Rolling and lubricating automatic fluid preparation method for cold rolled strip

A technology of automatic liquid preparation and cold rolling, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., which can solve the problems of daily maintenance equipment without automatic control start and stop, unstable lubrication performance and product surface quality, emulsion Concentration fluctuations and other issues can be reduced to reduce rolling oil consumption, meet maintenance and use requirements, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

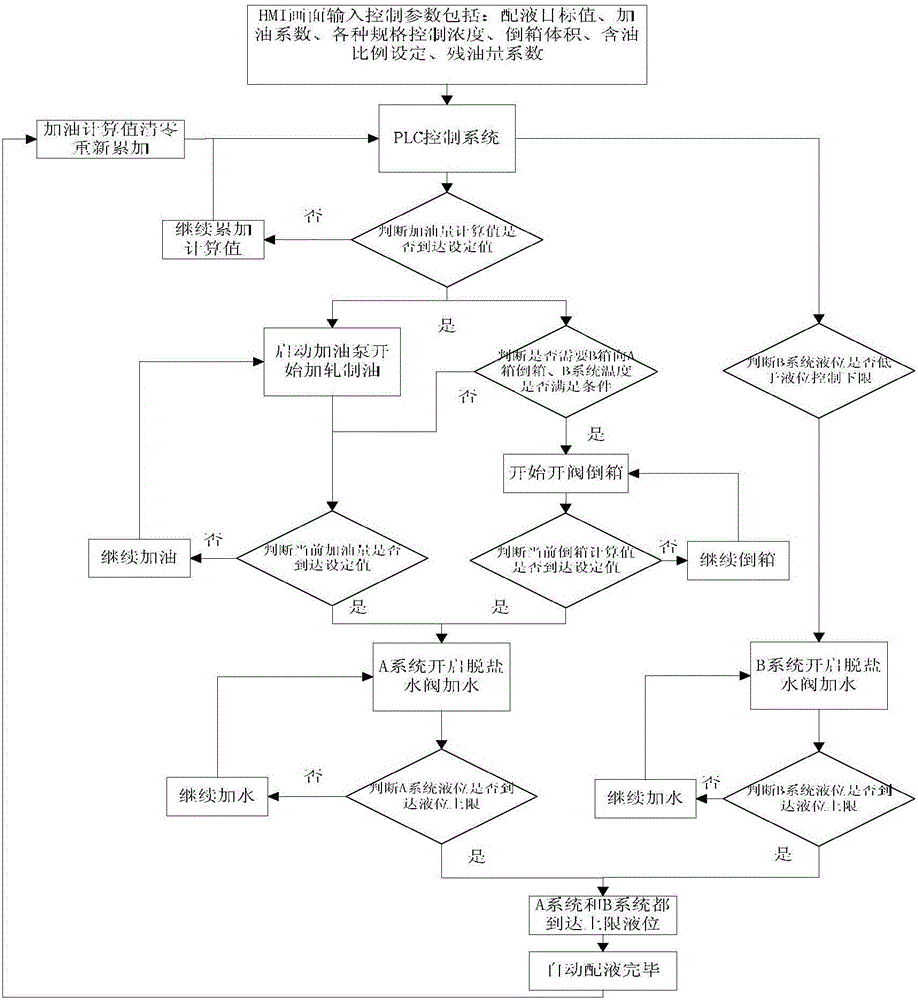

Method used

Image

Examples

Embodiment Construction

[0025] A method for calculating the consumption of rolling oil on the surface of a cold-rolled steel strip can automatically calculate the consumption of rolling oil on the surface of a single coil of steel strip and the rolling oil consumed in the T time period according to the length of the steel strip produced. The specific calculation method is as follows:

[0026] 1) Measure the amount of residual oil on the surface of smooth cold-rolled sheets of various thicknesses at different rolling speeds, and calculate the average value C of the amount of residual oil on the surface of cold-rolled sheets of various specifications 光 ;

[0027] 2) Measure the amount of residual oil on the surface of pitted cold-rolled plates of various thicknesses at different rolling speeds, and calculate the average value C of the residual oil on the surface of cold-rolled plates of various specifications 麻 ;

[0028] 3) Calculation method of surface rolling oil consumption: according to the lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com