Preparation method of oat bean curd sticks

A technology of bean curd sticks and oats, which is applied in the field of soybean product processing, can solve the problems of single nutritional components and taste, ordinary bean curd sticks are fragile, and poor health care functions, and achieve the effect of simple process equipment, good stability and less friability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

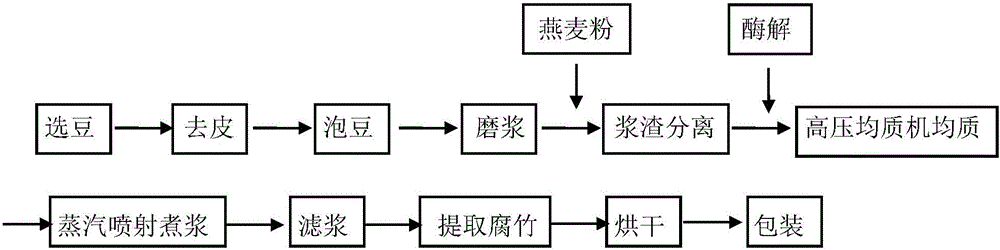

[0023] The preparation method of oat bean curd stick, the method comprises the following steps:

[0024] (1) After peeling the soybeans, soak them in water at a temperature of 30-35°C for 12-15 hours, add weak alkaline water to refine the beans after soaking them, and then separate the pulp residue to obtain raw soybean milk;

[0025] (2) Wash and dry the oats, steam and fry them, and grind them to make cooked oatmeal flour;

[0026] (3) Mix the soymilk prepared in step (1) with the oat flour prepared in step (2) to obtain a mixed solution. The amount of oat flour added is 10-30% of the total solution mass, and flavor is added to the mixed solution Enzymolysis with protease is carried out to obtain enzymolysis solution, the above-mentioned method is that the amount of protein added is 0.2% of the total mass, the enzymolysis temperature is 50-55°C, the enzymolysis time is 3-4 hours, and the enzymolysis pH is 6-7. The enzymolysis solution is subjected to high-pressure homogeniz...

Embodiment 1

[0035] 1 Materials and methods

[0036] 1.1 Materials and reagents

[0037] soybean

Kennong cultivated by Heilongjiang Academy of Agricultural Sciences

oat

commercially available

flavor protease

Ruiyang Biological Co., Ltd.

[0038] 1.2 Main instruments and equipment

[0039]

[0040] 2 Technological process (see the attached figure in the abstract):

[0041] 2.1 Sensory evaluation standard test

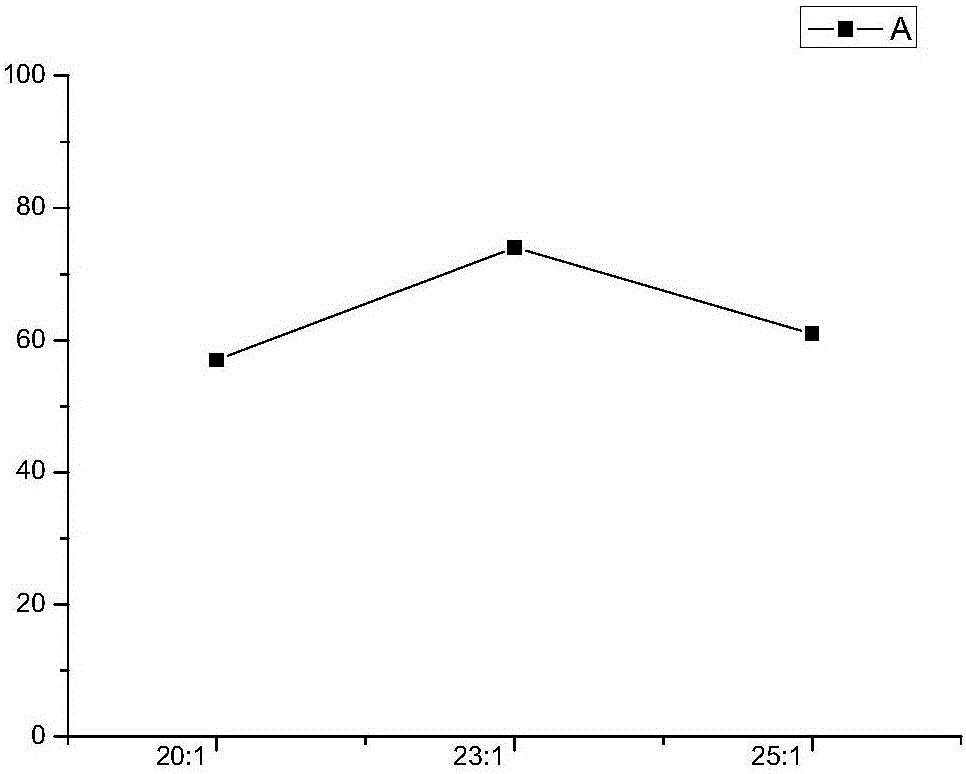

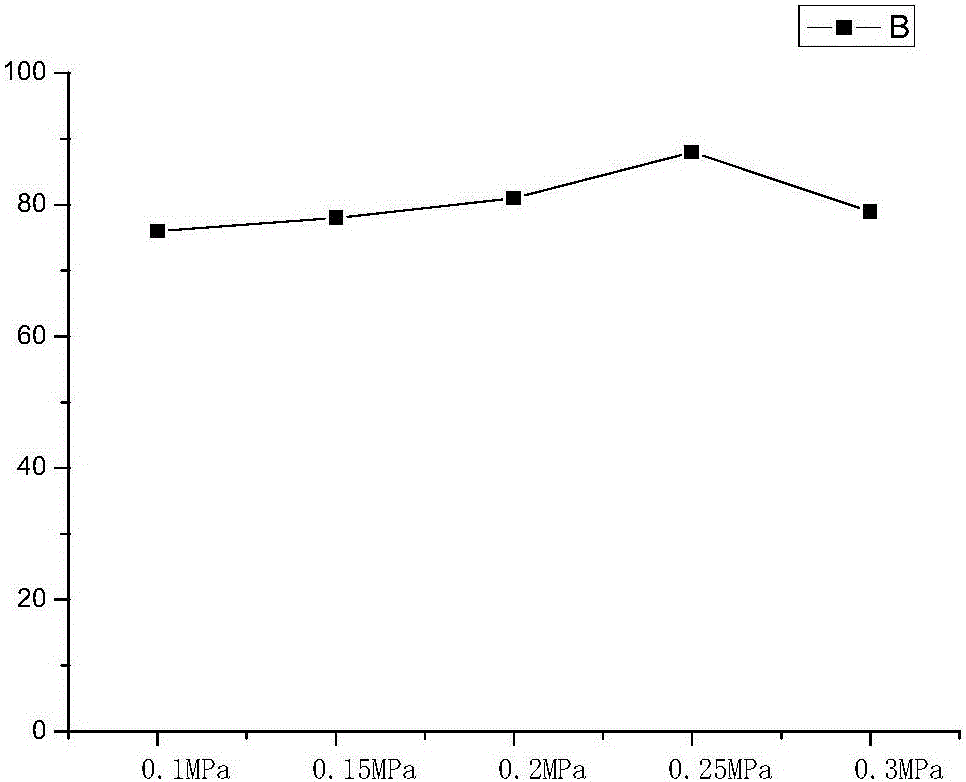

[0042] The influence of three factors, the addition ratio of soybean milk and oat flour, the cooking pressure, and the cooking temperature, on the quality of oat bean curd sticks were studied, and sensory evaluation was carried out. See Table 2-1 for the sensory evaluation criteria for oat bean curd sticks.

[0043] Table 2-1 Sensory scoring criteria

[0044]

[0045] 2.2 Orthogonal experiment

[0046] Through a single factor test, three factors were chosen: the proportion of soybean milk and oat flour, the cooking pressure, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com