Preparation method of compound nano-emulsion

A nanoemulsion and solution technology, applied in the field of food processing, can solve problems such as difficult maintenance and poor stability of polyphenols, and achieve the effects of expanding the application range, shortening the process production cycle, and reducing blood lipids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

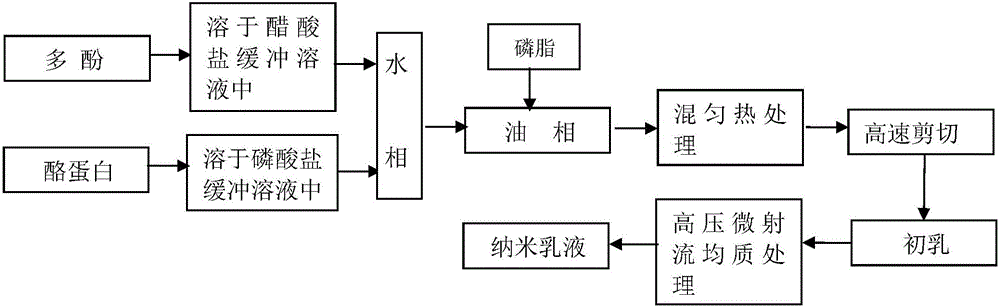

[0016] A method for preparing a composite nanoemulsion, the method comprising the following steps: (1) fixing the molar ratio of polyphenols and casein to 9-11:1, dissolving polyphenols in an acetate buffer solution with pH 4.5, and casein Dissolve in pH 7.0, 0.2 mol / L phosphate buffer solution to make a polyphenol protein solution with a concentration of 1.5-2.5 mg / mL; mix polyphenol casein solution with water at a ratio of 1:18-20 (v / v ) mixed to obtain a water phase; (2) adding 5% phospholipids to soybean oil to obtain an oil phase; (3) mixing the water phase and the oil phase and performing heat treatment to obtain a mixed phase, the heat treatment temperature is 40-50°C, heat treatment The time is 15-25min. After heat treatment, the primary emulsion is obtained by high-speed shearing. The high-speed shearing speed is 8000-10000r / min, and the time is 3-5min. For the nanoemulsion, the micro-jet homogenization pressure is 500 bar to 1000 bar, the time is 1-5 min, and the num...

Embodiment 1

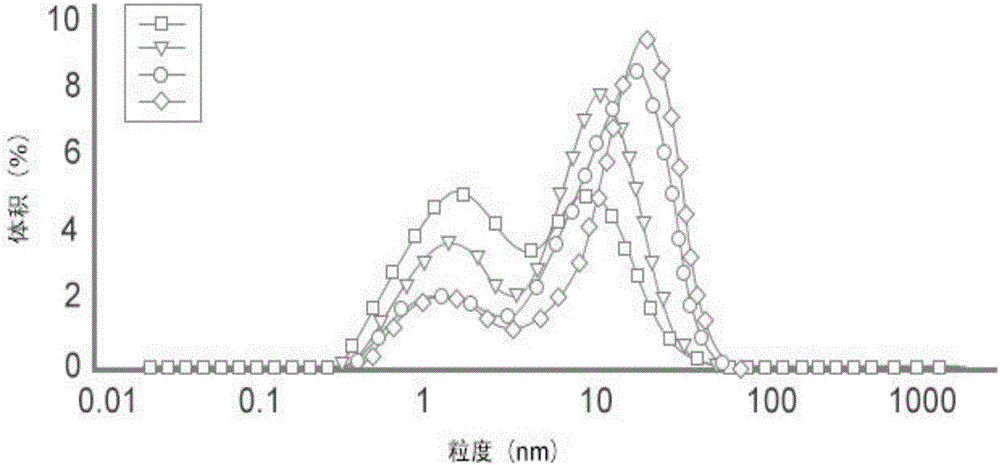

[0023] Fix the molar ratio of tea polyphenols / casein at 9:1, dissolve tea polyphenols in acetate buffer solution with pH 4.5, and dissolve casein in pH 7.0, 0.2 mol / L phosphate buffer solution to make a concentration of 1.5 mg / mL casein solution. Mix tea polyphenols and casein solution at 1:18 (v / v) at room temperature to obtain an aqueous phase; add 5% soybean lecithin (phosphatidylcholine content ≈72%) to soybean oil to obtain an oil phase; mixed with soybean oil and heat-treated at 40°C for 25 minutes. After heat treatment, high-speed shearing at 8000r / min for 5 minutes was performed to obtain colostrum. The obtained colostrum was subjected to high-pressure micro-jet homogenization treatment at 500bar for 2 minutes. 3 times, a polyphenol-casein composite nanoemulsion was obtained, the particle size see figure 2 . The polyphenol-casein composite nanoemulsion prepared by the invention has the characteristics of high stability, high digestion and absorption rate and high n...

Embodiment 2

[0025] Fix the molar ratio of tea polyphenols / casein at 9:1, dissolve tea polyphenols in acetate buffer solution with pH 4.5, and dissolve casein in pH 7.0, 0.2 mol / L phosphate buffer solution to make a concentration of 1.5 mg / mL casein solution. Mix tea polyphenols and casein solution at 1:18 (v / v) at room temperature to obtain an aqueous phase; add 5% soybean lecithin (phosphatidylcholine content ≈72%) to soybean oil to obtain an oil phase; mixed with soybean oil and heat-treated at 45°C for 20 minutes. After heat treatment, high-speed shearing at 9000r / min for 4 minutes to obtain colostrum, and the obtained colostrum was subjected to high-pressure micro-jet homogenization treatment at 800bar for 3 minutes. 3 times, a polyphenol-casein composite nanoemulsion was obtained, the particle size see figure 2 . The polyphenol-casein composite nanoemulsion prepared by the invention has the characteristics of high stability, high digestion and absorption rate and high nutritional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com