Preparation method of fe-doped carbon nitride/mesoporous graphite carbon composite catalyst and product and application

A composite catalyst and graphitic carbon technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve polymer oxidation, limited application, high price, etc. problem, to achieve the effect of simple operation, wide range of pH application and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

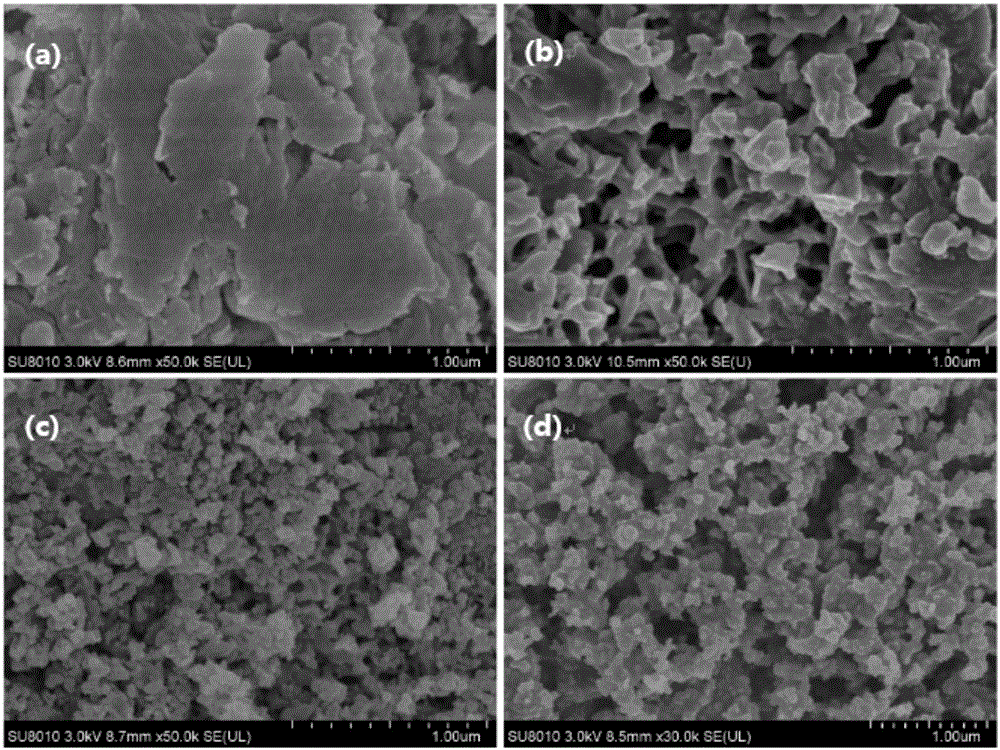

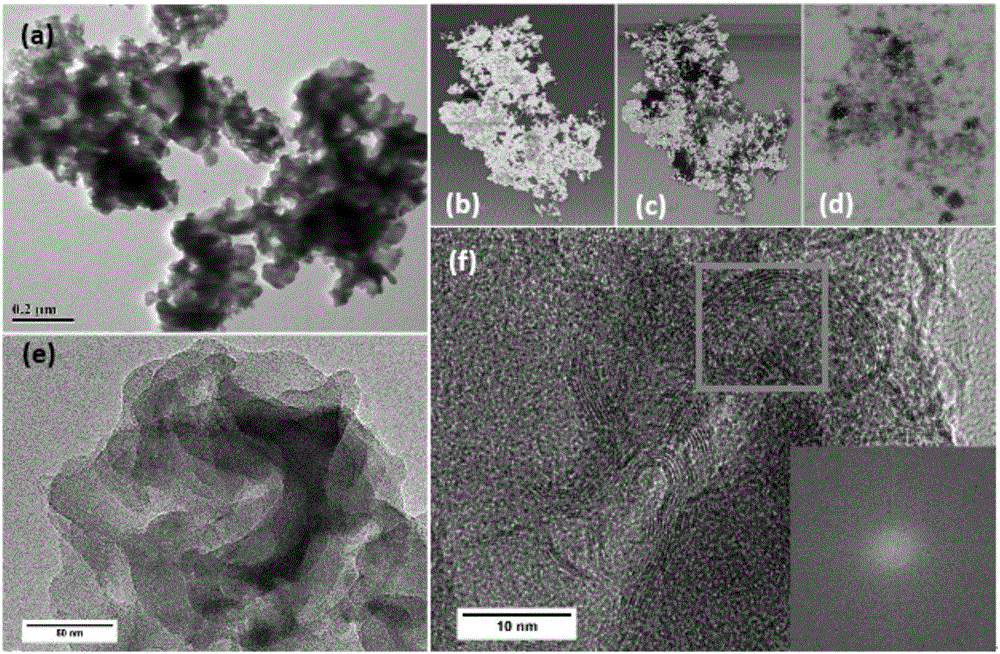

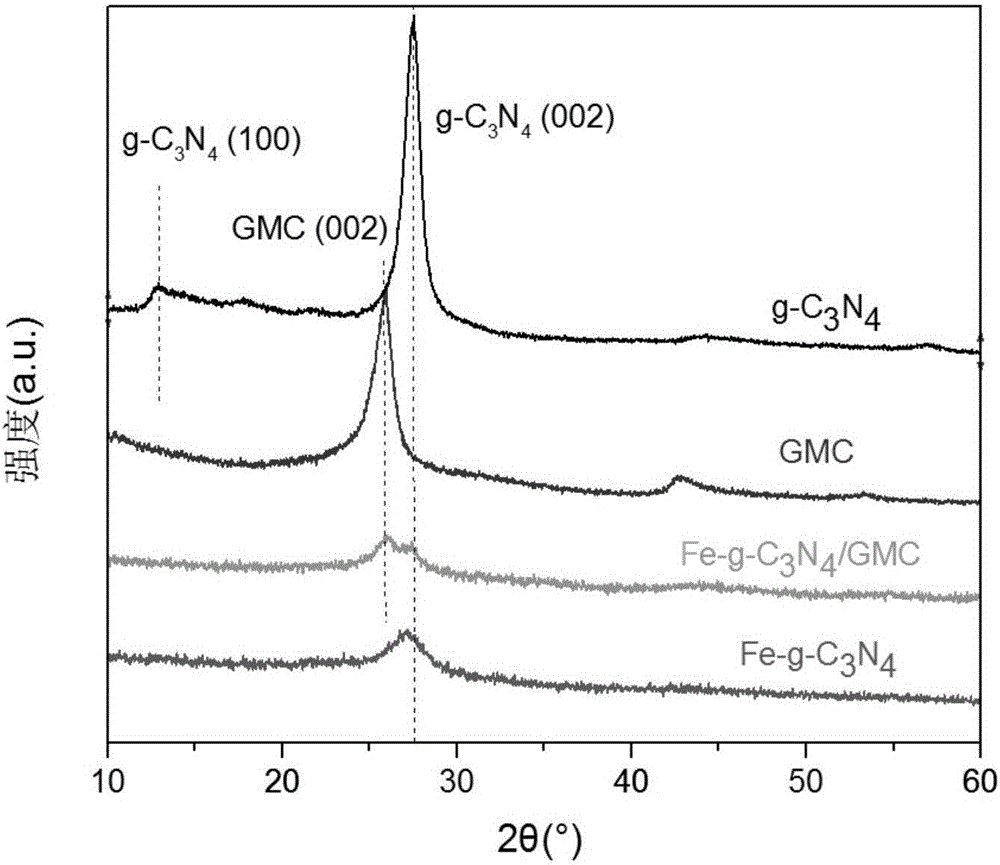

[0044] Add 20mL of deionized water into a 50mL beaker, heat it to 80°C with a heater with temperature control function, add 1g of dicyandiamide, stir it until it is completely dissolved, and then add a certain amount of ferric chloride hexahydrate according to the data in Table 1 , continue stirring for 1 h, and then add 0.1 g of mesoporous graphitic carbon. Heat to 120°C and continue to stir until the water evaporates completely. The above mixture was slightly ground to obtain a black powder, which was placed in a tube furnace and calcined under nitrogen atmosphere for 3 hours according to the temperature in Table 1, with a heating rate of 10°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com