A preparation method of hydrogen sensitive element based on orthorhombic phase molybdenum oxide nanoribbon

A technology of sensitive components and nanobelts, applied in the direction of material resistance, can solve the problems of rough morphology of nanomaterials, unsuitable for mass production, poor process repeatability, etc., to achieve low cost, short preparation cycle, good repeatability and selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

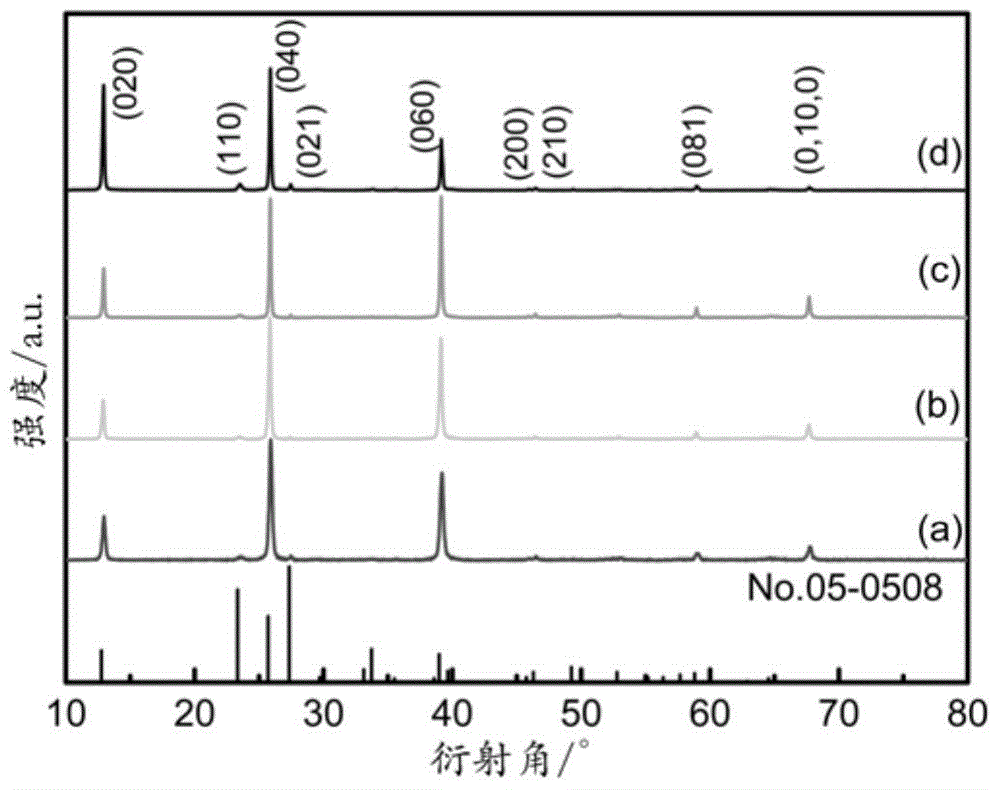

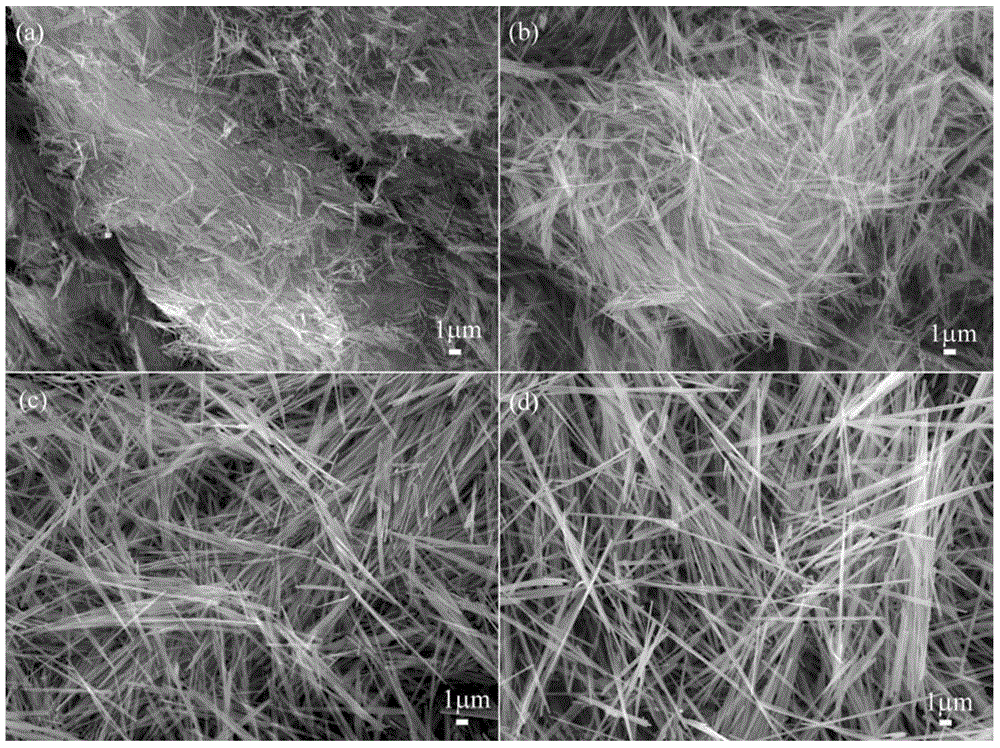

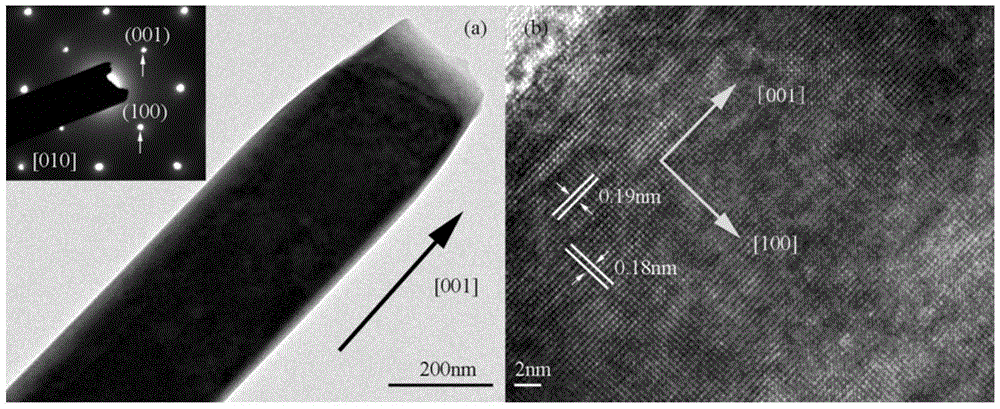

[0035] Preparation of molybdenum oxide nanoribbons A

[0036] 1) In a 50ml reaction vessel, 2.4195g Na 2 MoO 4 2H 2 Add O to 32.75ml deionized water, the concentration of molybdenum element is about 0.305mol / L, stir slowly to fully dissolve the molybdenum salt;

[0037] 2) Under electromagnetic stirring, slowly pour 6.25ml of 65% concentrated nitric acid into the above solution to form an acid solution, the concentration of nitric acid is 2.5mol / L;

[0038] 3) After being fully mixed, transfer the above solution to a hydrothermal reaction kettle, and react at a temperature of 120°C for 12 hours;

[0039] 4) After the reaction is finished, air-cool the reactor to room temperature, filter and separate, and dry at 70°C for 10 hours to obtain orthorhombic molybdenum trioxide nanoribbon powder.

Embodiment 2

[0041] Preparation of molybdenum oxide nanoribbons B

[0042] 1) In a 50ml reaction vessel, 2.4195g Na 2 MoO 4 2H 2 Add O to 32.75ml deionized water, the concentration of molybdenum element is about 0.305mol / L, stir slowly to fully dissolve the molybdenum salt;

[0043] 2) Under electromagnetic stirring, slowly pour 6.25ml of 65% concentrated nitric acid into the above solution to form an acid solution, the concentration of nitric acid is 2.5mol / L;

[0044] 3) After being fully mixed, transfer the above solution to a hydrothermal reaction kettle, and react at a temperature of 160°C for 12h;

[0045] 4) After the reaction is finished, air-cool the reactor to room temperature, filter and separate, and dry at 70°C for 10 hours to obtain orthorhombic molybdenum trioxide nanoribbon powder.

Embodiment 3

[0047] Preparation of molybdenum oxide nanoribbons C

[0048] 1) In a 50ml reaction vessel, 2.4195g Na 2 MoO 4 2H 2 Add O to 32.75ml deionized water, the concentration of molybdenum element is about 0.305mol / L, stir slowly to fully dissolve the molybdenum salt;

[0049] 2) Under electromagnetic stirring, slowly pour 6.25ml of 65% concentrated nitric acid into the above solution to form an acid solution, the concentration of nitric acid is 2.5mol / L;

[0050] 3) After being fully mixed, transfer the above solution to a hydrothermal reaction kettle, and react at a temperature of 180°C for 12 hours;

[0051] 4) After the reaction is finished, air-cool the reactor to room temperature, filter and separate, and dry at 70°C for 10 hours to obtain orthorhombic molybdenum trioxide nanoribbon powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com