Dual-drive high-gravity rotating packed bed

A supergravity rotating, packed bed technology, applied in chemical/physical/physical-chemical mobile reactors, chemical instruments and methods, solvent extraction, etc., to achieve the effect of prolonging mixing time, obvious atomization effect, and improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

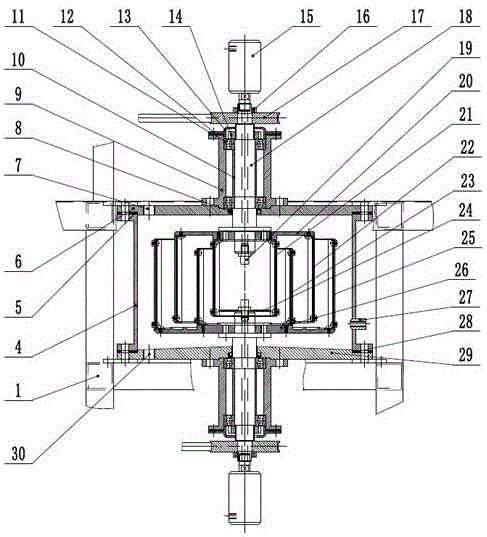

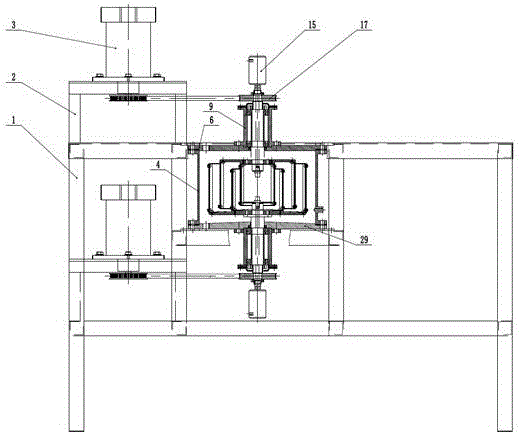

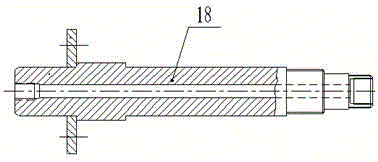

[0036] Embodiment 1: as Figure 1-7 As shown, a dual-drive high-gravity rotating packed bed includes a power transmission structure, a liquid spraying structure, a rotating shaft structure, a liquid mass transfer structure and a fixed component structure; the power transmission structure is two sets of symmetrical power transmission mechanisms up and down; the liquid The spraying structure includes a rotary joint 15, a nozzle 19 and a splash plate 24, and the liquid spraying structure is two sets of upper and lower symmetrical structures; the rotating shaft structure includes an oil seal 8, a bearing 11, an end cover sealing ring 12, a bearing end cover 13, and a round nut I14 , rotating shaft 18; the rotating shaft structure is two sets of symmetrical structures up and down; the liquid mass transfer structure includes an upper rotating disc 20, an upper disc inner ring 21, an upper disc outer ring 22, a lower disc inner ring 23, and a lower disc outer ring 25 , the lower rota...

Embodiment 2

[0042] Embodiment 2: as Figure 1-7 As shown, a dual-drive high-gravity rotating packed bed includes a power transmission structure, a liquid spraying structure, a rotating shaft structure, a liquid mass transfer structure and a fixed component structure; the power transmission structure is two sets of symmetrical power transmission mechanisms up and down; the liquid The spraying structure includes a rotary joint 15, a nozzle 19 and a splash plate 24, and the liquid spraying structure is two sets of upper and lower symmetrical structures; the rotating shaft structure includes an oil seal 8, a bearing 11, an end cover sealing ring 12, a bearing end cover 13, and a round nut I14 , rotating shaft 18; the rotating shaft structure is two sets of symmetrical structures up and down; the liquid mass transfer structure includes an upper rotating disc 20, an upper disc inner ring 21, an upper disc outer ring 22, a lower disc inner ring 23, and a lower disc outer ring 25 , the lower rota...

Embodiment 3

[0054] Embodiment 3: As described in the implementation case 2, only the motor on the lower floor is started, and the motor on the upper floor does not run. The nozzle 19 at the bottom of the rotating shaft 18 of the upper set of rotating shaft structure is removed, and the upper rotary joint 15 is set as the air outlet. 27. When the gas is fed and other conditions remain unchanged, the equipment can be converted into a baffled high-gravity rotating packed bed suitable for gas-liquid reactions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com