of inoperable detection performance, increased sensor energy consumption, waste, etc., and achieve low power consumption, low operating temperature, and stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

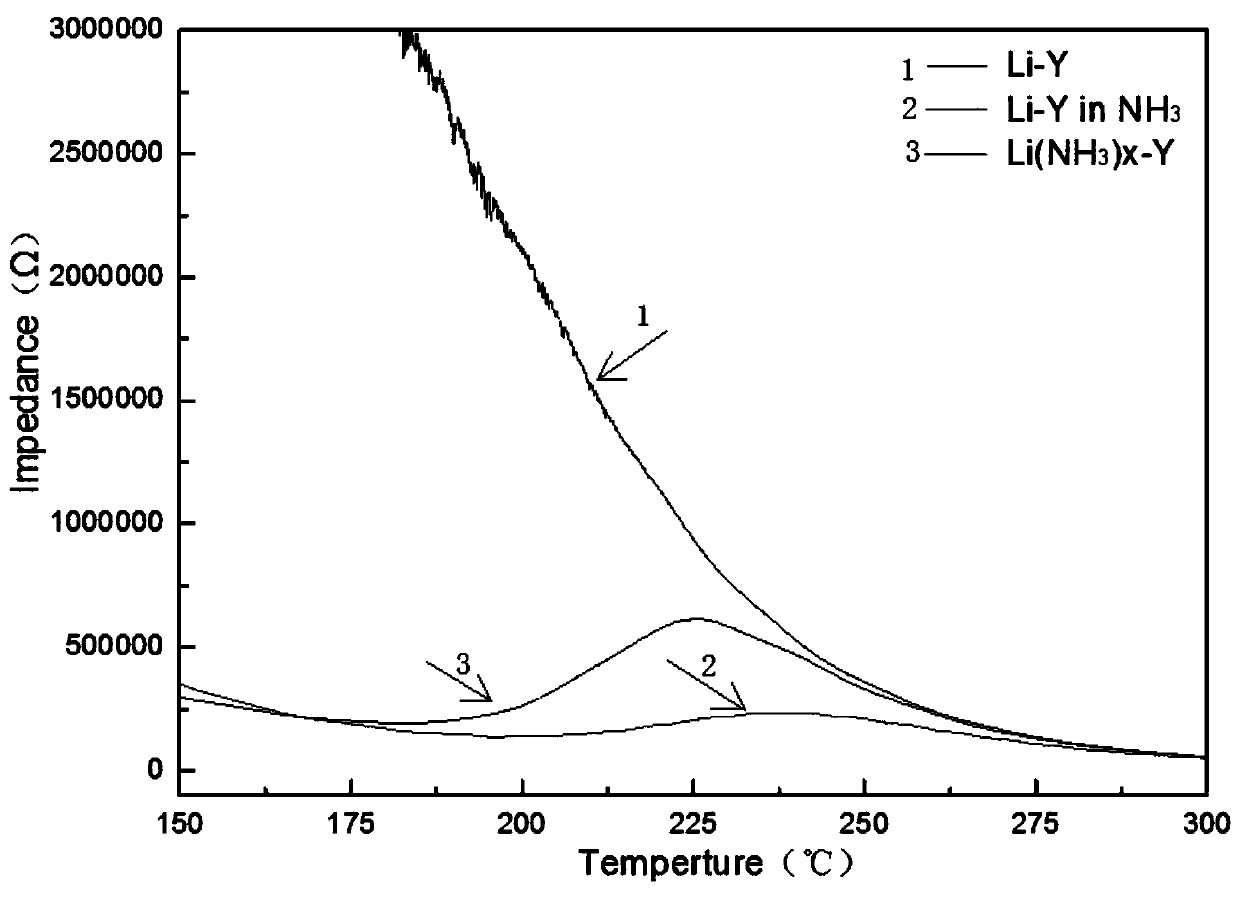

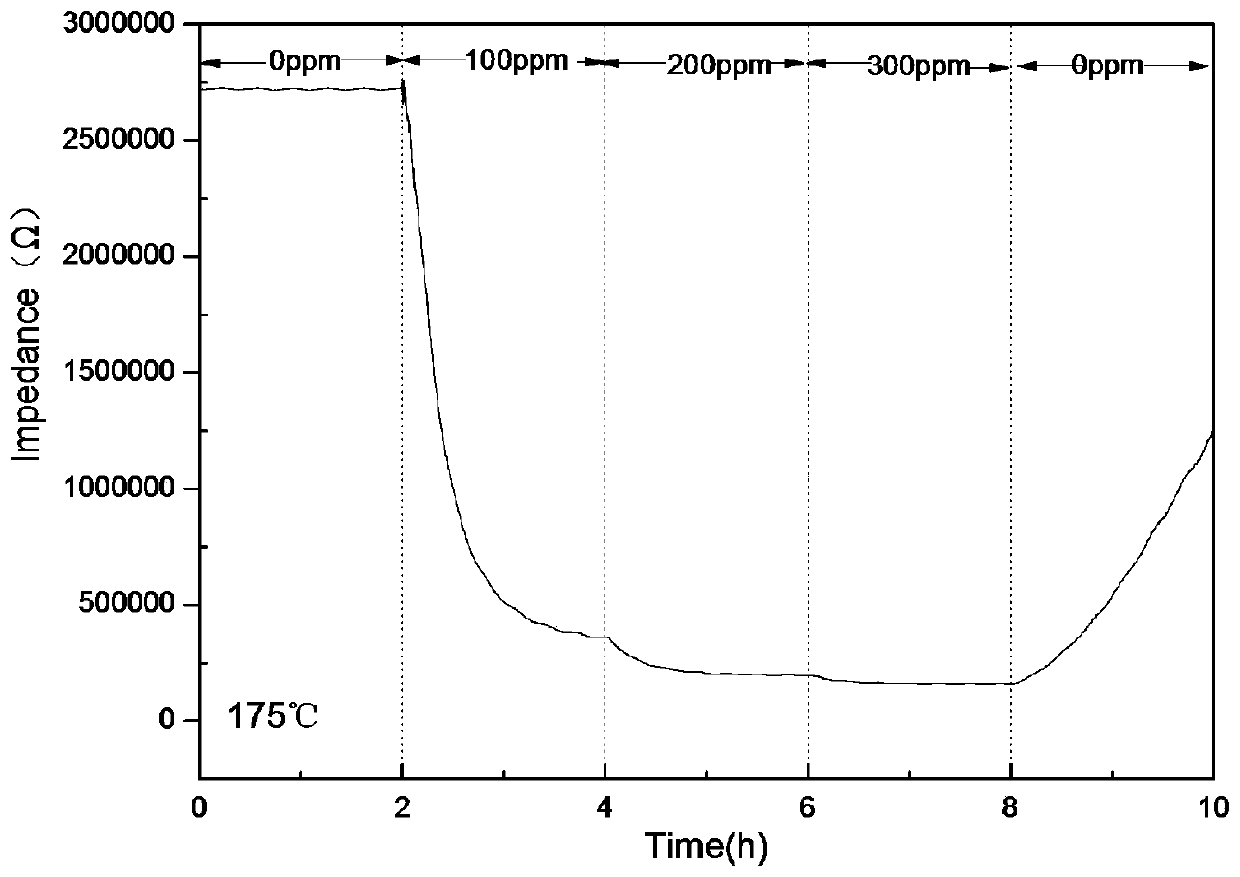

[0035] A Y-type zeolite ammonia sensor based on cation exchange is prepared by soaking the zeolite-based sensor in a lithium chloride solution with a concentration of 0.1mol / L and exchanging it on a shaker for 12 hours.

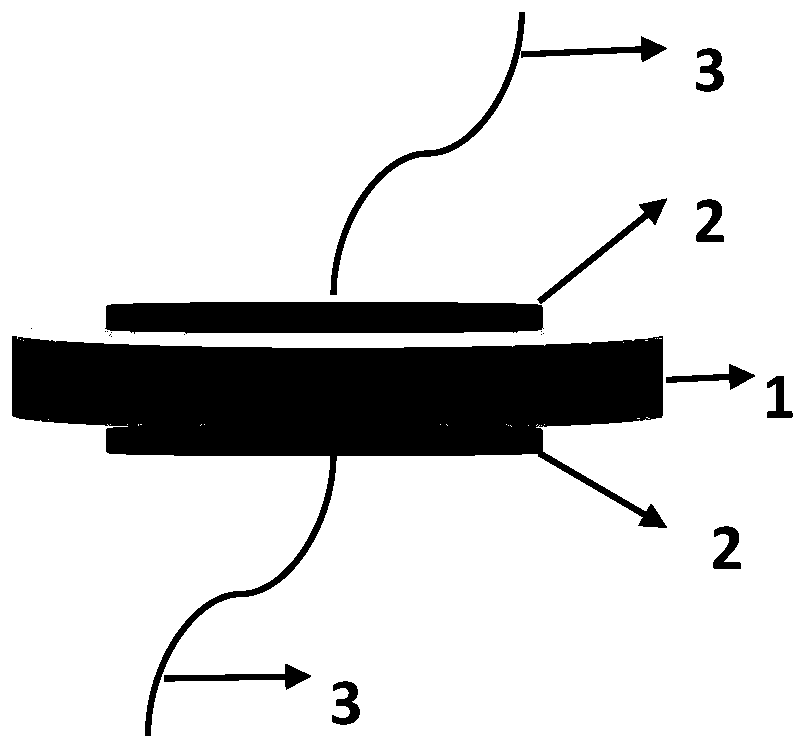

[0036] Specifically, it is prepared by the following preparation method: Weigh a certain amount of Y-type zeolite and put it into a mold, press it into a circular sheet by an oil press, and sinter it in a high-temperature furnace at 600 ° C for 2 hours in an air environment to obtain an area of 40 mm. 2 Zeolite flakes with a thickness of 1.0mm;

[0037] Use screen printing technology to print silver paste on both sides of the zeolite sheet as electrodes, and the area of the electrodes on both sides is 30mm 2 , with a thickness of 50 μm, and dot silver wires on the middle of the electrodes on both sides with silver paste, first dry at 80°C for 0.5h, and then sinter in a high-temperature furnace at 600°C for 2h to form electrodes and electrode leads on both...

Embodiment 2

[0040] The only difference from Example 1 is that the cation-exchange-based Y-type zeolite ammonia sensor performs liquid-phase ion exchange by soaking the zeolite-based sensor in a lanthanum nitrate solution with a concentration of 0.1mol / L, and the others are the same as in Example 1. It is not repeated here, and the present embodiment makes a 3+ Ion-exchange Y-type zeolite ammonia sensor.

Embodiment 3

[0042] The only difference from Example 1 is that the sintering temperature of the zeolite flakes is 590°C, the sintering time is 1.5h, and the area of the zeolite flakes is 42mm 2 , thickness is 0.9mm, electrode area is 28mm 2 , with a thickness of 50 μm, first dry at 85°C for 0.8h after spotting the silver wire with silver paste, and then sinter at 590°C for 2.5h in a high-temperature furnace; the concentration of lithium chloride solution is 0.15mol / L, and the others are the same as in Example 1 , which will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com